717

Device propeller ship

It was inspired recent threads about diesel and electric locomotives ...

(I envy the authors of these topics and a little sorry that fate has brought me to this technique)

I decided to post 12 pictures with his work about the ship's propeller.

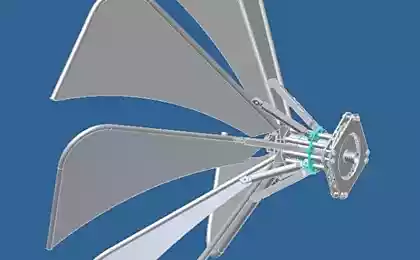

He has the ability to change the angle of attack of the blades during rotation. (Probably like a helicopter propeller)

That's decided to show its components in order to become immediately clear principle of the unit changes the angle. If anyone is interested.

If you can- beforehand please do not break the topic.

in fact, the ship was under repair. Among the various works was supposed to make out, to fathom the gaps and then collect obratno.Tipa regulations.

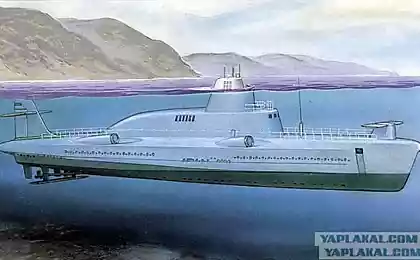

Now the boat itself (from which the screw)

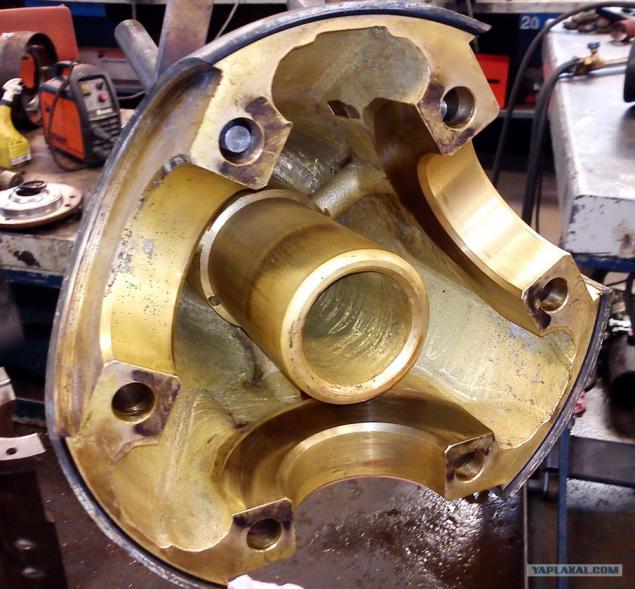

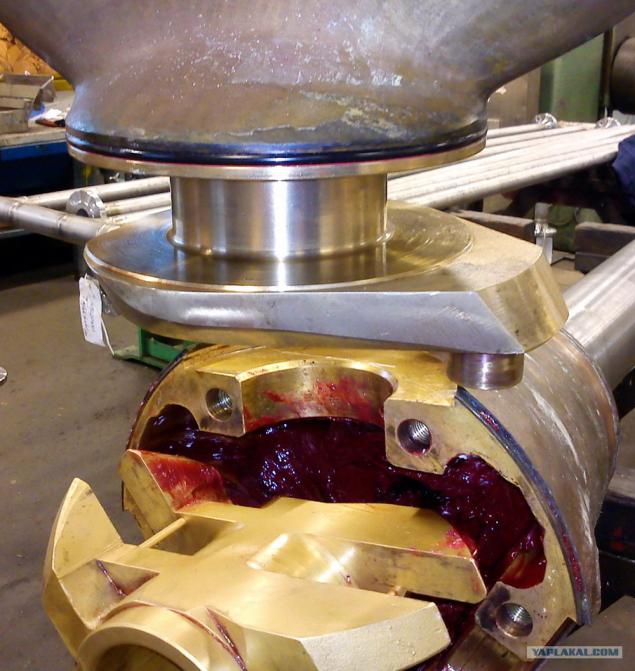

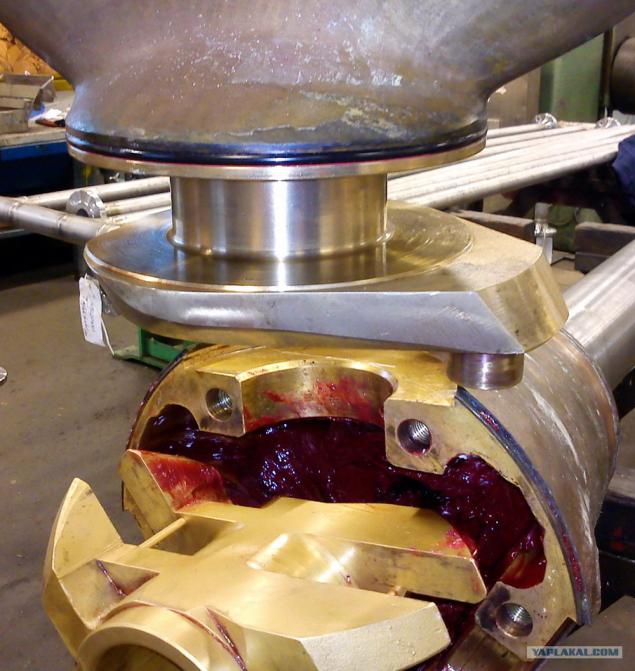

screw itself consists of a body, which has a cylindrical Rout the grooves to hold the blade. (Visible in synthetic lubricant)

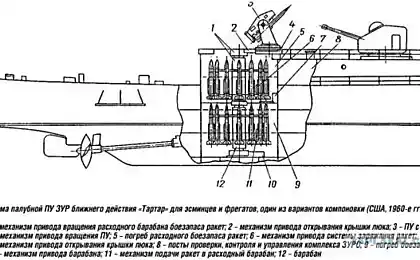

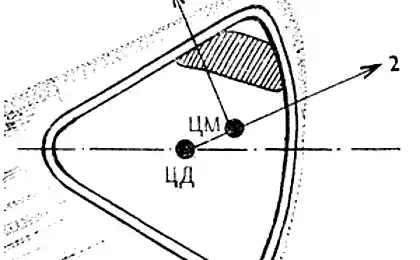

Inside the case is because the so-called heart of the screws. (I do not know how it is in Russian, but in a foreign language it is translated as the heart)

it has a bit of cunning form with three recesses for turning the blades ... it is fastened to the push rod, which in turn runs inside the shaft of the screw. On the transmission has a special device that pushes the bar and turns the blades thus

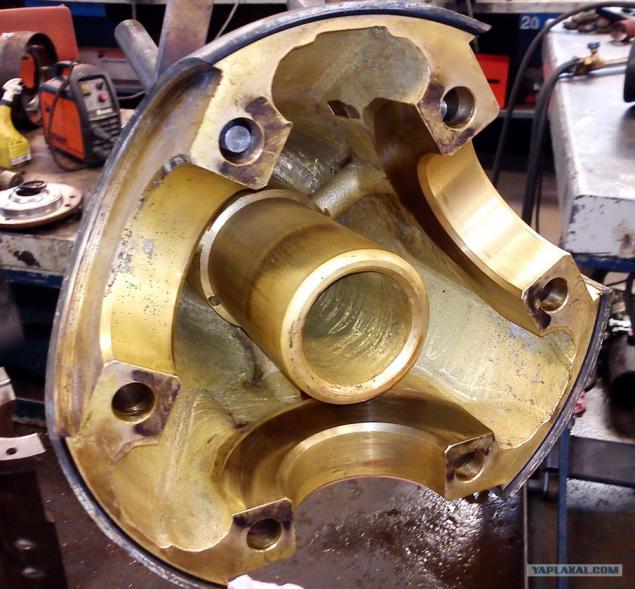

This case cover ... Inside view. The housing cover also has Cylindrical grooves that hold the blade.

Here is a blade ... and close the housing cover (view from the outside)

the blades of the clip is visible for lifting crane arms ... roll it hard ... She weighs one hundred kilograms under.

Generally, this screw is quite small ...

At the famous ship Costa Concordia size of 5-6 times longer.

the blades are inserted into the grooves of the screw body.

At the blade, as seen we have the same response bore. And also at the bottom of the blade has a pin on a leash (serving the lower part of the blade), on which sits a biscuit, and he in turn slides in a groove heart screw at a time when the blade is rotated on the leash ...

All this is made of brass.

this lower pin worn suhar- here is a form of his guileless ... Done it all kstati- brass.

crackers are numbered according to their blades.

for a more accurate representation - a view which shows a biscuit that is inserted onto the pin of the blade and it is in its groove in the center.

(Previously before assembly Grease)

the first two blades inserted sometimes difficult ... The whole structure is a bit like a puzzle type, when it is necessary at the same time get into the slots for the biscuits and to the cylindrical bore. With small size, everything is much easier. But if the parts are heavy and do not wear large (minimum clearances), then shove into place can be a little difficult ...

Well, finally a third blade in place ... you can probably have to close the lid until everything fell apart for heram and did not fall to her feet ...

after complete assembly you need to download the grease through a hose (visible on the very first pictures) ...

Pumped special high-pressure pump (pneumatic).

The head of the propeller swayed almost the whole bucket (about 18 kg)

Once the grease climbed from all the cracks propeller head, it is necessary to quickly turn off the supply.

Well, how would I have completed the topic.

Thank you for your patience and attention.

I apologize for not very good picture quality mobile phone.

Source:

(I envy the authors of these topics and a little sorry that fate has brought me to this technique)

I decided to post 12 pictures with his work about the ship's propeller.

He has the ability to change the angle of attack of the blades during rotation. (Probably like a helicopter propeller)

That's decided to show its components in order to become immediately clear principle of the unit changes the angle. If anyone is interested.

If you can- beforehand please do not break the topic.

in fact, the ship was under repair. Among the various works was supposed to make out, to fathom the gaps and then collect obratno.Tipa regulations.

Now the boat itself (from which the screw)

screw itself consists of a body, which has a cylindrical Rout the grooves to hold the blade. (Visible in synthetic lubricant)

Inside the case is because the so-called heart of the screws. (I do not know how it is in Russian, but in a foreign language it is translated as the heart)

it has a bit of cunning form with three recesses for turning the blades ... it is fastened to the push rod, which in turn runs inside the shaft of the screw. On the transmission has a special device that pushes the bar and turns the blades thus

This case cover ... Inside view. The housing cover also has Cylindrical grooves that hold the blade.

Here is a blade ... and close the housing cover (view from the outside)

the blades of the clip is visible for lifting crane arms ... roll it hard ... She weighs one hundred kilograms under.

Generally, this screw is quite small ...

At the famous ship Costa Concordia size of 5-6 times longer.

the blades are inserted into the grooves of the screw body.

At the blade, as seen we have the same response bore. And also at the bottom of the blade has a pin on a leash (serving the lower part of the blade), on which sits a biscuit, and he in turn slides in a groove heart screw at a time when the blade is rotated on the leash ...

All this is made of brass.

this lower pin worn suhar- here is a form of his guileless ... Done it all kstati- brass.

crackers are numbered according to their blades.

for a more accurate representation - a view which shows a biscuit that is inserted onto the pin of the blade and it is in its groove in the center.

(Previously before assembly Grease)

the first two blades inserted sometimes difficult ... The whole structure is a bit like a puzzle type, when it is necessary at the same time get into the slots for the biscuits and to the cylindrical bore. With small size, everything is much easier. But if the parts are heavy and do not wear large (minimum clearances), then shove into place can be a little difficult ...

Well, finally a third blade in place ... you can probably have to close the lid until everything fell apart for heram and did not fall to her feet ...

after complete assembly you need to download the grease through a hose (visible on the very first pictures) ...

Pumped special high-pressure pump (pneumatic).

The head of the propeller swayed almost the whole bucket (about 18 kg)

Once the grease climbed from all the cracks propeller head, it is necessary to quickly turn off the supply.

Well, how would I have completed the topic.

Thank you for your patience and attention.

I apologize for not very good picture quality mobile phone.

Source: