4649

Repair escalator in the metro (42 photos)

Offers a glimpse into the interior of the escalator and look at the time-consuming repair this moving stairs.

Everyone is familiar with this device, someone riding on it every day :)

From January 9 began overhaul escalator №3 Art. "Polytechnic Institute". Such repairs are carried out regularly at all stations, but "Polytech" opened in 1963 and having 3 escalator during repairs pops one annoying trait.

During normal operation, the station in the morning peak flow of people on the way out so that you have to use all three machines: two on the rise and one on the descent. Exactly the same situation in the neighboring "the Station", where the last repair escalators took only a couple of years ago. This means that if one of the escalators stopped for repairs, have to sacrifice something. Leave one escalator on the descent and ascent can not be one-on-one escalator will not be able to remove the entire flow from the bottom and the people will gradually accumulate on the platform. In the worst case it will end someone's falling on the rails.

So both the escalator on the rise will have to leave, and the entrance to the station in the morning peak limit. This measure is unpleasant, but forced - it is better to create a crowd in an open space or spend too much time on the road to a nearby subway station, you create the potential flea market underground. It is an unwritten law.

It is because of the constant accumulation of people at the station was built the second transition between "Khreschatik" and "Maidan". For the same reason so desperately need a second transition between the "Theater" and "Golden Gate". Unfortunately, not everywhere and not always fulfill the law, and this is very bad, but wherever possible to avoid the notorious big crowd at the station, the choice can be only one. According to current building codes, stations deep foundation with one output should be at least 4 escalators, but on older plants with 3 machines something radically change the already very difficult.

Why escalator repair lasts a month or two? Tunnel escalator - a rather complicated machine with a large number of moving parts: on the same "Polytech" alone, nearly 600 steps, and various bearings about 10 thousand. In contrast to the escalators of floor that we see in various shopping malls, large length of tunnel escalators imposes specific requirements for durability and reliability of their designs.

However, many details are subject to considerable wear, if the escalator would work continuously for a year ladder painting will be held on 28 th. Km. Overhaul of escalators that are set to "Polytechnic Institute" must be performed every 170 thousand. Km. Finally, the escalator - a very important mechanism: for example, by breaking one of the fans the lives of passengers is under the direct threat, and in the case of failure of the escalator consequences can be very unpleasant: the history of accidents were fatal and the former Soviet Union, the recent case with dangling handrail on the "Golden Gate", which injured a man - a very easy example of the possible consequences. Therefore, on the condition of all parts of the escalator depends very much, and given the amount of one night will not replace all.

During the overhaul of the escalator is almost completely disassembled in a clearly defined sequence: first, to dismantle the stairs, then traction chains that pull the ladder painting, guides, devices, responsible for the work of handrails, traction motor, brake, auxiliary drive, gear shafts and more. When this is in place furring escalator and several other parts of the machine, which also pass the inspection and repair. On paper, the description of the repair and maintenance of the escalator takes more than a dozen pages.

Recently at the "Polytechnic Institute" finished dismantling parts repaired escalator. Almost all of them are now taken to workshops escalator services that are located in the electric depot "Darnitsa". Each item must be disassembled, cleaned of dirt and debris, to examine, if necessary, repair or replace the contents, touch up and reassembled. The problem of the accumulation of garbage is very relevant: the soles of shoes people are entered from the street a lot of dirt that remains partially inside the escalator. Some components (reagents for ice control) lead to corrosion of the metal. As practice shows, during the overhaul must be changed to 50% coverage of the stairs - it wears out the most.

After an all-out inspection and repair parts escalator they are set into place in the reverse order. In this case, upon completion of all work on the escalator can let passengers only after a complex checks, run-in and acceptance of regulatory agencies.

Behind the green fence, which appears every time at one of the stations begins escalator repair, nothing special there. There is an overload of equipment and perform some repairs escalator. The most interesting thing is hidden in the engine room, which is under the passengers' feet.

Polurazobrannom escalator and remove overlap on turbine chamber. Big-eyed readers will be able to see a piece of the top stars, which we see below.

Down into the mash. hall. Type about turnstiles, as if we were looking at the escalator to the level we are used to. Left escalator №2, right - №1. №3 hidden behind them on the opposite side of mash. hall. Drives escalators are located at different distances from the input pad, as their size does not allow to put all the equipment between adjacent machines. For those interested in all three escalators have type LT-3, height 49, 4 m.

1st car. Right - the engine brake, left behind a lattice rotates the upper sprocket on which an endless stream flipped stage.

On the other side stands the gear housing, through which the torque from the engine is transmitted to the sprocket.

You can look inside the main structure of the escalator and watch the movement of the inverted steps:

Each escalator equipped with a powerful drive motor, which is to provide start-up the escalator on the rise with the greatest possible load.

On the input shaft of the gearbox is equipped with an automatic brake escalator. The brake must act when disconnected from the engine torque, which provides at least twice the stock while keeping the workload. As a brake, and the entire escalator, crammed with a bunch of very different sensors. The safety of passengers on the escalator depends primarily on the device and at the slightest suspicion of a fatal error (increased speed of the escalator at 30% of installed, spontaneous change of direction of the escalator, running on the rise, etc.) should be escalator be stopped. By the way, note the red emergency stop button at the bottom of the brake.

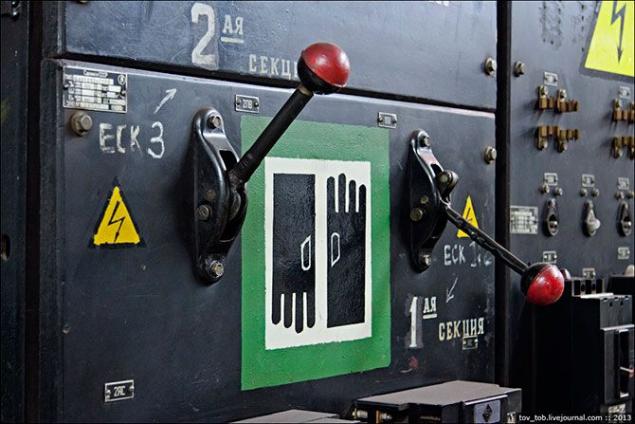

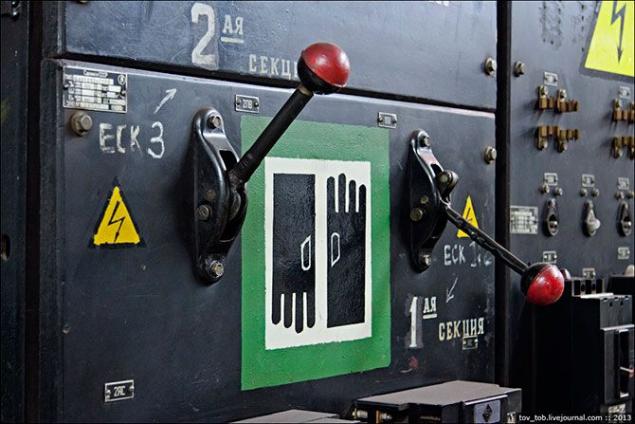

Management of the escalator and control of its various parameters derived from this cabinet. Recent years old electrical equipment at the first station is gradually being replaced by modern electronics, but the question of radical renewal, as always, depends on funding - according to workers escalator service this locker is worth about 900 thousand. UAH.

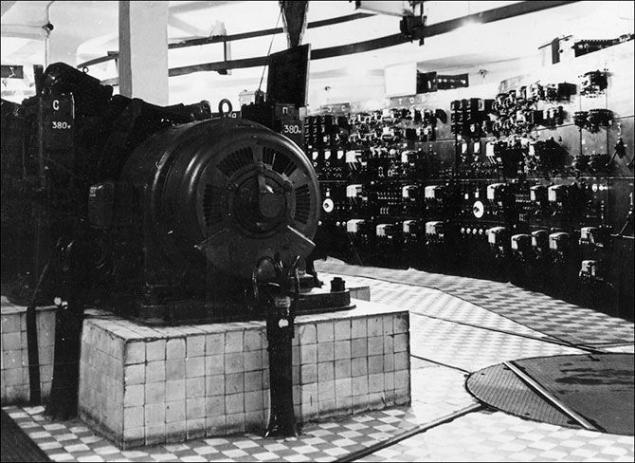

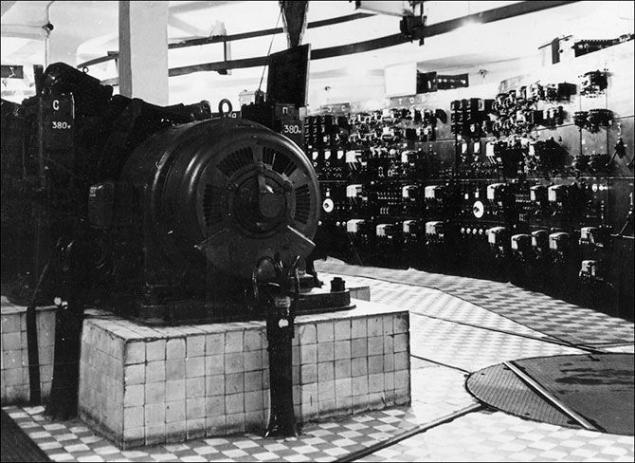

And the computer room for the first stations of the Kiev subway appeared before (it is not "Polytech»):

Huge racks releshkami, fuses, batchfile different pokazometrami and other electrical romance.

In some places, there are still archaisms:

Also preserved and rails with turntable, by which a special trolley for moving cargo control room. In newer computer rooms such "railroad" is no longer.

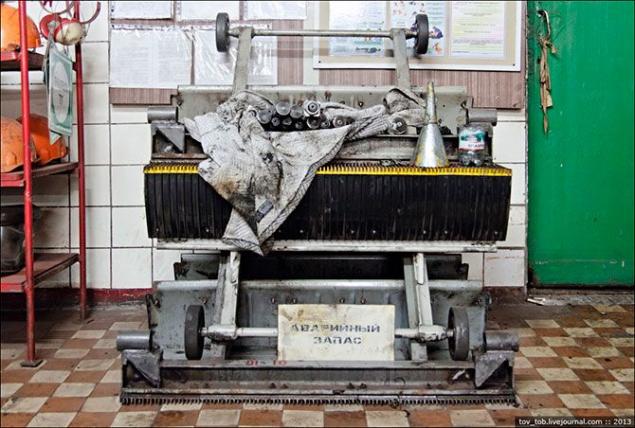

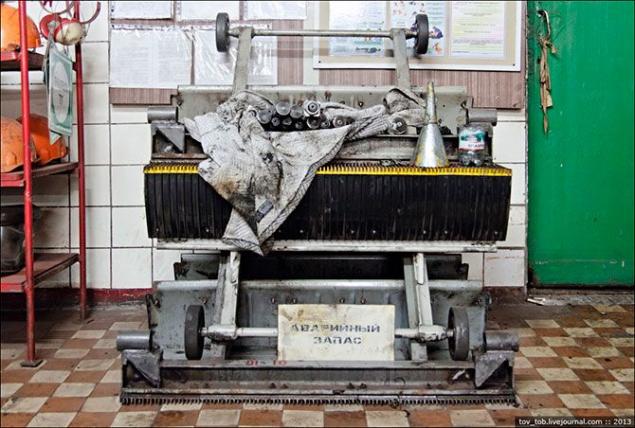

Unplanned shutdown and failure of the escalator - PE. In the control room are always available emergency kits for rapid replacement of defective parts. There's even a backup drive motor:

But let us finally look at the disassembled machine. From what we have seen in the previous photo here was only gearbox and drum brakes. To the left was the engine in the middle you can see the open star.

Near left of the guard.

Reducer. Virtually all the brake components are dismantled.

Main shaft bearings:

The upper sprocket. She hung on the chain, which in turn pulls on the steps themselves.

The force from the engine is transmitted through the gear on the main shaft, which rotates the star:

Call of the passage under the balustrade to service machines between 3rd and 2nd escalator. 100 meters ahead of tightness at 30 °.

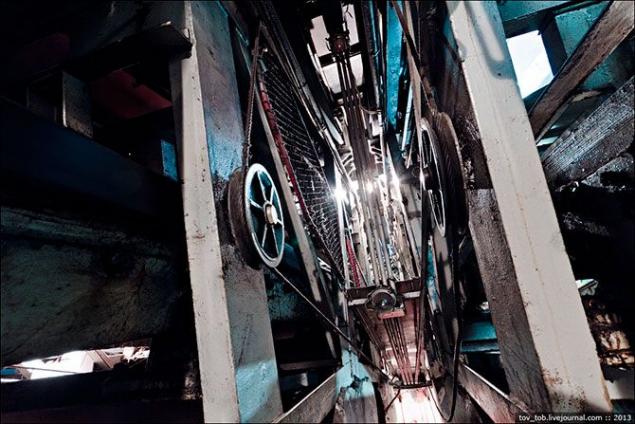

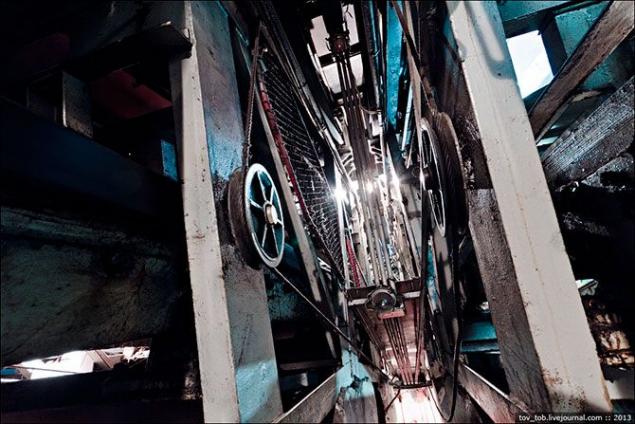

Inside the structures dismantled escalator. In normal times, in the same level steps move in the direction opposite to the main motion.

At the top of the escalator handrail mounted tensioning system:

Considering the great length of the tunnel escalator and constantly changing load without additional dynamic tension handrails and stair cloth can not do.

Stretch fabric ladder takes place under the lower platform of the escalator in the so-called tensioning camera. Here the lower sprocket is in a movable carriage, which with the help of leverage pulled a few goods, which you see on the left.

Lower asterisk disassembled machine:

At the same time let's look at two more stations and see how look more modern machines. Station "Cave" (opened in 1997), the turbine building of the upper angle. 4 machines type ET-3M, height 21, 6 m. Immediately catches the eye more compact arrangement of some nodes: for example, the traction motor is hidden under the top star.

Upper asterisk 4th machine and outdoor gear (photos Cap. Repair 2011):

The control station escalator also more compact and looks more modern:

Turbine Hall Art. "The crude" (2004). There are already installed 4 machines Kryukov UCC-245 with a lifting height of 43 m. In general, the layout is very reminiscent of "Caves", although modern technology and new solutions have had some influence on the design.

Small engine, painted in blue color - is an auxiliary drive, which is used during repair works for the movement of the ladder leaf at a speed of not more than 4 cm / s. There he is on the "Caves" and "Polytechnic Institute».

Wherever you look, everywhere various sensors that monitor the operation of the escalator:

To "Syrets" control station escalator already has electronic stuffing.

According to the list of locks is possible to estimate the number of sensors:

To "Syrets" are also available and freelancers escalator service.

By the way, the longest escalator in Kiev installed at the station. "Khreschatyk" (between the station and access to the street. Gorodetsky). Lifting height - 65, 8 m, the number of steps - 715/743. The escalator was made on spec. order (for escalators type LT-2 maximum lifting height - 65 m).

Source: tov-tob.livejournal.com

Everyone is familiar with this device, someone riding on it every day :)

From January 9 began overhaul escalator №3 Art. "Polytechnic Institute". Such repairs are carried out regularly at all stations, but "Polytech" opened in 1963 and having 3 escalator during repairs pops one annoying trait.

During normal operation, the station in the morning peak flow of people on the way out so that you have to use all three machines: two on the rise and one on the descent. Exactly the same situation in the neighboring "the Station", where the last repair escalators took only a couple of years ago. This means that if one of the escalators stopped for repairs, have to sacrifice something. Leave one escalator on the descent and ascent can not be one-on-one escalator will not be able to remove the entire flow from the bottom and the people will gradually accumulate on the platform. In the worst case it will end someone's falling on the rails.

So both the escalator on the rise will have to leave, and the entrance to the station in the morning peak limit. This measure is unpleasant, but forced - it is better to create a crowd in an open space or spend too much time on the road to a nearby subway station, you create the potential flea market underground. It is an unwritten law.

It is because of the constant accumulation of people at the station was built the second transition between "Khreschatik" and "Maidan". For the same reason so desperately need a second transition between the "Theater" and "Golden Gate". Unfortunately, not everywhere and not always fulfill the law, and this is very bad, but wherever possible to avoid the notorious big crowd at the station, the choice can be only one. According to current building codes, stations deep foundation with one output should be at least 4 escalators, but on older plants with 3 machines something radically change the already very difficult.

Why escalator repair lasts a month or two? Tunnel escalator - a rather complicated machine with a large number of moving parts: on the same "Polytech" alone, nearly 600 steps, and various bearings about 10 thousand. In contrast to the escalators of floor that we see in various shopping malls, large length of tunnel escalators imposes specific requirements for durability and reliability of their designs.

However, many details are subject to considerable wear, if the escalator would work continuously for a year ladder painting will be held on 28 th. Km. Overhaul of escalators that are set to "Polytechnic Institute" must be performed every 170 thousand. Km. Finally, the escalator - a very important mechanism: for example, by breaking one of the fans the lives of passengers is under the direct threat, and in the case of failure of the escalator consequences can be very unpleasant: the history of accidents were fatal and the former Soviet Union, the recent case with dangling handrail on the "Golden Gate", which injured a man - a very easy example of the possible consequences. Therefore, on the condition of all parts of the escalator depends very much, and given the amount of one night will not replace all.

During the overhaul of the escalator is almost completely disassembled in a clearly defined sequence: first, to dismantle the stairs, then traction chains that pull the ladder painting, guides, devices, responsible for the work of handrails, traction motor, brake, auxiliary drive, gear shafts and more. When this is in place furring escalator and several other parts of the machine, which also pass the inspection and repair. On paper, the description of the repair and maintenance of the escalator takes more than a dozen pages.

Recently at the "Polytechnic Institute" finished dismantling parts repaired escalator. Almost all of them are now taken to workshops escalator services that are located in the electric depot "Darnitsa". Each item must be disassembled, cleaned of dirt and debris, to examine, if necessary, repair or replace the contents, touch up and reassembled. The problem of the accumulation of garbage is very relevant: the soles of shoes people are entered from the street a lot of dirt that remains partially inside the escalator. Some components (reagents for ice control) lead to corrosion of the metal. As practice shows, during the overhaul must be changed to 50% coverage of the stairs - it wears out the most.

After an all-out inspection and repair parts escalator they are set into place in the reverse order. In this case, upon completion of all work on the escalator can let passengers only after a complex checks, run-in and acceptance of regulatory agencies.

Behind the green fence, which appears every time at one of the stations begins escalator repair, nothing special there. There is an overload of equipment and perform some repairs escalator. The most interesting thing is hidden in the engine room, which is under the passengers' feet.

Polurazobrannom escalator and remove overlap on turbine chamber. Big-eyed readers will be able to see a piece of the top stars, which we see below.

Down into the mash. hall. Type about turnstiles, as if we were looking at the escalator to the level we are used to. Left escalator №2, right - №1. №3 hidden behind them on the opposite side of mash. hall. Drives escalators are located at different distances from the input pad, as their size does not allow to put all the equipment between adjacent machines. For those interested in all three escalators have type LT-3, height 49, 4 m.

1st car. Right - the engine brake, left behind a lattice rotates the upper sprocket on which an endless stream flipped stage.

On the other side stands the gear housing, through which the torque from the engine is transmitted to the sprocket.

You can look inside the main structure of the escalator and watch the movement of the inverted steps:

Each escalator equipped with a powerful drive motor, which is to provide start-up the escalator on the rise with the greatest possible load.

On the input shaft of the gearbox is equipped with an automatic brake escalator. The brake must act when disconnected from the engine torque, which provides at least twice the stock while keeping the workload. As a brake, and the entire escalator, crammed with a bunch of very different sensors. The safety of passengers on the escalator depends primarily on the device and at the slightest suspicion of a fatal error (increased speed of the escalator at 30% of installed, spontaneous change of direction of the escalator, running on the rise, etc.) should be escalator be stopped. By the way, note the red emergency stop button at the bottom of the brake.

Management of the escalator and control of its various parameters derived from this cabinet. Recent years old electrical equipment at the first station is gradually being replaced by modern electronics, but the question of radical renewal, as always, depends on funding - according to workers escalator service this locker is worth about 900 thousand. UAH.

And the computer room for the first stations of the Kiev subway appeared before (it is not "Polytech»):

Huge racks releshkami, fuses, batchfile different pokazometrami and other electrical romance.

In some places, there are still archaisms:

Also preserved and rails with turntable, by which a special trolley for moving cargo control room. In newer computer rooms such "railroad" is no longer.

Unplanned shutdown and failure of the escalator - PE. In the control room are always available emergency kits for rapid replacement of defective parts. There's even a backup drive motor:

But let us finally look at the disassembled machine. From what we have seen in the previous photo here was only gearbox and drum brakes. To the left was the engine in the middle you can see the open star.

Near left of the guard.

Reducer. Virtually all the brake components are dismantled.

Main shaft bearings:

The upper sprocket. She hung on the chain, which in turn pulls on the steps themselves.

The force from the engine is transmitted through the gear on the main shaft, which rotates the star:

Call of the passage under the balustrade to service machines between 3rd and 2nd escalator. 100 meters ahead of tightness at 30 °.

Inside the structures dismantled escalator. In normal times, in the same level steps move in the direction opposite to the main motion.

At the top of the escalator handrail mounted tensioning system:

Considering the great length of the tunnel escalator and constantly changing load without additional dynamic tension handrails and stair cloth can not do.

Stretch fabric ladder takes place under the lower platform of the escalator in the so-called tensioning camera. Here the lower sprocket is in a movable carriage, which with the help of leverage pulled a few goods, which you see on the left.

Lower asterisk disassembled machine:

At the same time let's look at two more stations and see how look more modern machines. Station "Cave" (opened in 1997), the turbine building of the upper angle. 4 machines type ET-3M, height 21, 6 m. Immediately catches the eye more compact arrangement of some nodes: for example, the traction motor is hidden under the top star.

Upper asterisk 4th machine and outdoor gear (photos Cap. Repair 2011):

The control station escalator also more compact and looks more modern:

Turbine Hall Art. "The crude" (2004). There are already installed 4 machines Kryukov UCC-245 with a lifting height of 43 m. In general, the layout is very reminiscent of "Caves", although modern technology and new solutions have had some influence on the design.

Small engine, painted in blue color - is an auxiliary drive, which is used during repair works for the movement of the ladder leaf at a speed of not more than 4 cm / s. There he is on the "Caves" and "Polytechnic Institute».

Wherever you look, everywhere various sensors that monitor the operation of the escalator:

To "Syrets" control station escalator already has electronic stuffing.

According to the list of locks is possible to estimate the number of sensors:

To "Syrets" are also available and freelancers escalator service.

By the way, the longest escalator in Kiev installed at the station. "Khreschatyk" (between the station and access to the street. Gorodetsky). Lifting height - 65, 8 m, the number of steps - 715/743. The escalator was made on spec. order (for escalators type LT-2 maximum lifting height - 65 m).

Source: tov-tob.livejournal.com