455

The most durable wood

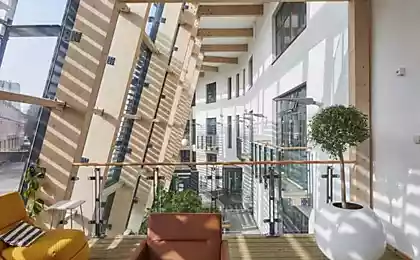

An international group of companies Accsys Group has developed an environmentally friendly method of chemical modification of wood significantly improves its strength and durability both on land and under water.

The technology of acetylation is in the handling of wood in all its depth with acetic anhydride to bind the hydroxyl group of molecules and its replacement on acetyl. This substitution eliminates the cause of deformations in wood of those substances which are susceptible to rotting.

The acetylated wood Accoya looks no different from ordinary, at first a faint smell of vinegar reminds of the used technology. The presence of acid leads to the need to use stainless fasteners. There are no other restrictions, on the contrary, the scope of the treated wood considerably expanded.

It can be used in ship building, as load-bearing structures of road bridges due to increased strength, moistureproof veneer facades, to create coatings with any natural or artificial pond. Increased thermal insulation characteristics of wood provide it with high energy efficiency.

The wood is radiata pine grown in controlled renewable forestry. Acetylation makes the wood inedible to insects, but does not prevent its recycling or incineration as biomass. Products received gold Cradle to Cradle certificate confirming the waste-free technology.

Accoya wood is produced in Holland. Under warranty, it will last at least 50 years on land and 25 years of immersion in fresh water. According to experts, the lifetime can reach 70 years or more. The acetylated wood is exported to 25 countries, which already successfully implemented sustainable infrastructure, public buildings and private homes. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: hvoya.wordpress.com/2017/02/01/accoya/

The technology of acetylation is in the handling of wood in all its depth with acetic anhydride to bind the hydroxyl group of molecules and its replacement on acetyl. This substitution eliminates the cause of deformations in wood of those substances which are susceptible to rotting.

The acetylated wood Accoya looks no different from ordinary, at first a faint smell of vinegar reminds of the used technology. The presence of acid leads to the need to use stainless fasteners. There are no other restrictions, on the contrary, the scope of the treated wood considerably expanded.

It can be used in ship building, as load-bearing structures of road bridges due to increased strength, moistureproof veneer facades, to create coatings with any natural or artificial pond. Increased thermal insulation characteristics of wood provide it with high energy efficiency.

The wood is radiata pine grown in controlled renewable forestry. Acetylation makes the wood inedible to insects, but does not prevent its recycling or incineration as biomass. Products received gold Cradle to Cradle certificate confirming the waste-free technology.

Accoya wood is produced in Holland. Under warranty, it will last at least 50 years on land and 25 years of immersion in fresh water. According to experts, the lifetime can reach 70 years or more. The acetylated wood is exported to 25 countries, which already successfully implemented sustainable infrastructure, public buildings and private homes. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: hvoya.wordpress.com/2017/02/01/accoya/

Exercises to rejuvenate the glands of internal secretion

Don't involve children in a family quarrel!