604

Incredible technology - Arthur Kay will heat the coffee waste 15 000 houses of London!

As you know, daily morning Cup of coffee is not only palatable refreshing drink, but a few grams of waste that we did not hesitate to be sent to the destination.

“... And on purpose?” – once asked the founder of Bio-bean, and, on reflection, found coffee grounds to better use.

The idea to use recycled coffee grounds as an energy source for vehicles is not new. For example, several small power plants running on waste coffee pulp is the company "Kraft_Foods".

However, attempts to implement effective modern production complex, is able to regularly process large amounts of such waste to date has encountered a number of problems. Needed fresh ideas and these ideas could offer Arthur Kay (Arthur Kay) is the founder and ideological inspirer of the project Bio-bean.

The idea of creating a company and the same name of the project Bio-bean is ripe in a light head 23-year-old Arthur during the preparation of University curricula on the theme of sustainable closed-loop system for processing waste into energy for energy supply of residential and industrial buildings. And at the stage of a startup Bio-bean has managed to enlist the support of influential representatives of the London elite, including the mayor of London Boris Johnson.

Arthur Kay

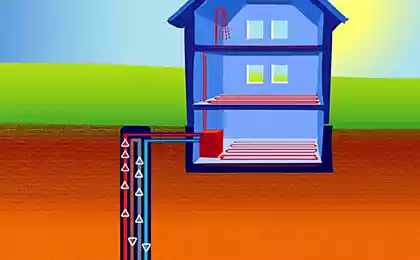

In the framework of the project Bio-bean Kay was able to offer its own high-performance processing, allowing the use of coffee pulp as a raw material for the production of environmentally friendly biodiesel fuel for transportation and granular composite for the heating of buildings.

12 Sep 2014 in the framework of the lottery Green Challenge for a start-up Bio-bean, Arthur Kay was awarded first prize in the amount of € 500,000 (US ~ $ 646 000), which allowed us to start implementing the project on a practical level.

Bio-bean today

Project Arthur Kay develops dynamically increasing production and extending the sphere of presence to the still emptying the market. Based all over London waste are dried on the area 1860 sq. m. the Oil contained in coffee pulp in concentration up to 20% is allocated from its structure in the process of biochemical extraction involving hexane. The solvent used in the extraction process when the cycle is completed almost fully can be reused. About 80% of the total weight of the waste remaining after passing through the stages of drying and extraction, are pelletized on the baling equipment. According to the company, the number of calories produced by burning coffee granules Bio-bean in the boiler is 1.5 times higher than that isolated burning sawdust.

One of the conditions for the successful functioning of the complete production cycle of Bio-bean smooth and flawless logistics. Business contacts in the highest circles of London allowed enterprising entrepreneurs in the short term to create an extensive network of suppliers, large industrial enterprises, exhibition and shopping centers, offices of leading companies, seven major railway stations London, not to mention coffee shops and other alternative sources of waste. The pulp is extracted from coffee machines and transferred employees Bio-bean totally free, is filled into bags and delivered to the company's production in real time.

Today, the production of Bio-bean has operational capacity for processing 50,000 tons of waste annually. Weekly volume of collected waste at this stage is limited to a few hundreds of tons. But based on the pace of development and the estimated data, already in 2016 the company will be able to process up to 50,000 tons (more than 1040 tonnes per week), i.e. to fully load the existing production capacity. And even at these production volumes the figure is only a quarter of the total regularly produced by the inhabitants of London coffee pulp.

It is planned to expand and power involved in the production of biofuels for the supply of urban transport infrastructure and, first and foremost, buses running on biodiesel.

The advantages offered by advanced technology, look quite convincing. Coffee waste as a feedstock for biofuel production, are not considered as a competitor to the raw materials used by man in the food chain. The process of biodiesel production from coffee pulp does not involve costly filtration step, as in the case of using, for this purpose vegetable oil. Due to the disposal of thousands of tons of coffee waste is subjected to anaerobic fermentation at the city dumps of large cities will be able to significantly reduce the greenhouse gas emissions that the most positive impact on the environment.

The best technology is for the suppliers of raw materials, saving on the export of coffee pulp at the country of the landfill during the year, a very tidy sum. Finally, the necessary volume of production of raw materials will be available until until coffee is grown and not diminished the passion of people to this healthy and delicious drink.

At Bio-bean estimates that the annual volume coffee dregs to landfill in the UK amounts to an astronomical figure of 500 000 tonnes. Of these, about 200 000 tonnes is accounted for by London. The strategic goal of Bio-bean at this stage – the production of so many pellets, which is enough to heat 15 000 of the capital's homes. Well, move is where. And given the personal qualities of the head of the Bio-bean team, level of support and sponsors the project, and Arthur Kay, in all probability, simply destined to become global.published

P. S. And remember, only by changing their consumption — together we change the world! ©

Join us in Facebook , Vkontakte, Odnoklassniki

Source: geektimes.ru/company/icover/blog/263844/

“... And on purpose?” – once asked the founder of Bio-bean, and, on reflection, found coffee grounds to better use.

The idea to use recycled coffee grounds as an energy source for vehicles is not new. For example, several small power plants running on waste coffee pulp is the company "Kraft_Foods".

However, attempts to implement effective modern production complex, is able to regularly process large amounts of such waste to date has encountered a number of problems. Needed fresh ideas and these ideas could offer Arthur Kay (Arthur Kay) is the founder and ideological inspirer of the project Bio-bean.

The idea of creating a company and the same name of the project Bio-bean is ripe in a light head 23-year-old Arthur during the preparation of University curricula on the theme of sustainable closed-loop system for processing waste into energy for energy supply of residential and industrial buildings. And at the stage of a startup Bio-bean has managed to enlist the support of influential representatives of the London elite, including the mayor of London Boris Johnson.

Arthur Kay

In the framework of the project Bio-bean Kay was able to offer its own high-performance processing, allowing the use of coffee pulp as a raw material for the production of environmentally friendly biodiesel fuel for transportation and granular composite for the heating of buildings.

12 Sep 2014 in the framework of the lottery Green Challenge for a start-up Bio-bean, Arthur Kay was awarded first prize in the amount of € 500,000 (US ~ $ 646 000), which allowed us to start implementing the project on a practical level.

Bio-bean today

Project Arthur Kay develops dynamically increasing production and extending the sphere of presence to the still emptying the market. Based all over London waste are dried on the area 1860 sq. m. the Oil contained in coffee pulp in concentration up to 20% is allocated from its structure in the process of biochemical extraction involving hexane. The solvent used in the extraction process when the cycle is completed almost fully can be reused. About 80% of the total weight of the waste remaining after passing through the stages of drying and extraction, are pelletized on the baling equipment. According to the company, the number of calories produced by burning coffee granules Bio-bean in the boiler is 1.5 times higher than that isolated burning sawdust.

One of the conditions for the successful functioning of the complete production cycle of Bio-bean smooth and flawless logistics. Business contacts in the highest circles of London allowed enterprising entrepreneurs in the short term to create an extensive network of suppliers, large industrial enterprises, exhibition and shopping centers, offices of leading companies, seven major railway stations London, not to mention coffee shops and other alternative sources of waste. The pulp is extracted from coffee machines and transferred employees Bio-bean totally free, is filled into bags and delivered to the company's production in real time.

Today, the production of Bio-bean has operational capacity for processing 50,000 tons of waste annually. Weekly volume of collected waste at this stage is limited to a few hundreds of tons. But based on the pace of development and the estimated data, already in 2016 the company will be able to process up to 50,000 tons (more than 1040 tonnes per week), i.e. to fully load the existing production capacity. And even at these production volumes the figure is only a quarter of the total regularly produced by the inhabitants of London coffee pulp.

It is planned to expand and power involved in the production of biofuels for the supply of urban transport infrastructure and, first and foremost, buses running on biodiesel.

The advantages offered by advanced technology, look quite convincing. Coffee waste as a feedstock for biofuel production, are not considered as a competitor to the raw materials used by man in the food chain. The process of biodiesel production from coffee pulp does not involve costly filtration step, as in the case of using, for this purpose vegetable oil. Due to the disposal of thousands of tons of coffee waste is subjected to anaerobic fermentation at the city dumps of large cities will be able to significantly reduce the greenhouse gas emissions that the most positive impact on the environment.

The best technology is for the suppliers of raw materials, saving on the export of coffee pulp at the country of the landfill during the year, a very tidy sum. Finally, the necessary volume of production of raw materials will be available until until coffee is grown and not diminished the passion of people to this healthy and delicious drink.

At Bio-bean estimates that the annual volume coffee dregs to landfill in the UK amounts to an astronomical figure of 500 000 tonnes. Of these, about 200 000 tonnes is accounted for by London. The strategic goal of Bio-bean at this stage – the production of so many pellets, which is enough to heat 15 000 of the capital's homes. Well, move is where. And given the personal qualities of the head of the Bio-bean team, level of support and sponsors the project, and Arthur Kay, in all probability, simply destined to become global.published

P. S. And remember, only by changing their consumption — together we change the world! ©

Join us in Facebook , Vkontakte, Odnoklassniki

Source: geektimes.ru/company/icover/blog/263844/