416

Rapid prototyping - modern method of manufacturing 3d parts

Fifty million twenty seven thousand one hundred sixty four

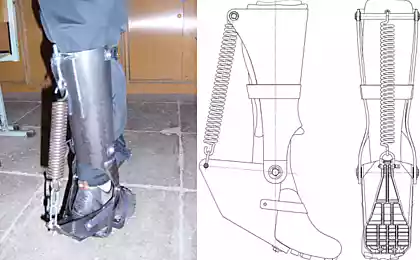

Using today's popular 3D printing models (prototypes) of different complexity parts. The layouts are printed on special printers and can be used as a full-fledged prototypes for testing and further adjustment of any design. The company PressLitye offers rapid prototyping using FDM technology. We use high-tech installations and special polymer materials, ensures greater precision of the manufacture of parts.

The principles of innovative technology

With FDM development to create 3D models with the specified parameters by using a system design CAD. The work is performed by layer-by-layer stacking of the polymer fibers. Such threads are extruded from the drawplate – steel fixture with a plurality of holes, and stacked along the contours of the created form. The process of "growing" continues until the moment of full volume of the sample.

The work is done through the use of install a FORTUS 400 mc 3d printer with high technology features. Details on such device it are not only strong, but also durable. We are using high quality polymer materials with the following characteristics:

Polymer models perfectly withstand mechanical stress and are considered functional.

Details of collapsible type

Such models must be equipped with connecting elements to be assembled from plastic parts a future design. The use of screws for this purpose did not give effective solutions to the problem. The number of screw-ins was limited. After 3-4 times the hole for the screw was just destroyed. In the end began to use an ordinary screw, and the hole under it is equipped with a metal bushing with thread. Now the assembling of the structure or its disassembly can be performed repeatedly without compromising the integrity of the parts.

The sizes of cores:

Quotations

The cost of making a 3D prototype is defined for each order individually. This takes into account features of the model and its dimensions. From these conditions depend on the terms of producing of the layout. Developed models using special CAD service, which would require a sketch or drawing.

Using today's popular 3D printing models (prototypes) of different complexity parts. The layouts are printed on special printers and can be used as a full-fledged prototypes for testing and further adjustment of any design. The company PressLitye offers rapid prototyping using FDM technology. We use high-tech installations and special polymer materials, ensures greater precision of the manufacture of parts.

The principles of innovative technology

With FDM development to create 3D models with the specified parameters by using a system design CAD. The work is performed by layer-by-layer stacking of the polymer fibers. Such threads are extruded from the drawplate – steel fixture with a plurality of holes, and stacked along the contours of the created form. The process of "growing" continues until the moment of full volume of the sample.

The work is done through the use of install a FORTUS 400 mc 3d printer with high technology features. Details on such device it are not only strong, but also durable. We are using high quality polymer materials with the following characteristics:

- resistance to deformation and thermal impact;

- high durability;

- zero water absorption;

- the ability to produce parts with minimal errors.

Polymer models perfectly withstand mechanical stress and are considered functional.

Details of collapsible type

Such models must be equipped with connecting elements to be assembled from plastic parts a future design. The use of screws for this purpose did not give effective solutions to the problem. The number of screw-ins was limited. After 3-4 times the hole for the screw was just destroyed. In the end began to use an ordinary screw, and the hole under it is equipped with a metal bushing with thread. Now the assembling of the structure or its disassembly can be performed repeatedly without compromising the integrity of the parts.

The sizes of cores:

- with diameter 2.5 – 5.0 mm – to be used more often;

- with diameter 6 – 8 mm are used for special orders.

Quotations

The cost of making a 3D prototype is defined for each order individually. This takes into account features of the model and its dimensions. From these conditions depend on the terms of producing of the layout. Developed models using special CAD service, which would require a sketch or drawing.