1019

Belarusian smithy

In 2006, one of the students of Mogilev with a partner decided to take a very unusual kind of business - to open his own smithy. Under the cut picture story about how simple Smithy about 50 "squares" has turned into a successful company, whose customers include Moscow multimillionaires. And it all began with the purchase of the old equipment, which cost the boys 1,000 $

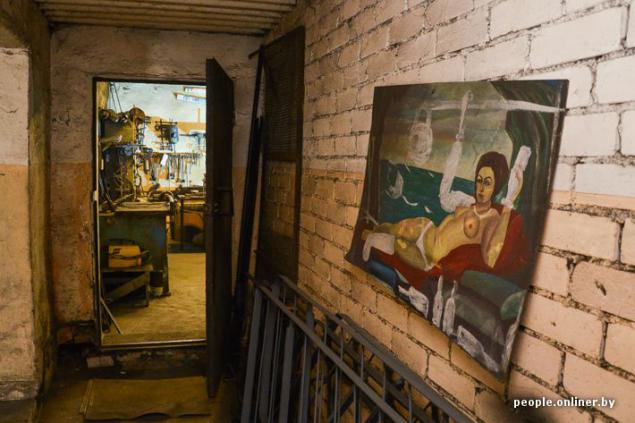

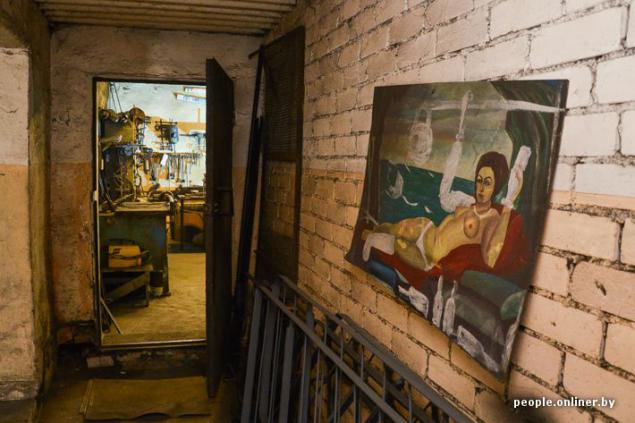

Former Mogilev regenerative plant, which is a smithy, you can make movies about World War II. Shattered shop, wry warehouses, devastation and mud - the scenery cause depression.

In the midst of this outrage - looks unpresentable building-hut. We are here.

Workers fill a bucket of coal, melt the horn. Burning fire, screams cutter banging hammers. Anton Mashtapa tells how it all began.

- Why Smithy? Metalworks - beautiful and richly rewarding business if properly deal with them - he says. - The basis - a heavy hard work of a blacksmith, so these things are expensive forged.

Why I start a business? Found in an old farm equipment, which had been written off. Redeem it. In those days it cost us about $ 1,000. That is much money is not needed. Get as SP, then, after the legislative changes in the company reformatted.

Not all, of course, it was smooth. Even if it's junk, which is rotting, no one needs, we need to issue hundreds of pieces of paper with the purchase. Yes, and try to estimate its market value. But we still managed not to overpay.

Then he began to search for specialists. We took a skilled master. In Mogilev there blacksmithing school, attracted graduates from there, where he taught. At first the guys performed a simple operation, and now, after 8 years, have themselves serious masters, teach young people. Contract and invited professionals from Russia, Ukraine, who shared their skills.

Initially working in a small room, about 50 "squares." Then he moved here. Conveniently, the production is located in the city - easy to get to. Yes, the building does not look much, but cozy inside. Now we have several teams: the art of forging, for the manufacture of products from simple metal brigade cleaning and painting. In total in the company of about 10 people.

But red hot horn to the desired temperature. One of blacksmiths tongs taking a metal workpiece, puts it into the fire. Next, the heated metal rods Pneumatic break. Cool, using a special form of relief is obtained (in this case the relief leaf roses), resorting to the manual hammer.

- Using a hammer and improvised devices of different shapes and pieces that we do ourselves, we knock on the anvil and arch elements of the final product - tell the guys. - And so the whole day. Hard Work? Try even two o'clock hammer wave! But it has to bend and "the cold».

In the forge of several rooms, halls, have an impromptu mini-gym. Without frills, no German and Chinese wallpaper sets, brutal. So after all the men engaged in a severe case ...

- No matter what you do: Interior, stairs or furniture. The work always begins with the preparation of the design project - Anton Mashtapa describes the main stages of production. - Our designer makes a 3D-visualization, coordinates the details with the customer. Then the blacksmith forges under his control all the elements. Collector welder combines them into a single composition. The product is transferred to the processing area where stripping occurs. Specialist removes weld defects, extra layers of metal. The next stage - priming, painting. And finally, when it comes, for example, on the stairs, we leave the site and perform the installation.

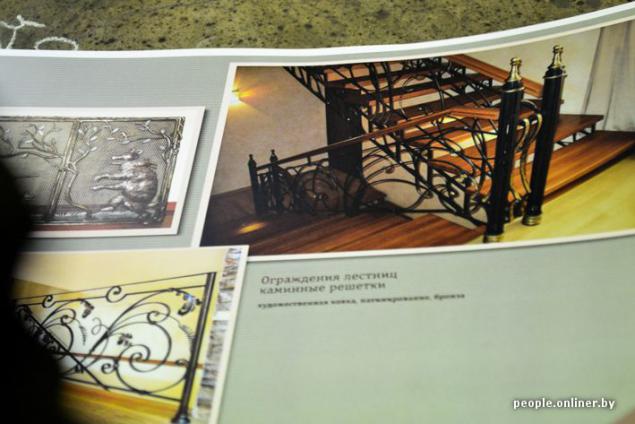

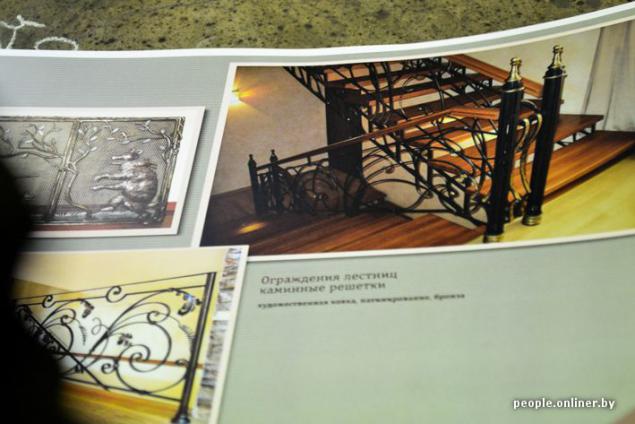

- We started with very simple things: benches, urns, which made for the city - continues the director of the company. - On the urn could earn about $ 50. Then, with increasing skill, began to make more sophisticated products. We entered the market and took part in international exhibitions. Earned reputation. There were orders in Minsk, Moscow. In the capital of Belarus carried out the order to the spiritual and educational center in the Nemiga. Make out the front group at Komsomolskaya Street. We now have a large government order for the Trinity suburb. There and arches, and wrought-iron clock. To win the tender, most of the work already completed, waiting for payment. What is interesting such orders, it's your volume. Let the government not prepared to pay the market price ... It's nice, however, that the historical things that we are doing for Minsk, beautify the city, will remain at 200-300 years.

The most expensive order? Probably staircase at around $ 1,300 per square meter. And it was just 10 meters of the stairs, but we have been about 4 months.

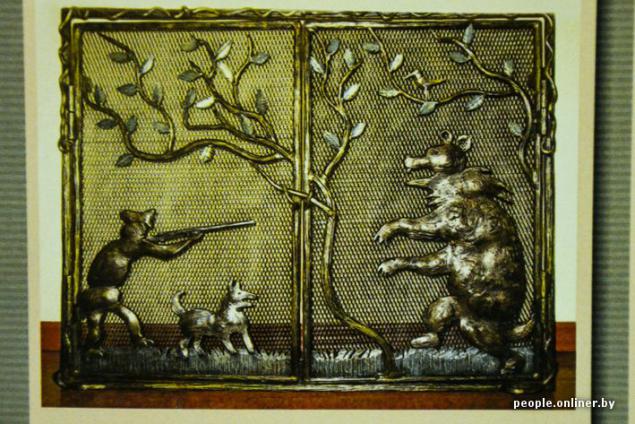

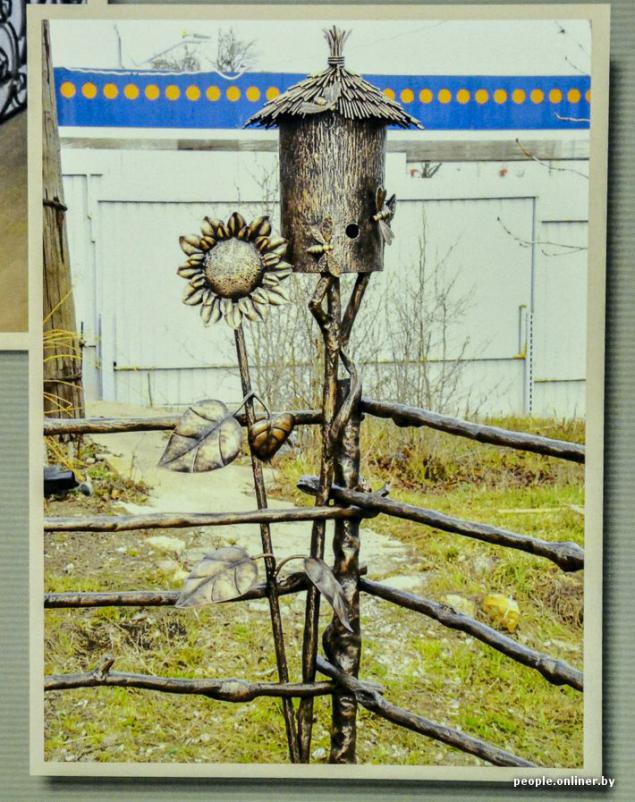

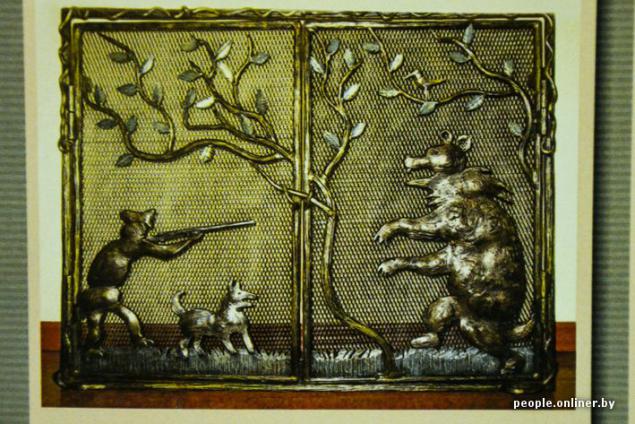

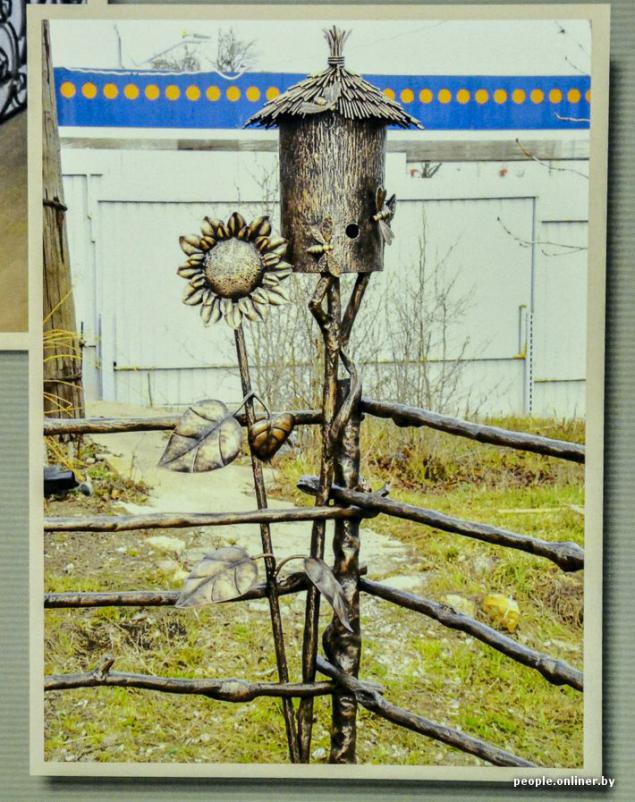

Forged and mirrors, and the mantel kits, and pinwheels, and fences on the balconies. One Moscow billionaire who, unfortunately, recently shot, made a hamlet called "Dikanka". There's all the style of old Ukrainian village. Manufactured for a fence in the form of a rod, forged a hive of metal, other interesting things. In principle, you can fulfill any wish of the customer.

- Now a very demanding client, - says Anton. - Interior items bought mostly wealthy people living in expensive houses. They travel the world, seen a lot, know what the quality. Therefore, can and capricious. Not to say that competition in the market is very strong, but it is. Some use welded elements and called this work of art forging, although in fact it is not. Hot forging, in which we specialize - it is always the author, an individual, a piece-work. Therefore, the more valued.

The rent per month spent about € 1000. Plus fee for communal electricity. Approximately 37-40% of the cost structure of the company, says Anton, take materials: metal, coal, coke. The remaining part - the salary to employees (it is $ 600-900, depending on the output, the number of orders), taxes.

- How profitable blacksmith business? Again, the correct approach is the moneymaker. Now we plan to invest in new equipment, buy hammers. We would like to open a shop near Minsk. That is to grow, - says the source of the plans.

- In a large SUV you have already earned themselves?

- The point is not in the jeep, and in the development, expansion of business - does not respond to the provocation of our director. - A jeep with me, by the way, was. But I had to sell to pay off people. There were questions on working with state delays payments. But all is not so bad. The difficulties can always be overcome. The main thing - do not be afraid to take risks.

Source: people.onliner.by

Former Mogilev regenerative plant, which is a smithy, you can make movies about World War II. Shattered shop, wry warehouses, devastation and mud - the scenery cause depression.

In the midst of this outrage - looks unpresentable building-hut. We are here.

Workers fill a bucket of coal, melt the horn. Burning fire, screams cutter banging hammers. Anton Mashtapa tells how it all began.

- Why Smithy? Metalworks - beautiful and richly rewarding business if properly deal with them - he says. - The basis - a heavy hard work of a blacksmith, so these things are expensive forged.

Why I start a business? Found in an old farm equipment, which had been written off. Redeem it. In those days it cost us about $ 1,000. That is much money is not needed. Get as SP, then, after the legislative changes in the company reformatted.

Not all, of course, it was smooth. Even if it's junk, which is rotting, no one needs, we need to issue hundreds of pieces of paper with the purchase. Yes, and try to estimate its market value. But we still managed not to overpay.

Then he began to search for specialists. We took a skilled master. In Mogilev there blacksmithing school, attracted graduates from there, where he taught. At first the guys performed a simple operation, and now, after 8 years, have themselves serious masters, teach young people. Contract and invited professionals from Russia, Ukraine, who shared their skills.

Initially working in a small room, about 50 "squares." Then he moved here. Conveniently, the production is located in the city - easy to get to. Yes, the building does not look much, but cozy inside. Now we have several teams: the art of forging, for the manufacture of products from simple metal brigade cleaning and painting. In total in the company of about 10 people.

But red hot horn to the desired temperature. One of blacksmiths tongs taking a metal workpiece, puts it into the fire. Next, the heated metal rods Pneumatic break. Cool, using a special form of relief is obtained (in this case the relief leaf roses), resorting to the manual hammer.

- Using a hammer and improvised devices of different shapes and pieces that we do ourselves, we knock on the anvil and arch elements of the final product - tell the guys. - And so the whole day. Hard Work? Try even two o'clock hammer wave! But it has to bend and "the cold».

In the forge of several rooms, halls, have an impromptu mini-gym. Without frills, no German and Chinese wallpaper sets, brutal. So after all the men engaged in a severe case ...

- No matter what you do: Interior, stairs or furniture. The work always begins with the preparation of the design project - Anton Mashtapa describes the main stages of production. - Our designer makes a 3D-visualization, coordinates the details with the customer. Then the blacksmith forges under his control all the elements. Collector welder combines them into a single composition. The product is transferred to the processing area where stripping occurs. Specialist removes weld defects, extra layers of metal. The next stage - priming, painting. And finally, when it comes, for example, on the stairs, we leave the site and perform the installation.

- We started with very simple things: benches, urns, which made for the city - continues the director of the company. - On the urn could earn about $ 50. Then, with increasing skill, began to make more sophisticated products. We entered the market and took part in international exhibitions. Earned reputation. There were orders in Minsk, Moscow. In the capital of Belarus carried out the order to the spiritual and educational center in the Nemiga. Make out the front group at Komsomolskaya Street. We now have a large government order for the Trinity suburb. There and arches, and wrought-iron clock. To win the tender, most of the work already completed, waiting for payment. What is interesting such orders, it's your volume. Let the government not prepared to pay the market price ... It's nice, however, that the historical things that we are doing for Minsk, beautify the city, will remain at 200-300 years.

The most expensive order? Probably staircase at around $ 1,300 per square meter. And it was just 10 meters of the stairs, but we have been about 4 months.

Forged and mirrors, and the mantel kits, and pinwheels, and fences on the balconies. One Moscow billionaire who, unfortunately, recently shot, made a hamlet called "Dikanka". There's all the style of old Ukrainian village. Manufactured for a fence in the form of a rod, forged a hive of metal, other interesting things. In principle, you can fulfill any wish of the customer.

- Now a very demanding client, - says Anton. - Interior items bought mostly wealthy people living in expensive houses. They travel the world, seen a lot, know what the quality. Therefore, can and capricious. Not to say that competition in the market is very strong, but it is. Some use welded elements and called this work of art forging, although in fact it is not. Hot forging, in which we specialize - it is always the author, an individual, a piece-work. Therefore, the more valued.

The rent per month spent about € 1000. Plus fee for communal electricity. Approximately 37-40% of the cost structure of the company, says Anton, take materials: metal, coal, coke. The remaining part - the salary to employees (it is $ 600-900, depending on the output, the number of orders), taxes.

- How profitable blacksmith business? Again, the correct approach is the moneymaker. Now we plan to invest in new equipment, buy hammers. We would like to open a shop near Minsk. That is to grow, - says the source of the plans.

- In a large SUV you have already earned themselves?

- The point is not in the jeep, and in the development, expansion of business - does not respond to the provocation of our director. - A jeep with me, by the way, was. But I had to sell to pay off people. There were questions on working with state delays payments. But all is not so bad. The difficulties can always be overcome. The main thing - do not be afraid to take risks.

Source: people.onliner.by