727

SVD of construction waste

Good afternoon! Yesterday I finally finished the layout of all your favorite rifle SVD. I decided to collect the layout of what is, that is, without buying anything special. Therefore, 100% up to recreate, alas, did not happen. Pokapatsya in his overfeed, I found a few wooden beams, some boards of dubious origin, old metal curtains which long ago hung curtains, steel pipe, the remains of the ventilation duct, well, a bunch of all sorts of different parts and unknown objects, boltikov- gaechek that I have several years of attempts to guard the couple and throw all this free stuff on the balcony)

It will be about 100 photos, when I finish, I'll let you know, please do not break)

Let's start

I started from the trunk. I decided it is made from curtains

2)

Details for flies - Aluminum + small piece of the segment curtains. Dremel cut out.

4)

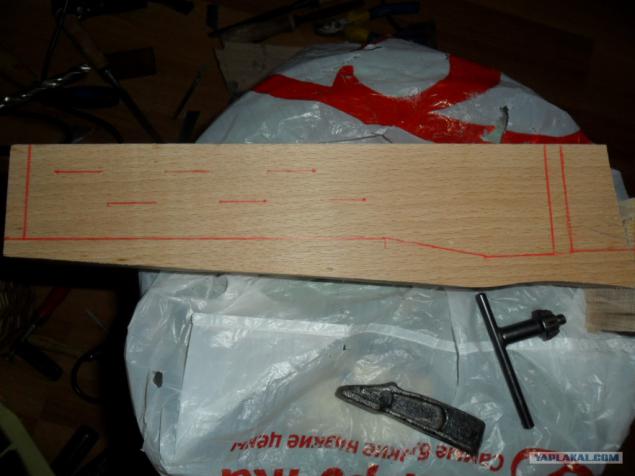

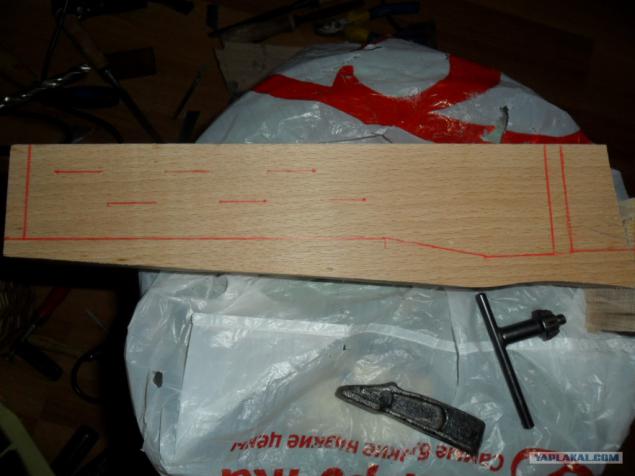

Make forearm. Be marked on the bar of beech

Glue drill, to cut the side contours

2)

Cut jigsaw of markup (do not forget to leave the allowance for processing). All drill holes

Nazhdachkoy plane and arrive at the desired shape, drill a hole for inserting the stem in the forearm)

It looks like that around the forearm after the first treatment

combine with the barrel

Well, something like this should all look)

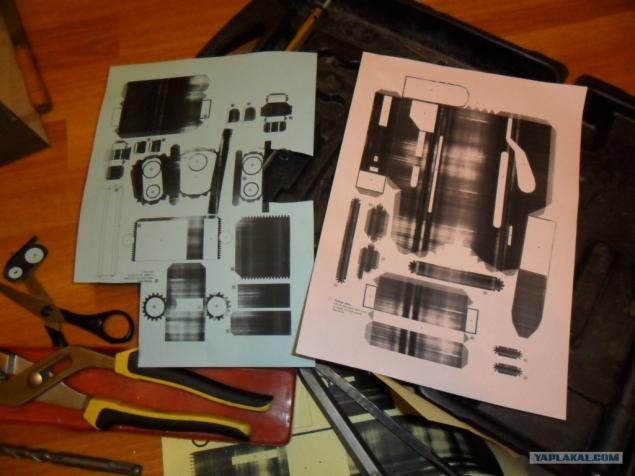

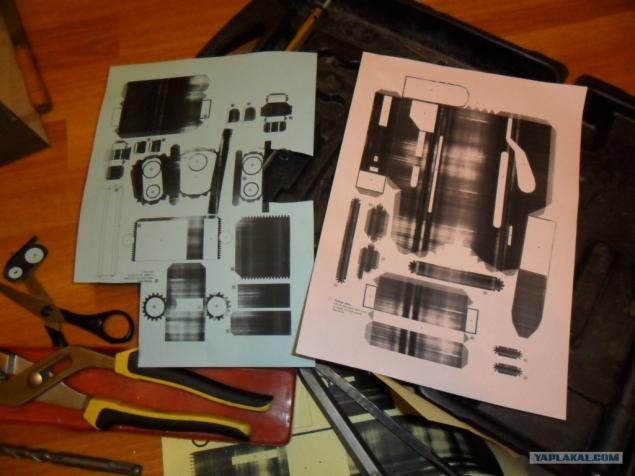

Tin ventilation do cover receiver

To do this, take the scan printed and glued on a piece of tin.

2)

Metal scissors carefully cut the contours of a future cover

Bends centrally along the cover. To be more exact, when I used the bending of the steel pipe, which is useful to us later)

Then take a Dremel ...

And neatly cut through what we need.

Now the manufacture of the bolt. As I said above, for folding the cover, I used a steel pipe. From this pipe, I cut a piece ...

I sawed it along, and a folded edge.

I take the old door handle

Bending it as desired, and fasten to the next slide frame

We get something like this)

2)

Spring to the gate could juggle. Guide to spring is not writhing and stopper, was to palm springs.

Now we produce shop. By the same principle as before - sweep on tin, tin snips - and more!

2)

Sticking poksipolom everything should be skleino.

add a few inside the store that's just such brackets (for strength)

2)

size such that it is necessary ...

Cold welding ribs do as the original product. Processed.

And color. All pro shop forgotten.

Now the task is, how do we reconcile all this. To do this, take sanitary bolt

Straight with nuts and area gently but firmly hammered it into the steel pipe.

And fixed to tsevyu in this way

2)

In order to make it clear why all this - this photo of the pre-assembly)

Now butt. Butt I made of pine planks 12mm thick. Frankly - a pine tree I do not like, because the material - it is shit. Beech though capricious and difficult to handle, but to work with him at times pleasant.

But in the absence of anything else - we do pine!

glue the two halves

they put the old battery ...

and on the battery pancakes from dumbbells and something else heavier

A day shoot, we treat, try on ...

and soaked in linseed oil to mix with a small amount of mining

That's one of the photos in the collection in the early stages of manufacturing))

Of this handful of useless, little-known objects we do mount an optical sight.

That's what we get as a result. Here I want to apologize - I was very fascinated by the process and forgot to take a picture. I'll tell you briefly what's left overs.

There were all sorts of flags are made, the guide, and make an "cosmetics" rifle - ribs on the cover. Also produced and bolted bottom rifle trigger, a safety clamp ...

2 side-

Latch store. It was from the old stepplera.

2)

the lower part of the rifle - magazine location.

Rib. In her letters to tip the scale

2)

already finished, complete.

at its future location)

Once again, everything is processed and begin basic impregnation of wood. I have already said that I use for impregnating linseed oil. This is the main component. He tends to polymerize with time - that is, tree in 2-3 years will be strong as a rock. Plus water-repellent properties. As I add linseed oil used motor oil, thus getting a reddish tint.

Generously butter put on the forearm and zamatyvaem film.

also, most do with the butt. The procedure is repeated 3-4 times. If the tree is dry - it absorbs the oil be healthy. Literally every 5-6 hours of wood is almost dry

Then wipe the rifle alcohol, and then again with alcohol, then with acetone, closing the masking tape all the wooden parts, and paint.

And that's what we get in the end. The sight I decided to put my old.

3)

4)

5)

The gate, as I wanted to cringe and klatsat ...

Shop unfastened)

And one more close-up.

this I have everything.

for the manufacture of rifles took nearly two months of work on the weekends ...

in the process it has been drilled left hand between the thumb and index finger. Broken one gripe, as China was by shit, snapped one bit, and I was going to hate the neighbors below)

Source:

It will be about 100 photos, when I finish, I'll let you know, please do not break)

Let's start

I started from the trunk. I decided it is made from curtains

2)

Details for flies - Aluminum + small piece of the segment curtains. Dremel cut out.

4)

Make forearm. Be marked on the bar of beech

Glue drill, to cut the side contours

2)

Cut jigsaw of markup (do not forget to leave the allowance for processing). All drill holes

Nazhdachkoy plane and arrive at the desired shape, drill a hole for inserting the stem in the forearm)

It looks like that around the forearm after the first treatment

combine with the barrel

Well, something like this should all look)

Tin ventilation do cover receiver

To do this, take the scan printed and glued on a piece of tin.

2)

Metal scissors carefully cut the contours of a future cover

Bends centrally along the cover. To be more exact, when I used the bending of the steel pipe, which is useful to us later)

Then take a Dremel ...

And neatly cut through what we need.

Now the manufacture of the bolt. As I said above, for folding the cover, I used a steel pipe. From this pipe, I cut a piece ...

I sawed it along, and a folded edge.

I take the old door handle

Bending it as desired, and fasten to the next slide frame

We get something like this)

2)

Spring to the gate could juggle. Guide to spring is not writhing and stopper, was to palm springs.

Now we produce shop. By the same principle as before - sweep on tin, tin snips - and more!

2)

Sticking poksipolom everything should be skleino.

add a few inside the store that's just such brackets (for strength)

2)

size such that it is necessary ...

Cold welding ribs do as the original product. Processed.

And color. All pro shop forgotten.

Now the task is, how do we reconcile all this. To do this, take sanitary bolt

Straight with nuts and area gently but firmly hammered it into the steel pipe.

And fixed to tsevyu in this way

2)

In order to make it clear why all this - this photo of the pre-assembly)

Now butt. Butt I made of pine planks 12mm thick. Frankly - a pine tree I do not like, because the material - it is shit. Beech though capricious and difficult to handle, but to work with him at times pleasant.

But in the absence of anything else - we do pine!

glue the two halves

they put the old battery ...

and on the battery pancakes from dumbbells and something else heavier

A day shoot, we treat, try on ...

and soaked in linseed oil to mix with a small amount of mining

That's one of the photos in the collection in the early stages of manufacturing))

Of this handful of useless, little-known objects we do mount an optical sight.

That's what we get as a result. Here I want to apologize - I was very fascinated by the process and forgot to take a picture. I'll tell you briefly what's left overs.

There were all sorts of flags are made, the guide, and make an "cosmetics" rifle - ribs on the cover. Also produced and bolted bottom rifle trigger, a safety clamp ...

2 side-

Latch store. It was from the old stepplera.

2)

the lower part of the rifle - magazine location.

Rib. In her letters to tip the scale

2)

already finished, complete.

at its future location)

Once again, everything is processed and begin basic impregnation of wood. I have already said that I use for impregnating linseed oil. This is the main component. He tends to polymerize with time - that is, tree in 2-3 years will be strong as a rock. Plus water-repellent properties. As I add linseed oil used motor oil, thus getting a reddish tint.

Generously butter put on the forearm and zamatyvaem film.

also, most do with the butt. The procedure is repeated 3-4 times. If the tree is dry - it absorbs the oil be healthy. Literally every 5-6 hours of wood is almost dry

Then wipe the rifle alcohol, and then again with alcohol, then with acetone, closing the masking tape all the wooden parts, and paint.

And that's what we get in the end. The sight I decided to put my old.

3)

4)

5)

The gate, as I wanted to cringe and klatsat ...

Shop unfastened)

And one more close-up.

this I have everything.

for the manufacture of rifles took nearly two months of work on the weekends ...

in the process it has been drilled left hand between the thumb and index finger. Broken one gripe, as China was by shit, snapped one bit, and I was going to hate the neighbors below)

Source: