623

ThermoWood is a unique building material

Unique natural material for building houses is wood, but over time the wooden structure under the influence of moisture and temperature changes can deform and lose its original appearance. But not TMW.

ThermoWood is a new construction material with improved performance. New old wood gets special properties due to its heat treatment with hot air with steam without the use of preservatives and chemicals. The result is a material with exceptional environmental friendliness.

Heat treatment of wood takes place in the temperature range from 160 to 250 degrees and at elevated pressure, causing the surface of the wood acquires a new "anatomical" elements or, in other words, the structure is changed the thermo. All components that make up the wood, and it is cellulose, hemicellulose, lignin, etc., are changing radically. However, they lose some of their properties and acquire others.

Thus, in particular, the tree loses the ability to absorb moisture and turns into material unsuitable for life of microorganisms and fungi. This tree does not rot.

During heat treatment of wood, made of softwood, because of its composition mainly removes resins, and those that remain in small quantities, polimerizuet and stored inside the tree as a hard polymer. The strength of such wood becomes greater than it was before heat treatment.

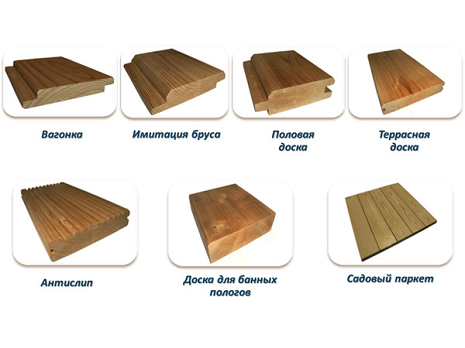

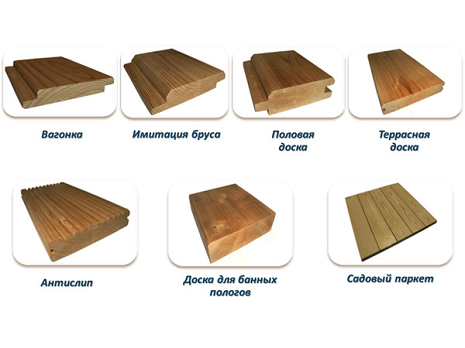

Changes in the structure of ThermoWood has significantly expanded the scope of application of wood as a building material. That just does not make the thermo! This is a common and garden flooring, lining, planed Board, timber, decking and much more.

The design and profile of heat-treated boards are obtained the same as a normal wooden Board.This assortment of products of ThermoWood allows its use for exterior and interior works. ThermoWood is used in the construction of houses for various purposes, and in the manufacture of furniture, doors, Windows and even musical instruments. In addition, the thermo do flooring, paving and terrace area in front of the pools, arrange track, make arbors and stairs, able to withstand heavy loads. These products don't wear out over the years. Indeed Royal material!

Planking is used for decoration of facades of buildings

Thermally treated wood was in great demand in facade and interior works. The case of the facades of the frame (easy to construct) buildings used planking. This thermally treated wood, which creates a smooth vertical or horizontal surface without visible fixing elements. For this purpose, thermococci without a groove and tenon.

The basis of such a facade design are the guides of bars with a cross section of 20 x 40 mm and a standard step is set to 600 mm. Lined with thermodosa facade is a ventilated design.

When facing facades with preference for Thermozone or ash. To design projects best suited ash.

When using the thermo out surprisingly beautiful smooth flooring. Due to the density and uniformity thermodevices plate made of her gender has no cracks and does not need additional ties.

You can combine thermodosa and with traditional boards.

Industry produces thermococci thickness of 15 and 18 mm, width — 77, 90, 150 and 190 mm. For the manufacture of floor can be used in Board of moderate and intensive heat treatment (refer to profile F 2 and F 3).

In addition to traditional thermococci, in the construction of everyday life includes the so-called engineering thermodosa profile (F6), which consists of three layers. This is the top layer made of solid wood, the middle layer is assembled from transverse bands of thermally modified timber, and the thin bottom layer of wood fibers, arranged longitudinally. Such boards are produced without any cover, which gives consumers the opportunity to apply varnishes and paints at its own discretion.We all know that regular wood is constantly changing its shape to warp. Heat-treated wood has improved dimensional stabilization under different methods of sawing — tangential and radial.

The technology of manufacturing the thermo is quite time-consuming. This fact and the excellent performance properties obtained in this work form relatively high cost of ThermoWood — from 1300 to 5000 rubles per square meter. Expensive, but very high quality: built from thermo-wood buildings will delight you for many decades. While maintaining the quality and unchanged.

ThermoWood is a relatively new offer in the Russian market of construction materials. The first technology of heat treatment of wood appeared in Finland in the late 1990-ies. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: estp-blog.ru/rubrics/rid-10593/

ThermoWood is a new construction material with improved performance. New old wood gets special properties due to its heat treatment with hot air with steam without the use of preservatives and chemicals. The result is a material with exceptional environmental friendliness.

Heat treatment of wood takes place in the temperature range from 160 to 250 degrees and at elevated pressure, causing the surface of the wood acquires a new "anatomical" elements or, in other words, the structure is changed the thermo. All components that make up the wood, and it is cellulose, hemicellulose, lignin, etc., are changing radically. However, they lose some of their properties and acquire others.

Thus, in particular, the tree loses the ability to absorb moisture and turns into material unsuitable for life of microorganisms and fungi. This tree does not rot.

During heat treatment of wood, made of softwood, because of its composition mainly removes resins, and those that remain in small quantities, polimerizuet and stored inside the tree as a hard polymer. The strength of such wood becomes greater than it was before heat treatment.

Changes in the structure of ThermoWood has significantly expanded the scope of application of wood as a building material. That just does not make the thermo! This is a common and garden flooring, lining, planed Board, timber, decking and much more.

The design and profile of heat-treated boards are obtained the same as a normal wooden Board.This assortment of products of ThermoWood allows its use for exterior and interior works. ThermoWood is used in the construction of houses for various purposes, and in the manufacture of furniture, doors, Windows and even musical instruments. In addition, the thermo do flooring, paving and terrace area in front of the pools, arrange track, make arbors and stairs, able to withstand heavy loads. These products don't wear out over the years. Indeed Royal material!

Planking is used for decoration of facades of buildings

Thermally treated wood was in great demand in facade and interior works. The case of the facades of the frame (easy to construct) buildings used planking. This thermally treated wood, which creates a smooth vertical or horizontal surface without visible fixing elements. For this purpose, thermococci without a groove and tenon.

The basis of such a facade design are the guides of bars with a cross section of 20 x 40 mm and a standard step is set to 600 mm. Lined with thermodosa facade is a ventilated design.

When facing facades with preference for Thermozone or ash. To design projects best suited ash.

When using the thermo out surprisingly beautiful smooth flooring. Due to the density and uniformity thermodevices plate made of her gender has no cracks and does not need additional ties.

You can combine thermodosa and with traditional boards.

Industry produces thermococci thickness of 15 and 18 mm, width — 77, 90, 150 and 190 mm. For the manufacture of floor can be used in Board of moderate and intensive heat treatment (refer to profile F 2 and F 3).

In addition to traditional thermococci, in the construction of everyday life includes the so-called engineering thermodosa profile (F6), which consists of three layers. This is the top layer made of solid wood, the middle layer is assembled from transverse bands of thermally modified timber, and the thin bottom layer of wood fibers, arranged longitudinally. Such boards are produced without any cover, which gives consumers the opportunity to apply varnishes and paints at its own discretion.We all know that regular wood is constantly changing its shape to warp. Heat-treated wood has improved dimensional stabilization under different methods of sawing — tangential and radial.

The technology of manufacturing the thermo is quite time-consuming. This fact and the excellent performance properties obtained in this work form relatively high cost of ThermoWood — from 1300 to 5000 rubles per square meter. Expensive, but very high quality: built from thermo-wood buildings will delight you for many decades. While maintaining the quality and unchanged.

ThermoWood is a relatively new offer in the Russian market of construction materials. The first technology of heat treatment of wood appeared in Finland in the late 1990-ies. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: estp-blog.ru/rubrics/rid-10593/