774

Manufacture of the stove for melting metal

This picture is to attract attention.

Then follow chilling images and text on the establishment of the crematorium portable 'Squirrel' on the plot to create happiness for all of you and to silence, and the rest of the sea.

24 photo.

Author Emilio

In the beginning was the word ...

And slide the cover loam, bush had grown according to plan, the knife and shovel.

In the future (unless of course it is) should be approached more consciously to the construction of the stove.

Only here's the problem:

As long as you build-not know how to, there is no experience yet, but bare theory. And how ready, because you know that everything necessary was different from the beginning to do.

In general - the bottom of the hole blower, above the camera combustion hole for wood and coal for vёmki / recesses all (just above it is necessary to have a camera for combustion was like a trough at the bottom, but on this later), and then a wooden frame, which is then burned. Ideally, it is necessary to weave a thread of willow and often, often, larger-volume and more ... At the top of the hole for the pipe wider ...

The floor of the chamber hole visible ash - later there all fucking crumble, as I did them ryhlyake. Perhaps it makes sense to mix the bricks and are spread, and here the soil is already formed - all pellets and organic. Loose or molded, and it is necessary to destroy lepilos pellets and all peremyat.

And so leisurely and clung svezhenaklannym ...

Adowa protopka.

Evaporating moisture from the walls looks infernal.

Immediately reminded of orcs Sarumyanskie.

Slightly dried up and podkoptit.

Day Two.

Hosts area took pity on me and gave a piece of pipe, which I did not fall to the wind - strapped to the three twigs.

There is a loose soil lining for thermal insulation (longer keep warm), a hole for firewood moved by 15-20 centimeters above. I had to gently break the wall, remove the unburned bars and old zaleplivat.

Also presented a piece of 18x18 cm steel plate 3mm thick with holes centimeter in diameter - the type of grill to coals failed.

The stove in the glory of all of us there was a resonance chamber size, pipe length and capacity purged age, causing it came out in pulsating mode flashes at intervals of about 0, 8 seconds.

That is, the flame disappeared altogether, and then it all flashed, that already took off from the pipe.

Who wants Googling on the subject - poke "pulse jet engine».

Left branch stuck then to stick a thermocouple, but even so then stuck through the entrance.

On the third day I Choate scored on the stove and "made type" "type crucible».

From nemednoy wire mesh stakanets bungled the loop and tried to stick round Jurassic loam to silty sand with Art. Metro Kantemirovskaya but get complete crap.

Day four, the final.

To heighten the Hell and Satanism - that I kidanul to bark.

In fact, almost no smoke at all.

It is I "type crucible" thrust "type of shape" with a wax model.

I buy special wax for modeling - it is hard, light and melts at 100-plus. What's really behind the composition - xs. Half a kilo of 500r. is about.

Molds were made of covering loam from the place where I hovered in the construction of the furnace. That night was freezing. I had a flashlight at night without worry unprotected handle a stern and gentle sadness loam.

Just stupid clung stencil, passed and put in the oven to dry in the house, all the morning dried up and the wax poplavilsya.

On top of the stencil - a channel for casting and metal funnel.

Eto 'type crucible "taken out of the oven.

Judging by the smell - in Jurassic clay to fig organic sulfur in the form of all. I took a sip of smoke and coughed for a long time.

This picture makes me memories of the stars and nuclear fusion.

The result was a garbage hollow inside. I'm back to the old broken brass keys little tin-lead solder blurted. Inter was what happens. This results in a dull silver alloy fills only the walls and very fragile.

This stick has a form of the second stencil, without crucibles. Tupou wire wrapped shape and yeah.

Measure the temperature with a thermometer for thermocouples (chromel-alumel yuzal). The thermometer was so in 2005, was bought in the store Chip & Dip for my aspirantstva and I am honestly Gaugeable temperature gradients in elektropechkah for autoclaves. Since then he is at work with nothing to do.

And since life is short and everything is gone, and the subject is probably also want to use it for the purpose for which it was intended. So I took it a little drive. I'm good, I will return ...

This thermometer to 700 degrees shows up to to 0, n degrees, then just degrees, ten minutes. You can buy a program, provodocheg and display the temperature on the PC in the form of graphs and attach another thermocouple.

Can juzat thermocouple other copper-based alloys, some, such as platinum-rhodium impossible.

Chromel alumel and melted at 1200 somewhere, but because they are studded in brass, in the moment of its melting thermocouple corroded and also melted. So as soon as the temperature starts to ride - so it means and brass poplavilas heh heh.

The next time will be in the form of clay, and deepening to do to thrust the thermocouple to not contacted with nothing.

The furnace idle in itself, with birch charcoal from the bag from the supermarket raskochegarivaetsya up to 900 degrees Celsius.

I'm using the burner nozzles on gas cylinder - brought the temperature up to a thousand with a little. The scoreboard was captured just the moment when the 666 contrary.

In the future, it is necessary to fan and to bring down the pipe, then must itself for a thousand skaknut.

We remove asbestos compressed or slate, or is it the same thing - xs.

Harvesting in general, and there is some.

Loam is clearly obzhёgsya to partial melting and became prevraschatsya in earthenware coca something.

Again clapped flashbacks of how few times I was a star, and I went into any fusion of heavy elements.

A good time was!

Those atoms that are in me, and now is in you heh heh ...

Beauty - terrible force!

Incidentally loam on drying hardly cracked.

We must otmutit it in a blender, pour the clay component and prevent then from coarse sand and silty bypassing the fine fraction. Then do not be split.

By the way!

The cover of glacial loam - not fig sulfur is not present in an amount to stink and yellow plaque to form. By guglezhu happened that in the brass can be sulfur, arsenic, antimony and others. Her. at a concentration of 0%

2mass But it does not stink of garlic, namely sulfur ...

Zafigachit piece brass bomb probe, tomorrow is just a change in the robot tknu once there for interest.

I waved to them while it was hot, thereby portraying centrifugal casting, and then shoved all in the water.

And yet turned brass ritual toporeg!

Horseradish course, since I do not try to form for the manufacture of casting, but it was not the main task.

The main task was to make a working oven and after it turned out well.

Eeeeeeeee!

Even some patterns are visible and ribs.

...

...

To heap:

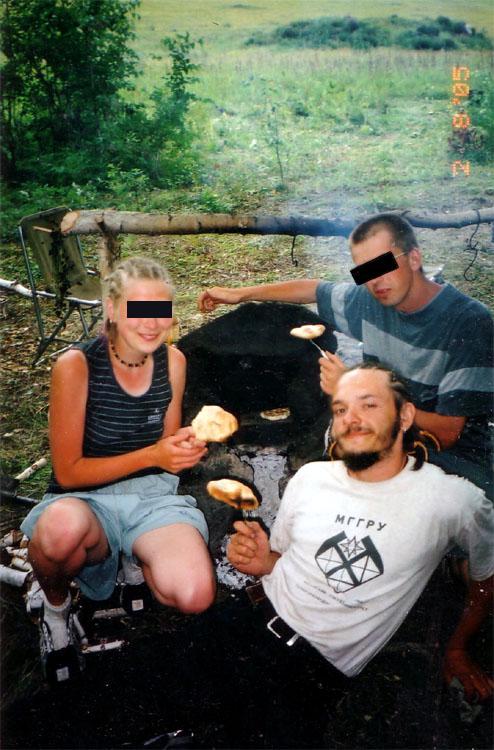

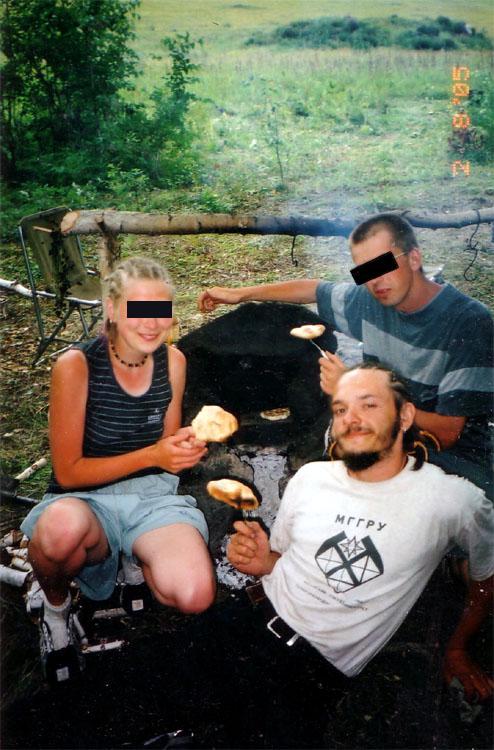

It is the second kiln made me a hell of grazing.

The first was made in 2005 in the Trans-Baikal region. We have a field was. Left to guard the camp and cook priduroshnyh.

I then dragged from the creek stones and stinking black mud of that. The whole day was building and burned, to gloss over the gap.

The result was a great oven cakes.

Soot on the rocks serves as a Teflon coating.

Raw dough clings to and kept, but then moved slightly and she finished otlipla.

Yeast makes the dough with poppy seeds on a sour milk, as I remember ...

And certainly I think everyone understands that all sorts of cakes from the oven - it korazdo kosher than those that are fried in a skillet or oven baked in the kitchen.

Who has the land - can make cakes for the stove for one weekend.

And if you have kids, you should show them this post (I'm here like no mater special) interest, give up a shovel and they build you all.

These are the pies ...

Source:

Then follow chilling images and text on the establishment of the crematorium portable 'Squirrel' on the plot to create happiness for all of you and to silence, and the rest of the sea.

24 photo.

Author Emilio

In the beginning was the word ...

And slide the cover loam, bush had grown according to plan, the knife and shovel.

In the future (unless of course it is) should be approached more consciously to the construction of the stove.

Only here's the problem:

As long as you build-not know how to, there is no experience yet, but bare theory. And how ready, because you know that everything necessary was different from the beginning to do.

In general - the bottom of the hole blower, above the camera combustion hole for wood and coal for vёmki / recesses all (just above it is necessary to have a camera for combustion was like a trough at the bottom, but on this later), and then a wooden frame, which is then burned. Ideally, it is necessary to weave a thread of willow and often, often, larger-volume and more ... At the top of the hole for the pipe wider ...

The floor of the chamber hole visible ash - later there all fucking crumble, as I did them ryhlyake. Perhaps it makes sense to mix the bricks and are spread, and here the soil is already formed - all pellets and organic. Loose or molded, and it is necessary to destroy lepilos pellets and all peremyat.

And so leisurely and clung svezhenaklannym ...

Adowa protopka.

Evaporating moisture from the walls looks infernal.

Immediately reminded of orcs Sarumyanskie.

Slightly dried up and podkoptit.

Day Two.

Hosts area took pity on me and gave a piece of pipe, which I did not fall to the wind - strapped to the three twigs.

There is a loose soil lining for thermal insulation (longer keep warm), a hole for firewood moved by 15-20 centimeters above. I had to gently break the wall, remove the unburned bars and old zaleplivat.

Also presented a piece of 18x18 cm steel plate 3mm thick with holes centimeter in diameter - the type of grill to coals failed.

The stove in the glory of all of us there was a resonance chamber size, pipe length and capacity purged age, causing it came out in pulsating mode flashes at intervals of about 0, 8 seconds.

That is, the flame disappeared altogether, and then it all flashed, that already took off from the pipe.

Who wants Googling on the subject - poke "pulse jet engine».

Left branch stuck then to stick a thermocouple, but even so then stuck through the entrance.

On the third day I Choate scored on the stove and "made type" "type crucible».

From nemednoy wire mesh stakanets bungled the loop and tried to stick round Jurassic loam to silty sand with Art. Metro Kantemirovskaya but get complete crap.

Day four, the final.

To heighten the Hell and Satanism - that I kidanul to bark.

In fact, almost no smoke at all.

It is I "type crucible" thrust "type of shape" with a wax model.

I buy special wax for modeling - it is hard, light and melts at 100-plus. What's really behind the composition - xs. Half a kilo of 500r. is about.

Molds were made of covering loam from the place where I hovered in the construction of the furnace. That night was freezing. I had a flashlight at night without worry unprotected handle a stern and gentle sadness loam.

Just stupid clung stencil, passed and put in the oven to dry in the house, all the morning dried up and the wax poplavilsya.

On top of the stencil - a channel for casting and metal funnel.

Eto 'type crucible "taken out of the oven.

Judging by the smell - in Jurassic clay to fig organic sulfur in the form of all. I took a sip of smoke and coughed for a long time.

This picture makes me memories of the stars and nuclear fusion.

The result was a garbage hollow inside. I'm back to the old broken brass keys little tin-lead solder blurted. Inter was what happens. This results in a dull silver alloy fills only the walls and very fragile.

This stick has a form of the second stencil, without crucibles. Tupou wire wrapped shape and yeah.

Measure the temperature with a thermometer for thermocouples (chromel-alumel yuzal). The thermometer was so in 2005, was bought in the store Chip & Dip for my aspirantstva and I am honestly Gaugeable temperature gradients in elektropechkah for autoclaves. Since then he is at work with nothing to do.

And since life is short and everything is gone, and the subject is probably also want to use it for the purpose for which it was intended. So I took it a little drive. I'm good, I will return ...

This thermometer to 700 degrees shows up to to 0, n degrees, then just degrees, ten minutes. You can buy a program, provodocheg and display the temperature on the PC in the form of graphs and attach another thermocouple.

Can juzat thermocouple other copper-based alloys, some, such as platinum-rhodium impossible.

Chromel alumel and melted at 1200 somewhere, but because they are studded in brass, in the moment of its melting thermocouple corroded and also melted. So as soon as the temperature starts to ride - so it means and brass poplavilas heh heh.

The next time will be in the form of clay, and deepening to do to thrust the thermocouple to not contacted with nothing.

The furnace idle in itself, with birch charcoal from the bag from the supermarket raskochegarivaetsya up to 900 degrees Celsius.

I'm using the burner nozzles on gas cylinder - brought the temperature up to a thousand with a little. The scoreboard was captured just the moment when the 666 contrary.

In the future, it is necessary to fan and to bring down the pipe, then must itself for a thousand skaknut.

We remove asbestos compressed or slate, or is it the same thing - xs.

Harvesting in general, and there is some.

Loam is clearly obzhёgsya to partial melting and became prevraschatsya in earthenware coca something.

Again clapped flashbacks of how few times I was a star, and I went into any fusion of heavy elements.

A good time was!

Those atoms that are in me, and now is in you heh heh ...

Beauty - terrible force!

Incidentally loam on drying hardly cracked.

We must otmutit it in a blender, pour the clay component and prevent then from coarse sand and silty bypassing the fine fraction. Then do not be split.

By the way!

The cover of glacial loam - not fig sulfur is not present in an amount to stink and yellow plaque to form. By guglezhu happened that in the brass can be sulfur, arsenic, antimony and others. Her. at a concentration of 0%

2mass But it does not stink of garlic, namely sulfur ...

Zafigachit piece brass bomb probe, tomorrow is just a change in the robot tknu once there for interest.

I waved to them while it was hot, thereby portraying centrifugal casting, and then shoved all in the water.

And yet turned brass ritual toporeg!

Horseradish course, since I do not try to form for the manufacture of casting, but it was not the main task.

The main task was to make a working oven and after it turned out well.

Eeeeeeeee!

Even some patterns are visible and ribs.

...

...

To heap:

It is the second kiln made me a hell of grazing.

The first was made in 2005 in the Trans-Baikal region. We have a field was. Left to guard the camp and cook priduroshnyh.

I then dragged from the creek stones and stinking black mud of that. The whole day was building and burned, to gloss over the gap.

The result was a great oven cakes.

Soot on the rocks serves as a Teflon coating.

Raw dough clings to and kept, but then moved slightly and she finished otlipla.

Yeast makes the dough with poppy seeds on a sour milk, as I remember ...

And certainly I think everyone understands that all sorts of cakes from the oven - it korazdo kosher than those that are fried in a skillet or oven baked in the kitchen.

Who has the land - can make cakes for the stove for one weekend.

And if you have kids, you should show them this post (I'm here like no mater special) interest, give up a shovel and they build you all.

These are the pies ...

Source: