791

Production of oak barrels for cognac

Barrel. How much of this word for the producer of cognac. After all, in the dark depths of the oak container comes inaccessible to the human eye sacrament of maturing of the drink. Filled in a barrel grape alcohol, absorbs the energy of a multi-year wood, saturate it smells and changes its color. And the longer the grape spirit remains locked in oak chains, the deeper, thinner, multi-valued and become more diverse flavor unleashed the finished product.

37 photos via kukuksumushu

1. Do not be afraid to call the magic process of converting pure and clear as the morning dew, grape alcohol, just to cool the coil distillation cube in the dark amber liquid, filled with sunlight warms the vineyards. Not only as sorcery can be called the process of changing the taste of alcohol with a pronounced fruity brandy soaked in a countless variety of flavors and colors, and nutmeg, coffee beans and vanilla, fruit and chocolate. It is this magic of transformation presents us with a bouquet of aromas and long aftertaste changing brandy, something for which he is loved and appreciated.

Procedures and production technology cognac strictly defined and strictly regulated. Oak Barrel was to grow in France. In cooperage production of oak barrels used two regions of France: Limousin and Tronse.

2. We sergeydolya dima_chatrov and passed along the entire manufacturing process of oak barrels for cognac in the world's largest cooperage production - factory Seguin Moreau.

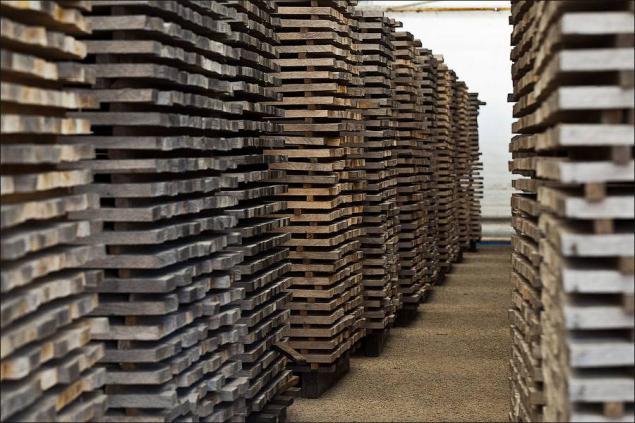

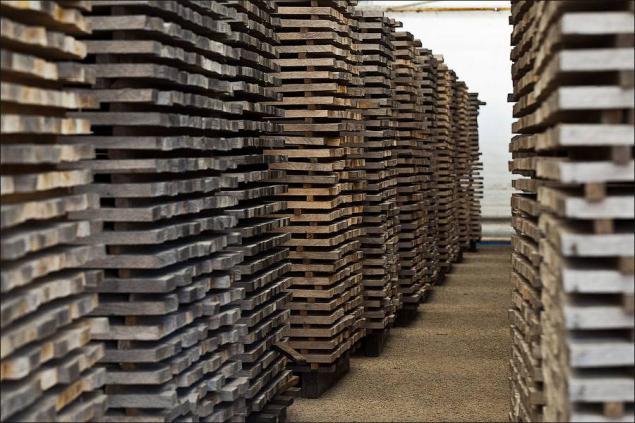

3. Cut as sandwiches are dried oak barrels for eight months in vivo

4. Then napilivayutsya not the same plank of which will be collected barrel. These tablets are dried for approximately 3-4 months. Wood surface darkens

5. drying technology, occasionally watered boards

6. dima_chatrov tasting the oak juice, trying to identify the taste characteristics of the future cognac

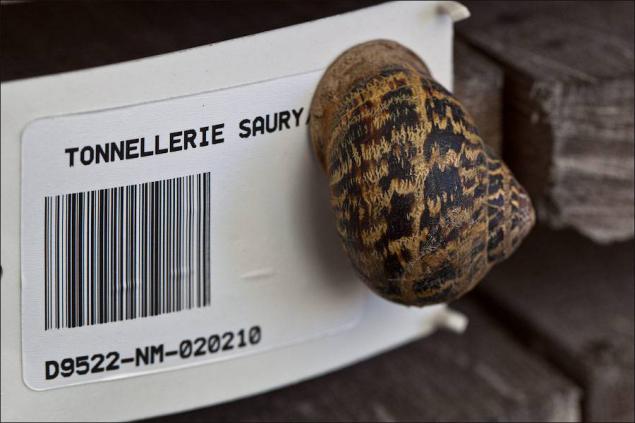

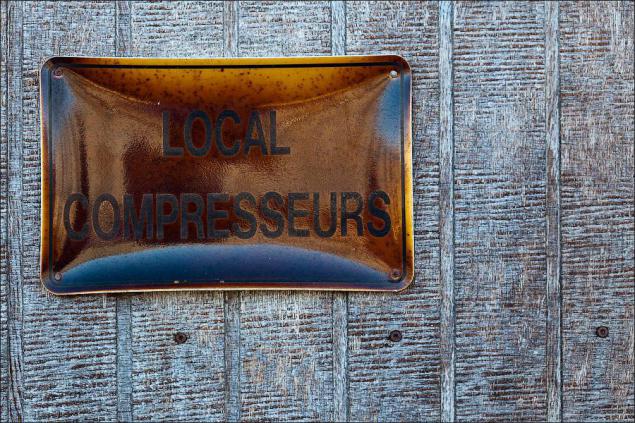

7. All the pieces of wood carefully sorted for flaws and defects. All storage areas are marked

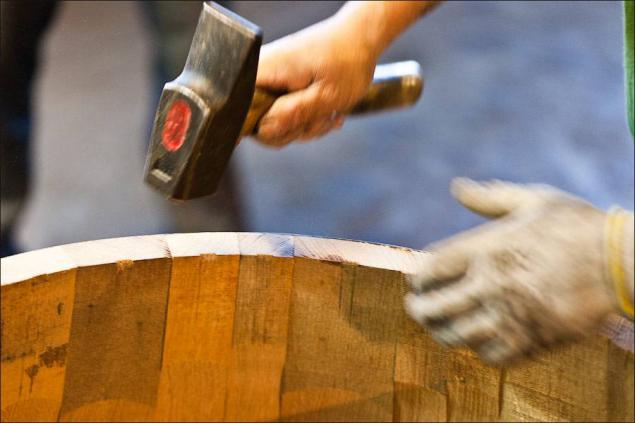

8. After drying the preform and the process planed assembly. First, collect the barrels on one side of the metal hoop

9.

10. These half-drums placed on a roasting pan for roasting the inner surface. Fire softens the surface of the oak and by heat treatment of glucose contained in the wood structure is formed layer of sugar.

11. The degree of roasting greatly affects the taste of cognac.

12.

13.

14. going to wrap the lower part of the barrel

15. The barrel is turned and fired again

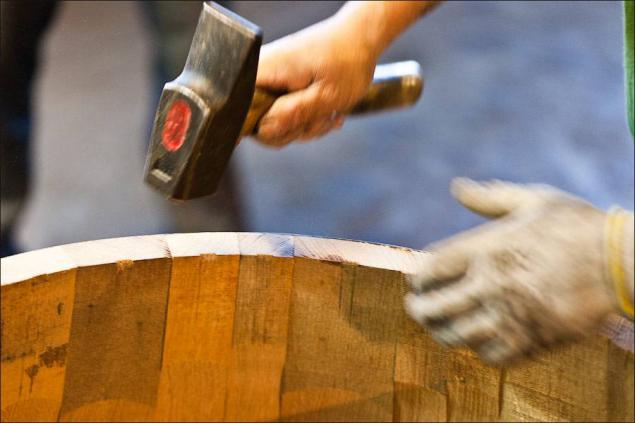

16. Finally tightly constricted locking hoops

17. grinds

18.

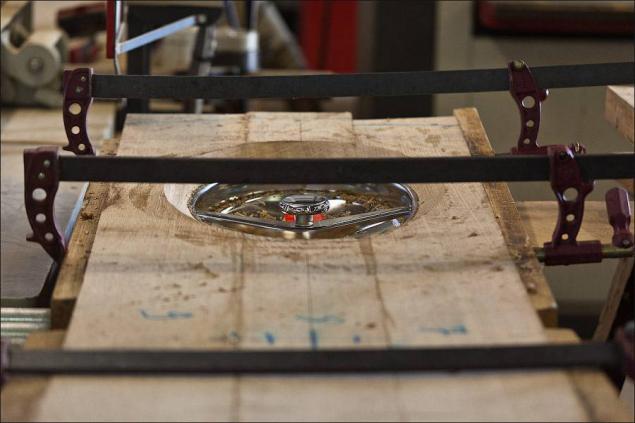

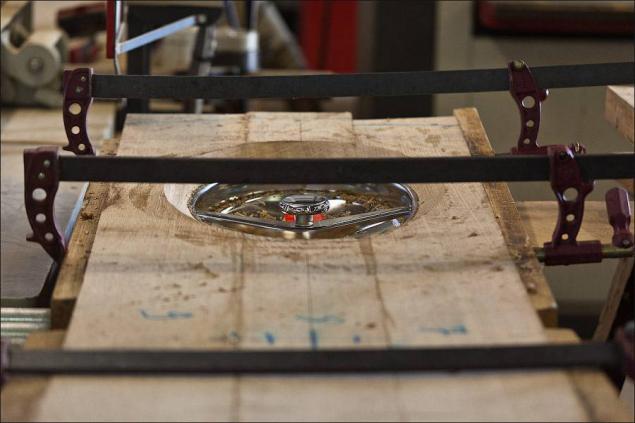

19. Mounted bottoms

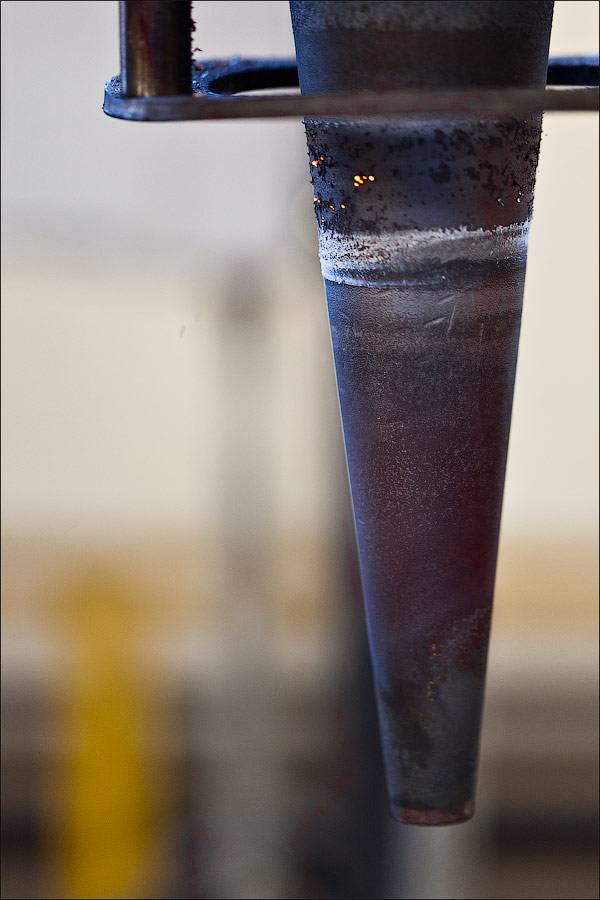

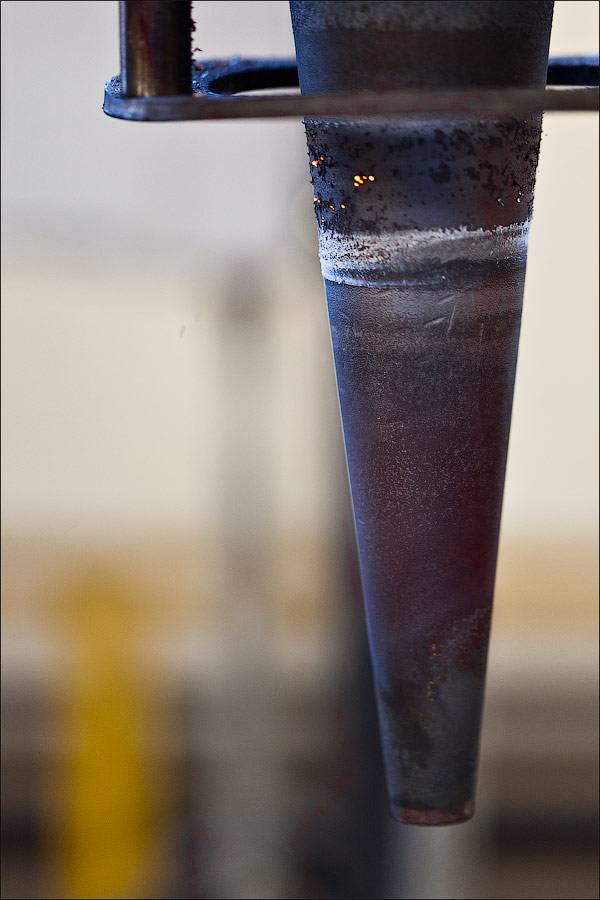

20. Warmly warmed tip is burned filler opening

21.

22. Its conical shape and size is fixed

23.

24.

25.

26. The barrel is equipped with a plug

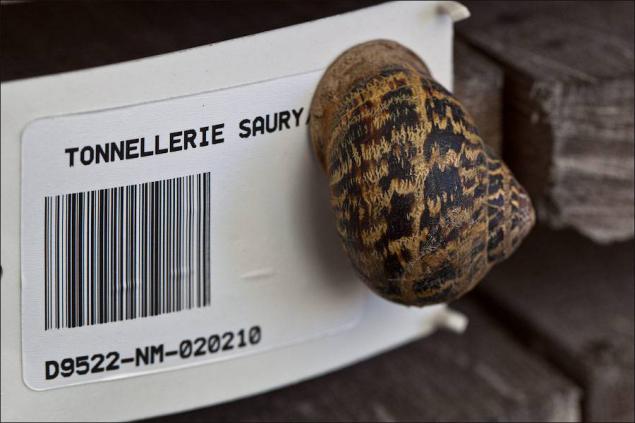

27. Instruction on application

28. The matter of pride to be glued

29. And the barrel goes to the warehouse of finished products

30. In a separate workshop collect huge barrels for wine

31.

32.

33.

34.

35.

36

37

Source:

37 photos via kukuksumushu

1. Do not be afraid to call the magic process of converting pure and clear as the morning dew, grape alcohol, just to cool the coil distillation cube in the dark amber liquid, filled with sunlight warms the vineyards. Not only as sorcery can be called the process of changing the taste of alcohol with a pronounced fruity brandy soaked in a countless variety of flavors and colors, and nutmeg, coffee beans and vanilla, fruit and chocolate. It is this magic of transformation presents us with a bouquet of aromas and long aftertaste changing brandy, something for which he is loved and appreciated.

Procedures and production technology cognac strictly defined and strictly regulated. Oak Barrel was to grow in France. In cooperage production of oak barrels used two regions of France: Limousin and Tronse.

2. We sergeydolya dima_chatrov and passed along the entire manufacturing process of oak barrels for cognac in the world's largest cooperage production - factory Seguin Moreau.

3. Cut as sandwiches are dried oak barrels for eight months in vivo

4. Then napilivayutsya not the same plank of which will be collected barrel. These tablets are dried for approximately 3-4 months. Wood surface darkens

5. drying technology, occasionally watered boards

6. dima_chatrov tasting the oak juice, trying to identify the taste characteristics of the future cognac

7. All the pieces of wood carefully sorted for flaws and defects. All storage areas are marked

8. After drying the preform and the process planed assembly. First, collect the barrels on one side of the metal hoop

9.

10. These half-drums placed on a roasting pan for roasting the inner surface. Fire softens the surface of the oak and by heat treatment of glucose contained in the wood structure is formed layer of sugar.

11. The degree of roasting greatly affects the taste of cognac.

12.

13.

14. going to wrap the lower part of the barrel

15. The barrel is turned and fired again

16. Finally tightly constricted locking hoops

17. grinds

18.

19. Mounted bottoms

20. Warmly warmed tip is burned filler opening

21.

22. Its conical shape and size is fixed

23.

24.

25.

26. The barrel is equipped with a plug

27. Instruction on application

28. The matter of pride to be glued

29. And the barrel goes to the warehouse of finished products

30. In a separate workshop collect huge barrels for wine

31.

32.

33.

34.

35.

36

37

Source: