824

Champagne. From grapes to foam

Champagne - sparkling wine made by the secondary fermentation of wine. The name of the drink takes its name from the Champagne region in France.

While the term "champagne" is often used sparkling wine producers in many countries and areas (for example, in California, Canada and Russia), to use it only in relation to wine produced in the Champagne region. Under the auspices of the "Committee Interprofessionnel du sparkling wines" it was developed a comprehensive set of rules and regulations for all wines from this region. These rules are designed to ensure the production of high quality product. The regulations marked the most suitable place for growing grapes, the most suitable varieties of grapes - Champagne is made from a single variety or a mixture comprising not more than three grape varieties: Chardonnay (fr. Chardonnay), Pinot Noir (fr. Pinot noir) and Pinot mёne (Fr. . pinot meunier). It is also determined by the rather long list of requirements, defining the main aspects of grape growing. Among these rules: pruning the vines, the harvest of the vineyard, the degree of pressing the grapes. Only if the wine meets all these requirements, may be placed on the bottle the name "Champagne". The rules developed by the Committee of sparkling wines submitted for the approval of the French "National Institute of denominations of origin»

From the materials Pedivikii

User mcsdwarken spied as do currently Champagne

Champagne vineyards. Then it all starts.

2. On the sunny slopes of Champagne grapes growing 3 - Chardonnay (chardonnay), Pinot Noir (pino noir) and Pinot Meunier (pinot meunier).

3. There are various gradations of quality grapes. A special commission determines the status of each of the Champagne region, based on the quality of soil, amount of sun, and other criteria. Status Grand Cru (Grand Cru) in Champagne assigned only 10 villages.

4. grape pinot noir. Each grape variety has a different shape of the leaf and bush, and experienced winemakers easily distinguished varieties, without even seeing the berries.

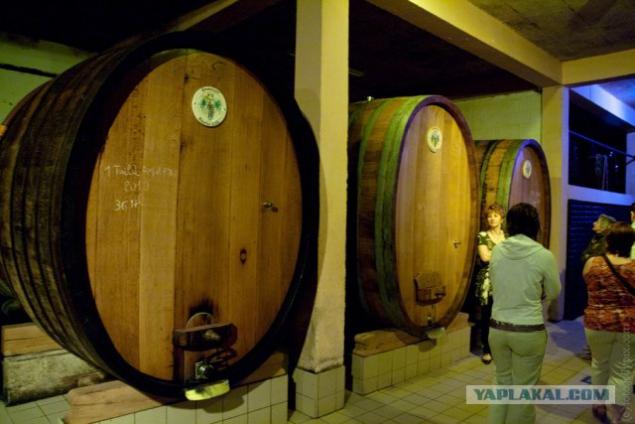

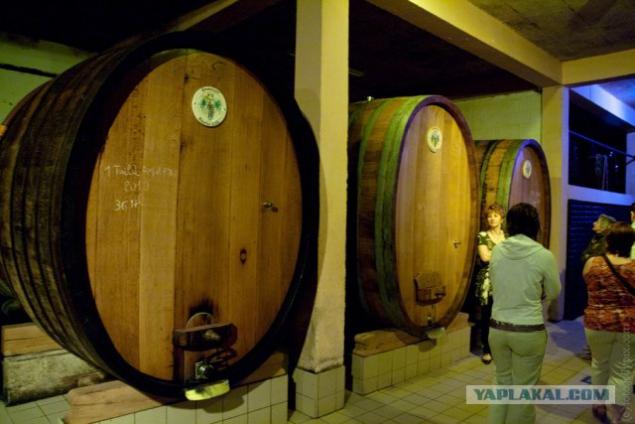

5. Ripe grapes are harvested in August (this year spring is very hot, so the collection will begin in mid-July). After harvesting the grapes crushed and the resulting juice is poured into large barrels to ferment and turn into wine.

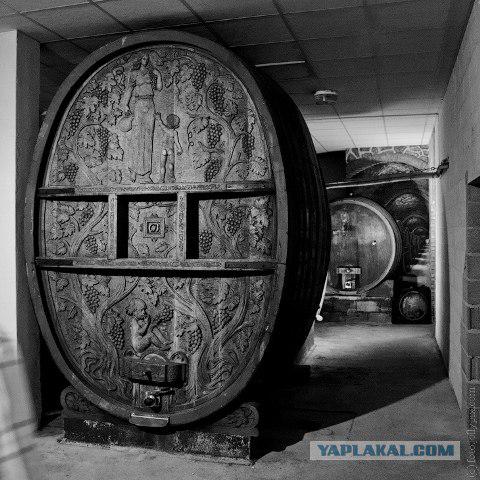

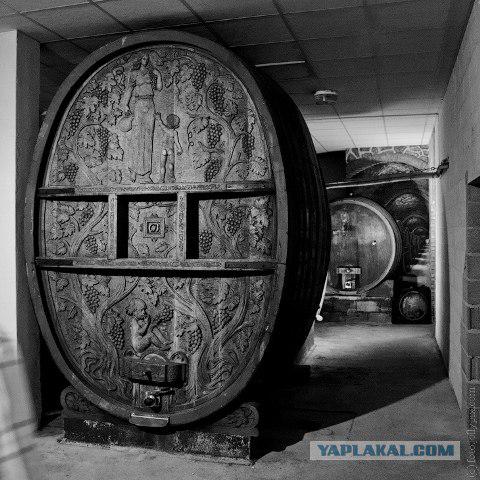

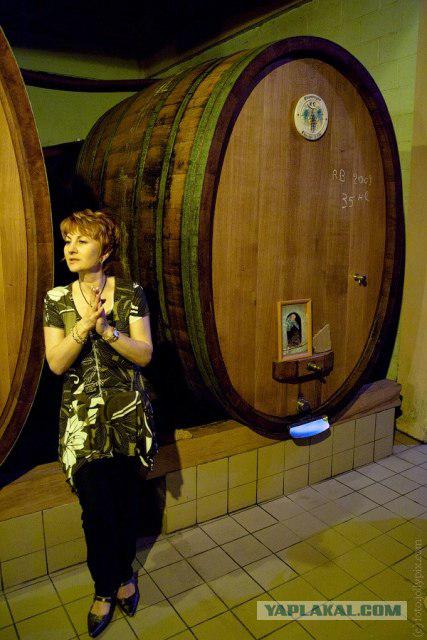

6. Some barrels are perfect by themselves. To do this drawing master took half the time and polbochki wine.

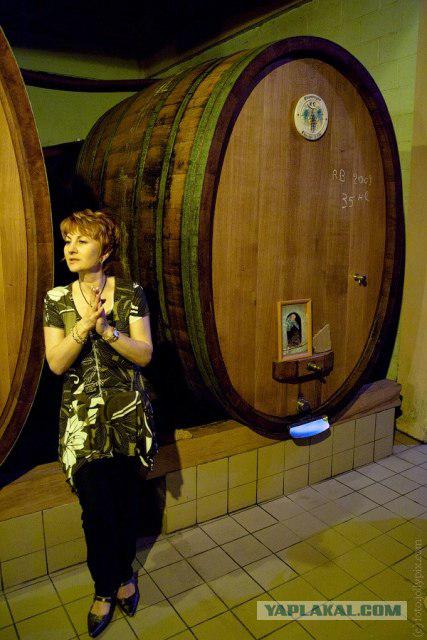

7. The wine is aged in barrels for 3 to 6 months. Each barrel is assigned a unique number, which can be found in the records of a grape wine and then a year.

8. From time to time it is necessary to clean the inside of the barrel. Fortunately, these barrels are quite large, so I just saw through the hole, climbs into a man, and clean. In the photo, standing on a barrel, just seen this cleaner.

9. That that settles on the walls of the barrel - some acid. It is bad taste, as I understood from the French explanation.

10. After 6 months, the wine barrels are opened and evaluated by a specialist that most wines. Different wines are blended to create a unique taste of champagne. A mixture of the wine is bottled.

11. The wine in the bottle is added the sugar and yeast. Depending on the amount of added sugar, champagne will be different in sweetness. The most popular champagne - is, of course, Brut (5-15mg / L). There are natural brut or extra brut, which is prepared absolutely no added sugar (0-5mg / l). All the familiar to the new year sweet champagne called demi-sec (35-55mg / l), but it is not popular and is produced is not all winemakers

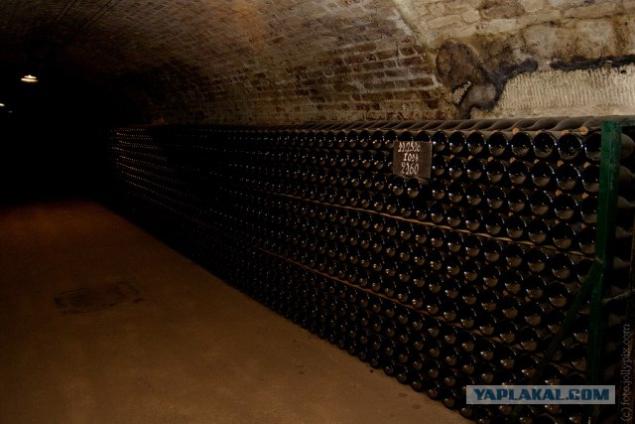

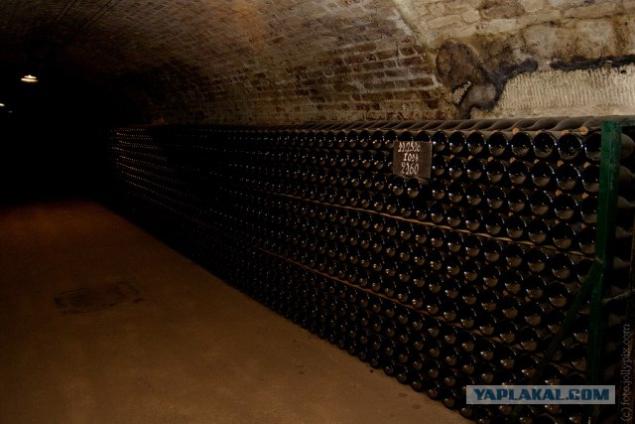

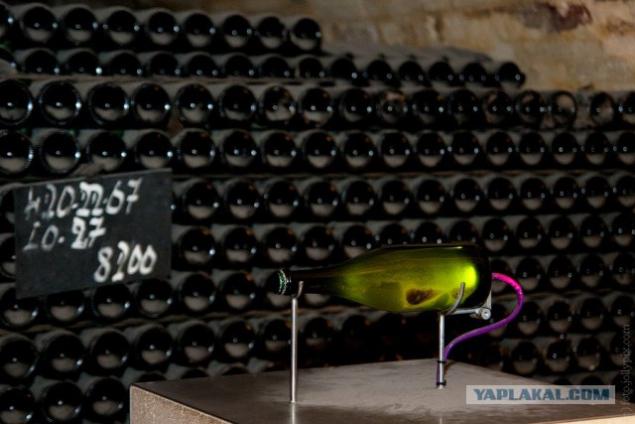

12. The mixture of wine yeast and sugar is placed in a cold dark cellars. Yeast eat the sugar and produce carbon dioxide, which then will have to bubble in the glass.

13. Champagne stored in the cellars for at least 1, 5 years. More can be less - Nini

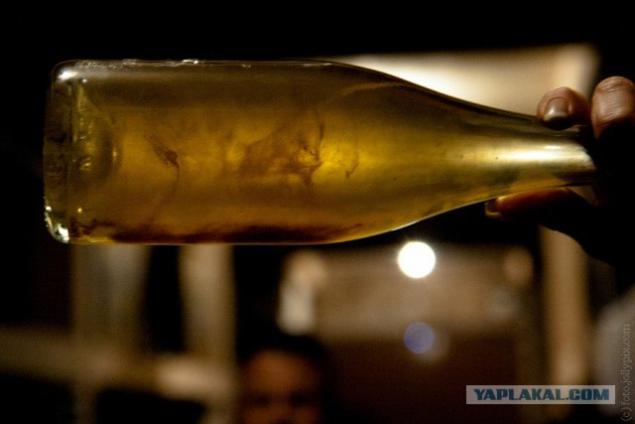

14. vintage, collectible and other interesting varieties (eg millezim - champagne from the wine just one year) are stored longer, in principle, almost indefinitely.

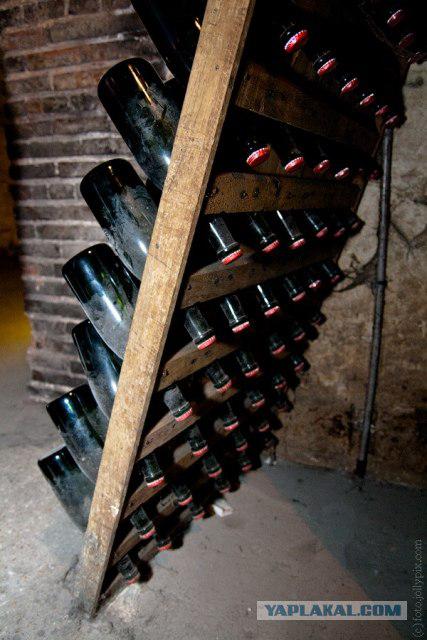

15. Yeast disperse the pressure in the bottle up to 6 atmospheres. Not all kinds of bottles withstand such treatment, so it happens that sometimes explode. Yes, it's the champagne on the floor

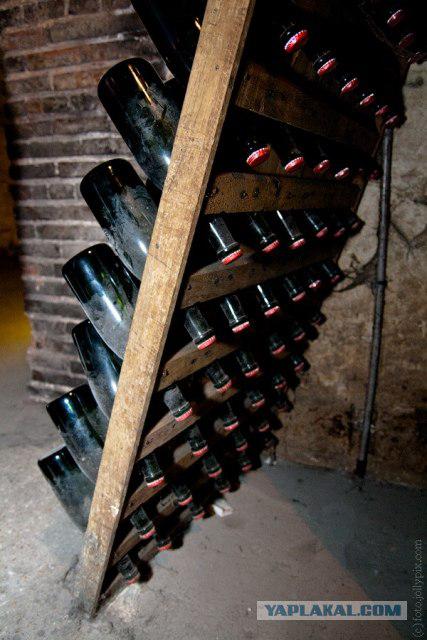

16. In this age of modern technology, a real cork stopper is used only at the last stage of production, and more as a tribute to tradition. At the stage of maturation of champagne close ordinary beer cap.

17. amount of dust can determine the age (and price) of champagne.

18. After the time required for the maturation of the dead zombie yeast form an unpleasant aftertaste in the bottle. The precipitate was recovered to give champagne transparency and purity.

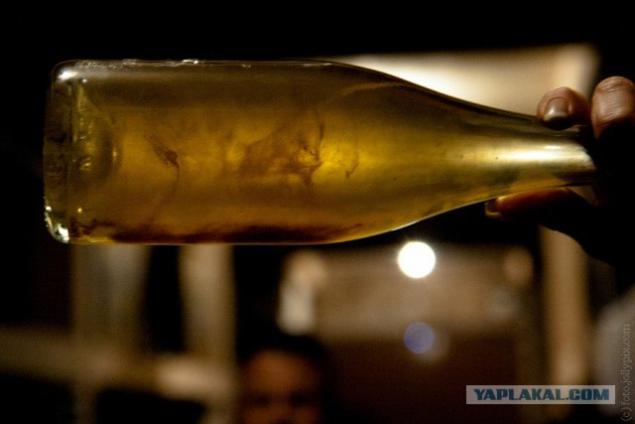

19. The old, long lying bottles sediment can be so dense and compacted, it is necessary to shake the bottle so that it lagged behind the walls.

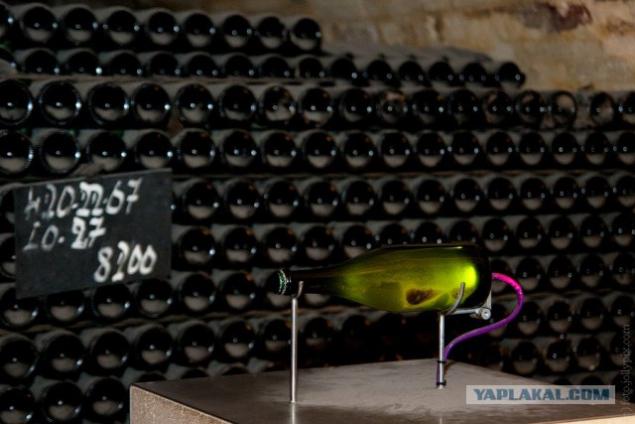

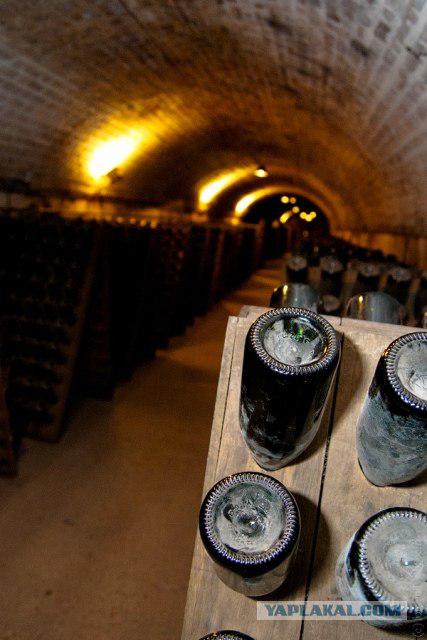

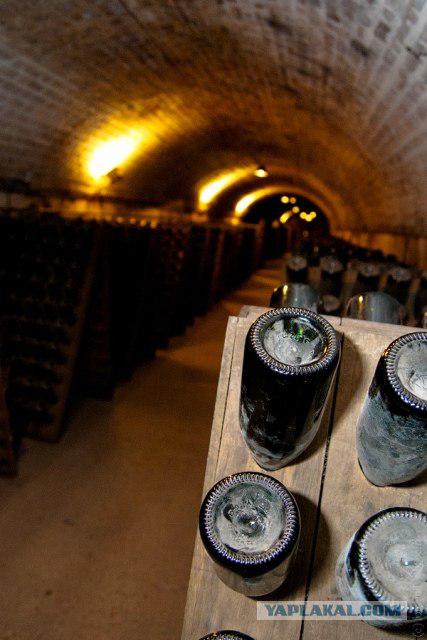

20. To remove the sediment bottle is turned upside down on a special board. The precipitate thus settles to the neck of the bottle.

21. Bottles posted so you need every day a little bit to turn to precipitate uniformly flocked from the cover, but not on the cover. In the 19th century, this work makes a special person remyuer. Every day he turned slightly each bottle. Nowadays, non-human robots perform this chore.

22. After a couple of months, riddling, sediment has accumulated in the neck and should be removed.

23. Previously, removing the precipitate was slow and difficult process. Now everything has become much easier - the bottle neck is frozen and the bottle is opened. Pressure knocks frozen sediment.

24. Before installing the final cork in the bottle is poured syrup. Syrup - a wine with sugar, exactly the same mixture from which it is made champagne.

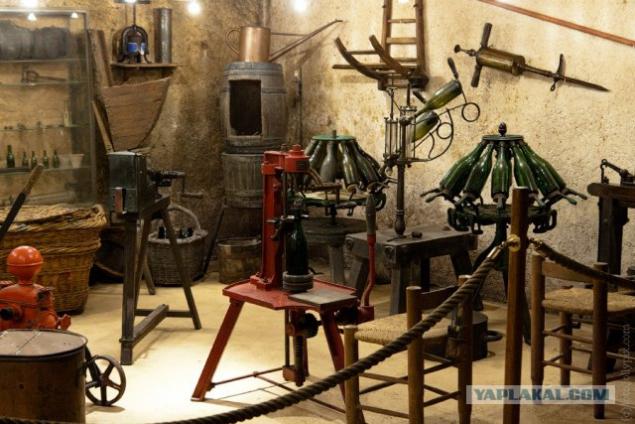

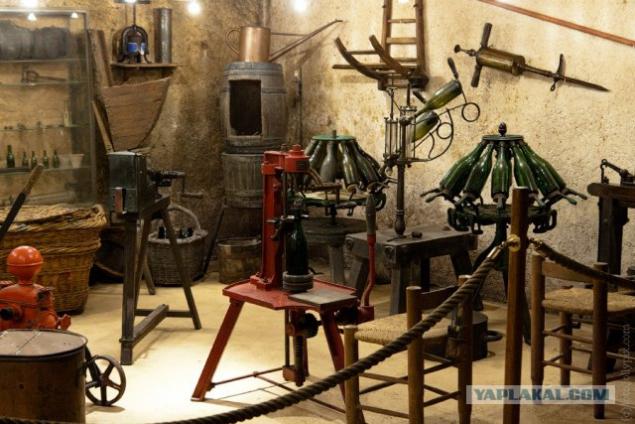

25. And before that rolled here on the bottle. There is in this something of BDSM. And now all automated production lines.

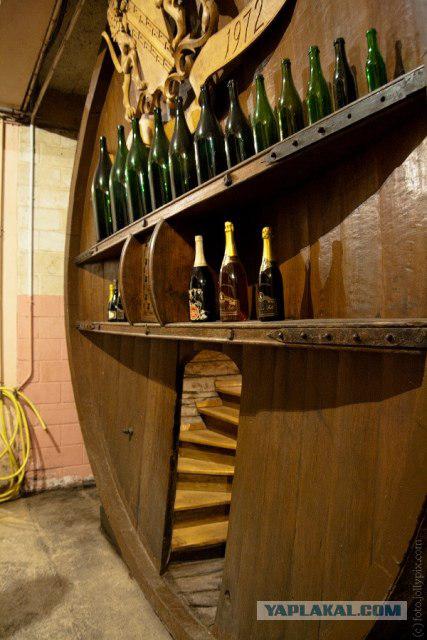

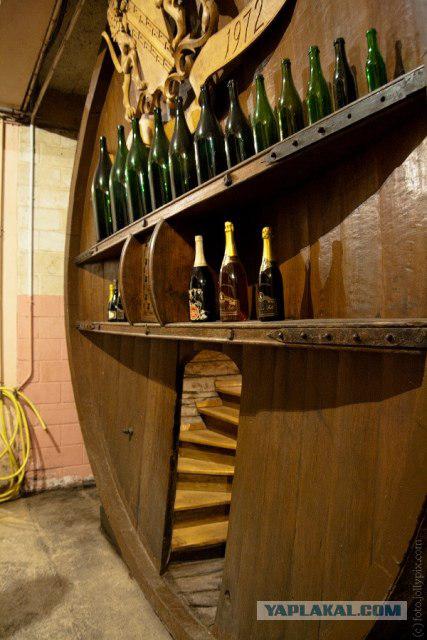

26. Huge barrel, inside there is a table and chairs. You can taste the champagne A top placing the whole range of sizes of bottles of champagne. Each bottle has its own name, such as zherobom or Napoleon.

27. A votre santé!

Source:

While the term "champagne" is often used sparkling wine producers in many countries and areas (for example, in California, Canada and Russia), to use it only in relation to wine produced in the Champagne region. Under the auspices of the "Committee Interprofessionnel du sparkling wines" it was developed a comprehensive set of rules and regulations for all wines from this region. These rules are designed to ensure the production of high quality product. The regulations marked the most suitable place for growing grapes, the most suitable varieties of grapes - Champagne is made from a single variety or a mixture comprising not more than three grape varieties: Chardonnay (fr. Chardonnay), Pinot Noir (fr. Pinot noir) and Pinot mёne (Fr. . pinot meunier). It is also determined by the rather long list of requirements, defining the main aspects of grape growing. Among these rules: pruning the vines, the harvest of the vineyard, the degree of pressing the grapes. Only if the wine meets all these requirements, may be placed on the bottle the name "Champagne". The rules developed by the Committee of sparkling wines submitted for the approval of the French "National Institute of denominations of origin»

From the materials Pedivikii

User mcsdwarken spied as do currently Champagne

Champagne vineyards. Then it all starts.

2. On the sunny slopes of Champagne grapes growing 3 - Chardonnay (chardonnay), Pinot Noir (pino noir) and Pinot Meunier (pinot meunier).

3. There are various gradations of quality grapes. A special commission determines the status of each of the Champagne region, based on the quality of soil, amount of sun, and other criteria. Status Grand Cru (Grand Cru) in Champagne assigned only 10 villages.

4. grape pinot noir. Each grape variety has a different shape of the leaf and bush, and experienced winemakers easily distinguished varieties, without even seeing the berries.

5. Ripe grapes are harvested in August (this year spring is very hot, so the collection will begin in mid-July). After harvesting the grapes crushed and the resulting juice is poured into large barrels to ferment and turn into wine.

6. Some barrels are perfect by themselves. To do this drawing master took half the time and polbochki wine.

7. The wine is aged in barrels for 3 to 6 months. Each barrel is assigned a unique number, which can be found in the records of a grape wine and then a year.

8. From time to time it is necessary to clean the inside of the barrel. Fortunately, these barrels are quite large, so I just saw through the hole, climbs into a man, and clean. In the photo, standing on a barrel, just seen this cleaner.

9. That that settles on the walls of the barrel - some acid. It is bad taste, as I understood from the French explanation.

10. After 6 months, the wine barrels are opened and evaluated by a specialist that most wines. Different wines are blended to create a unique taste of champagne. A mixture of the wine is bottled.

11. The wine in the bottle is added the sugar and yeast. Depending on the amount of added sugar, champagne will be different in sweetness. The most popular champagne - is, of course, Brut (5-15mg / L). There are natural brut or extra brut, which is prepared absolutely no added sugar (0-5mg / l). All the familiar to the new year sweet champagne called demi-sec (35-55mg / l), but it is not popular and is produced is not all winemakers

12. The mixture of wine yeast and sugar is placed in a cold dark cellars. Yeast eat the sugar and produce carbon dioxide, which then will have to bubble in the glass.

13. Champagne stored in the cellars for at least 1, 5 years. More can be less - Nini

14. vintage, collectible and other interesting varieties (eg millezim - champagne from the wine just one year) are stored longer, in principle, almost indefinitely.

15. Yeast disperse the pressure in the bottle up to 6 atmospheres. Not all kinds of bottles withstand such treatment, so it happens that sometimes explode. Yes, it's the champagne on the floor

16. In this age of modern technology, a real cork stopper is used only at the last stage of production, and more as a tribute to tradition. At the stage of maturation of champagne close ordinary beer cap.

17. amount of dust can determine the age (and price) of champagne.

18. After the time required for the maturation of the dead zombie yeast form an unpleasant aftertaste in the bottle. The precipitate was recovered to give champagne transparency and purity.

19. The old, long lying bottles sediment can be so dense and compacted, it is necessary to shake the bottle so that it lagged behind the walls.

20. To remove the sediment bottle is turned upside down on a special board. The precipitate thus settles to the neck of the bottle.

21. Bottles posted so you need every day a little bit to turn to precipitate uniformly flocked from the cover, but not on the cover. In the 19th century, this work makes a special person remyuer. Every day he turned slightly each bottle. Nowadays, non-human robots perform this chore.

22. After a couple of months, riddling, sediment has accumulated in the neck and should be removed.

23. Previously, removing the precipitate was slow and difficult process. Now everything has become much easier - the bottle neck is frozen and the bottle is opened. Pressure knocks frozen sediment.

24. Before installing the final cork in the bottle is poured syrup. Syrup - a wine with sugar, exactly the same mixture from which it is made champagne.

25. And before that rolled here on the bottle. There is in this something of BDSM. And now all automated production lines.

26. Huge barrel, inside there is a table and chairs. You can taste the champagne A top placing the whole range of sizes of bottles of champagne. Each bottle has its own name, such as zherobom or Napoleon.

27. A votre santé!

Source: