771

Heavy Forging Plant

On the last Sunday of September in the town of Zhodino, is celebrated Day of the Machine engineer, who is also the same day the city. On this day, two of the largest enterprises in the city held an open day. Naturally most of the visitors goes to BelAZ, forgetting about the Forge Plant, but in vain.

Author: fisher-y.livejournal.com/

2.Zavod entered service December 25, 1981, when it was put into operation the shop of wheels intended for the production of 11, 5 thousand tons of rims for cars "BelAZ". Today the company specializes in the manufacture of forgings and stampings from rolled, forging on crank and hot stamping presses, forging hammers, hammers forging followed by heat treatment and purification, as well as in the manufacture of rails, the rear axle housing, front axle beams, rims family BelAZ and MAZ trucks

3.Nachnёm our tour with a blacksmith shop

4.Nesmotrya the fact that the shop is pretty cool, the heat from the oven, simply monstrous. There is even a furnace installed water barrier. Also in the shop, near furnaces bathtubs with water in case of fire clothing

5. In the furnace loading ingot billet

6.Tam they heat

7.And sent to the forging of a 5-ton hammer

8.

9.Prosleduem to the site forging

10.Pech. Here, 286 pound preform is heated to a temperature of 1200 degrees

11.Zadvizhka opens

12.And on to roll out the red-hot billet

13.

14. And with a special hoist transferred under the hammer

15.Tsilindricheskuyu preform collapsed and then placed on a support with a cavity in the middle. Let me remind you, workpiece weight 286 kg, and at 1200

16.I knockouts

17.Poluchaetsya is such a toroidal blank

18.

19.Masshtab plant impresses

20.

21.Uchastok production disk rim

22.

23. We leave the termichku. By the way, pay attention, tiled metal plates

24.Uchastok heat treatment. To bring metals and their alloys properties of elasticity, ductility, strength increasing use different methods of heat treatment, such as thermo-mechanical processing and chemical-thermal method.

In order to prepare products for further processing steps in a so-called pre-processing type - a joke, that is, heating and maintenance of the product at high temperature, followed by gradual cooling to increase the plasticity of the material.

25.

26.Tut takes the heat treatment of forgings

27.

28. Firing.

29. The oven door is opened, and another batch of blank leaves in the oven

30.Ne I thought that such units anywhere else there

31.Vernёmsya in the blacksmith shop. It Presses 6300 tonnes

32.

33.A is a machine for plasma cutting

34.Idёm further and get to the shop, where the perforation spars

35.Vot original state spars

36.A it after perforation

37.A here is the dyroprobivochny complex firm Soenen

38.

39.

40.

41.Pereydёm the housing service shops

42.Zdes are repair-mechanical, mechanical stamping, machine assembly plant, a power building and other auxiliary production facilities.

43.Pila, is not it impressive

44.

45.A's results sawing

46.Metallicheskaya chips lovely.

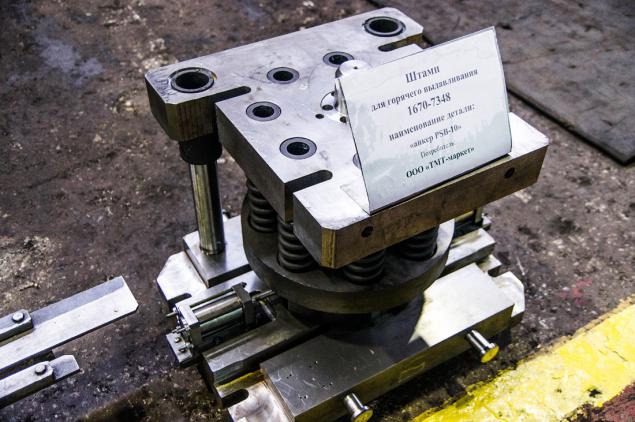

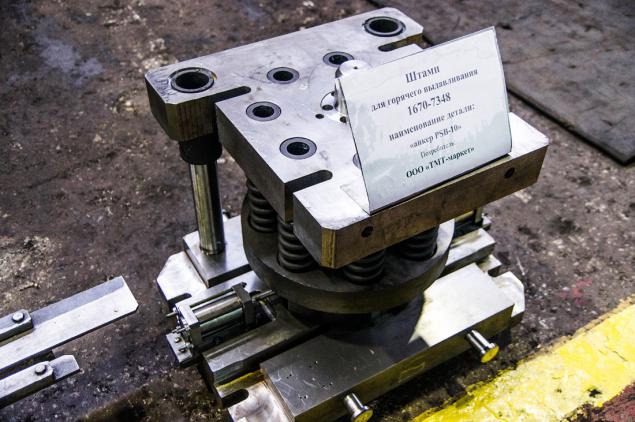

47.Shtampy hammers

48.

49.

50.

51.

52.A this is one of the final products of the production, the rear axle

That's all. Thanks to all.

Source:

Author: fisher-y.livejournal.com/

2.Zavod entered service December 25, 1981, when it was put into operation the shop of wheels intended for the production of 11, 5 thousand tons of rims for cars "BelAZ". Today the company specializes in the manufacture of forgings and stampings from rolled, forging on crank and hot stamping presses, forging hammers, hammers forging followed by heat treatment and purification, as well as in the manufacture of rails, the rear axle housing, front axle beams, rims family BelAZ and MAZ trucks

3.Nachnёm our tour with a blacksmith shop

4.Nesmotrya the fact that the shop is pretty cool, the heat from the oven, simply monstrous. There is even a furnace installed water barrier. Also in the shop, near furnaces bathtubs with water in case of fire clothing

5. In the furnace loading ingot billet

6.Tam they heat

7.And sent to the forging of a 5-ton hammer

8.

9.Prosleduem to the site forging

10.Pech. Here, 286 pound preform is heated to a temperature of 1200 degrees

11.Zadvizhka opens

12.And on to roll out the red-hot billet

13.

14. And with a special hoist transferred under the hammer

15.Tsilindricheskuyu preform collapsed and then placed on a support with a cavity in the middle. Let me remind you, workpiece weight 286 kg, and at 1200

16.I knockouts

17.Poluchaetsya is such a toroidal blank

18.

19.Masshtab plant impresses

20.

21.Uchastok production disk rim

22.

23. We leave the termichku. By the way, pay attention, tiled metal plates

24.Uchastok heat treatment. To bring metals and their alloys properties of elasticity, ductility, strength increasing use different methods of heat treatment, such as thermo-mechanical processing and chemical-thermal method.

In order to prepare products for further processing steps in a so-called pre-processing type - a joke, that is, heating and maintenance of the product at high temperature, followed by gradual cooling to increase the plasticity of the material.

25.

26.Tut takes the heat treatment of forgings

27.

28. Firing.

29. The oven door is opened, and another batch of blank leaves in the oven

30.Ne I thought that such units anywhere else there

31.Vernёmsya in the blacksmith shop. It Presses 6300 tonnes

32.

33.A is a machine for plasma cutting

34.Idёm further and get to the shop, where the perforation spars

35.Vot original state spars

36.A it after perforation

37.A here is the dyroprobivochny complex firm Soenen

38.

39.

40.

41.Pereydёm the housing service shops

42.Zdes are repair-mechanical, mechanical stamping, machine assembly plant, a power building and other auxiliary production facilities.

43.Pila, is not it impressive

44.

45.A's results sawing

46.Metallicheskaya chips lovely.

47.Shtampy hammers

48.

49.

50.

51.

52.A this is one of the final products of the production, the rear axle

That's all. Thanks to all.

Source: