741

Rules of work with copper tubing

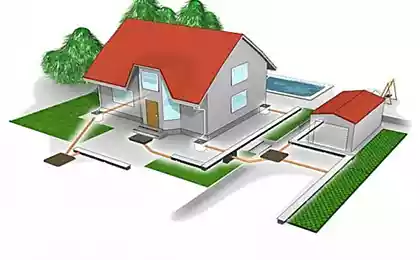

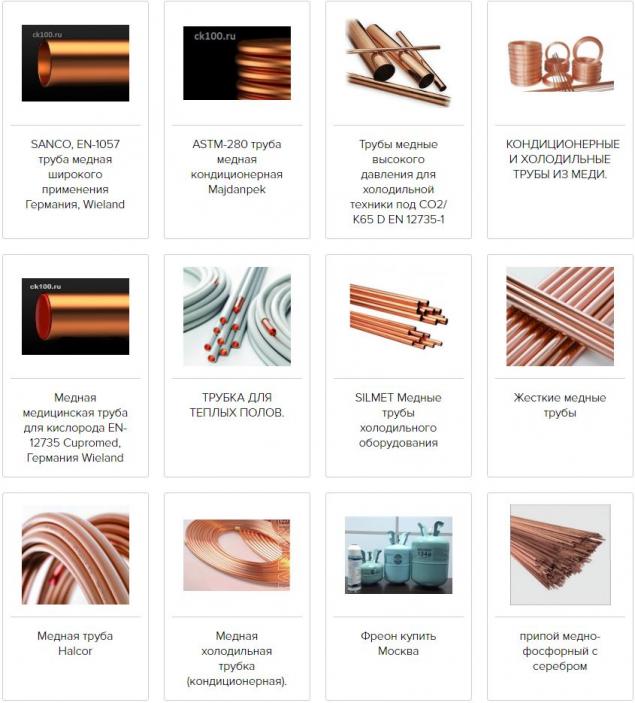

Practice and time have proved the reliability and feasibility of using copper pipes in creating pipe lines. But flawless copper has individual characteristics that should be considered to the mounted pipeline served the promised 50 years, instead of the average 20. And before you buy the copper pipe will have the details to provide specifics of their operation as elements of plumbing, heating and other systems.

Operating limitations

Copper pipes are known for their endurance, they can handle everything and repeated alternate freezing and thawing, pressure surge and temperature drop, but not resistant to mechanical damage. Therefore, when the outer strip is aesthetically pleasing tubing must be placed so as to exclude the possibility of mechanical damage.

The softness of copper requires mandatory installation of mechanical water purification filters, to prevent erosion, which can occur in response to mechanical action present in water sand and small stone chips.

The hardness of water below and above the 1.42 to 3.1 mg/l for a few years, reducing the service life of copper pipes. The fact that chlorinated water for copper's a favorite habitat. Unpleasant chlorine makes us a natural oxide film on the walls of copper pipes virtually impenetrable protective armor. If the water hardness does not correspond to the norm, this armor is destroyed first, and then under the action of the chlorine is restored again. A constant process of re-straining the resources of the metal and eliminates the advantage of copper as a survivor.

Technical limitations

For the installation of the system is not required to be a top expert, but you should take into account the subtleties of the process. To bend copper tube for air conditioning and not only should be using a special tool. If, during bending, the tube is wrinkled, you only have one chance to rectify the situation. If it fails, the damaged area is cut away.

Using to create connections to solder, do not overheat, it threatens loss of strength up to the subsequent rupture of the pipe. After applying flux, its residues should be washed off as being the aggressor against copper it can cause corrosion.

Typically, the system is recommended to mount from the same material, but in practice it doesn't always work. Therefore, in order to ensure electrochemical compatibility of the highway, as adapters between the copper and pipes of other materials it is recommended to use bronze or brass fittings.

To the copper pipes did not cause the premature corrosion of the system elements of another metal must observe the rules of priority. Focusing on the direction of water flow, the copper is placed after the elements made, for example, of steel, zinc or iron.

Requirements, in fact, not difficult, but compliance with them will save you from repairs and accidents of the pipeline systems will remain in perfect condition 80 years later.

According to the website ck100.ru/

An operational detective bureau is on guard for the interests of its clients!

The storyline and development of the action in GTA 5