651

ThermoWood: features material

The tree is one of the most popular building and finishing materials, which accompanies us from ancient times to the present day.

But in recent years the growing popularity of its special kind – ThermoWood with improved characteristics and extended scope.

What is ThermoWood

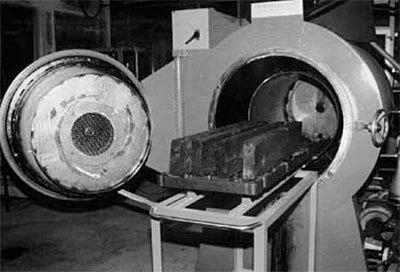

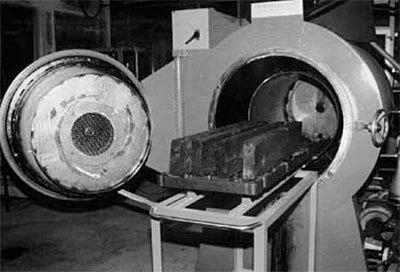

ThermoWood is the result of a special heat treatment of various coniferous and deciduous wood (pine, ash, oak and others). The other name of the material – thermally modified wood (TMD) or thermo wood. Depending on the country of manufacturer, production of TMD may differ, but the maximum widespread Finnish technology. Its essence lies in the thermal hydrolysis of wood under limited access of air in the atmosphere of water vapor at high temperatures (150-240⁰С).

Heat treatment may be single-stage and multi-stage, in the second case, steam is supplied under pressure (1,6 Bar). There is also a rectification under pressure is not air, vapor, and inert gas (nitrogen), in this way TMD is made of the highest quality.

Depending on the temperature of the steam, which is treated wood, it is divided into classes of differing appearance and properties.

History of thermo

Make the tree stronger and more durable tried since ancient times – he was boiled in oil or a salt solution, soaked, burned. The first scientific researches in the field of thermal processing of wood date back to the thirties of the last century – the pioneers were the Germans, Strain and Hansen. In America, talking about the material a little later, in the forties, and the first results of scientific works on this topic were published only in the sixties of the past century (Kallman, Schneider).

Interested in the process in other countries, such as France and the Netherlands (Holland), but most seriously the problem approached Finns in the nineties, having developed technology for thermal modification by water vapor at high temperatures. Today, the production of TMD is widely spread in Europe and America, and our country.

Properties of ThermoWood

As a result of thermal modification of wood improves nearly all parameters. It becomes:

Resistant to external environment – through the acquisition of more dense structure maximally decreases water absorption, the wood ceases to absorb moisture. It is no longer valid not only for couples, even straight water will not affect the material, and when completely submerged in aquatic environments for long periods of time moisture will accumulate no more than 8 % of the total weight. Rain, snow, fog, and other vagaries of nature ThermoWood, unlike usual, will take quite calmly.

Stable always look at the geometry and dimensions, there is no danger of getting a "helicopter" instead of a flat Board. Moreover, there is no cracking.

Durable – even relatively mild initial variant of the varieties after treatment become hard and resistant to mechanical damage. The wood is characteristic dents from bumps and scratches Mar the surface very hard and intentionally, not by chance.

Safe – and it is not only the preservation of naturalness and sustainability, but also improve the grade of fire resistance, ThermoWood is poorly ignited and bad erupted.

Decorative – clearly drawn texture, brighter, richer, and becomes more uniform shade.

Durable – increases service life, both indoors and for exterior use. This is due to resistance to pathogenic microflora (mold, mildew), rotting and pests.

On the background of the list of advantages, the most significant drawback of TMD is its high cost, but if you take into account the almost infinite lifetime and the properties, this disadvantage is losing its relevance.

Scope

Due to the modification of the thermally modified timber greatly extends the scope of application.

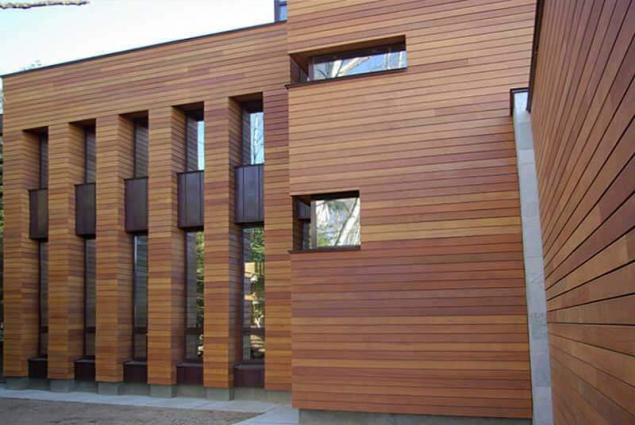

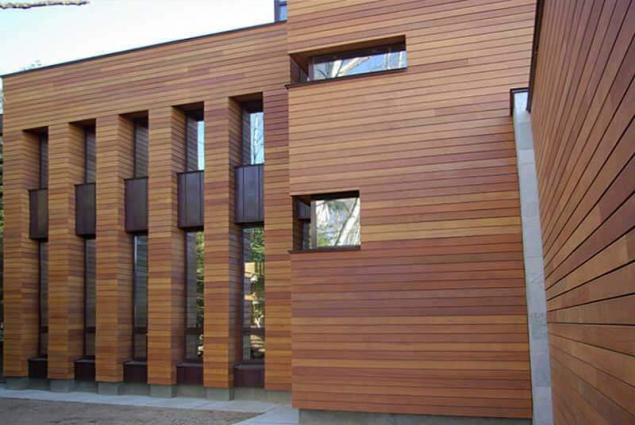

TMW is one of the most durable solutions to the external facade and terraces of the wooden house, a cottage, a garden gazebo or outdoor coverage.

It is versatile, universally popular material.

Thermodosa on the façade – often the planking, wall paneling, block-house. Facing the years, retains the look, you can forget about drying up, cracking and rot. Such a facade requires a minimum of maintenance during operation.

Thermodosa on the terraces, verandas and pergolas – outdoor and unheated areas require the use of wear-resistant coatings, thermodosa not afraid of falling rain, temperature fluctuations. On the floor there will be cracks, will crack and will not warp, will not have each season to cover up and repaint the floor.

Thermodosa in wet areas – sauna, bathhouse, bathrooms and areas around swimming pools are also demanding to finish, but because of the constant high humidity or direct contact with water. In addition, TMD is a poor conductor of heat and does not heat up.

Thermodosa for tracks – track not only decorate the area and easy access in any weather, but subjected to high stress, exposure to rain and moisture. Track from TMD natural and decorative, with the most reliable and durable.

published

Source: www.forumhouse.ru/articles/house/6853

But in recent years the growing popularity of its special kind – ThermoWood with improved characteristics and extended scope.

What is ThermoWood

ThermoWood is the result of a special heat treatment of various coniferous and deciduous wood (pine, ash, oak and others). The other name of the material – thermally modified wood (TMD) or thermo wood. Depending on the country of manufacturer, production of TMD may differ, but the maximum widespread Finnish technology. Its essence lies in the thermal hydrolysis of wood under limited access of air in the atmosphere of water vapor at high temperatures (150-240⁰С).

Heat treatment may be single-stage and multi-stage, in the second case, steam is supplied under pressure (1,6 Bar). There is also a rectification under pressure is not air, vapor, and inert gas (nitrogen), in this way TMD is made of the highest quality.

Depending on the temperature of the steam, which is treated wood, it is divided into classes of differing appearance and properties.

- Pairs to 190⁰С first class, easy change of shade, minimal enhancement.

- Pairs to 210⁰С – second class, more dark tone, increasing the strength and resistance to rot.

- Pairs to 240⁰С – third class (the highest), dark, rich shades, maximum density, hardness, strength.

History of thermo

Make the tree stronger and more durable tried since ancient times – he was boiled in oil or a salt solution, soaked, burned. The first scientific researches in the field of thermal processing of wood date back to the thirties of the last century – the pioneers were the Germans, Strain and Hansen. In America, talking about the material a little later, in the forties, and the first results of scientific works on this topic were published only in the sixties of the past century (Kallman, Schneider).

Interested in the process in other countries, such as France and the Netherlands (Holland), but most seriously the problem approached Finns in the nineties, having developed technology for thermal modification by water vapor at high temperatures. Today, the production of TMD is widely spread in Europe and America, and our country.

Properties of ThermoWood

As a result of thermal modification of wood improves nearly all parameters. It becomes:

Resistant to external environment – through the acquisition of more dense structure maximally decreases water absorption, the wood ceases to absorb moisture. It is no longer valid not only for couples, even straight water will not affect the material, and when completely submerged in aquatic environments for long periods of time moisture will accumulate no more than 8 % of the total weight. Rain, snow, fog, and other vagaries of nature ThermoWood, unlike usual, will take quite calmly.

Stable always look at the geometry and dimensions, there is no danger of getting a "helicopter" instead of a flat Board. Moreover, there is no cracking.

Durable – even relatively mild initial variant of the varieties after treatment become hard and resistant to mechanical damage. The wood is characteristic dents from bumps and scratches Mar the surface very hard and intentionally, not by chance.

Safe – and it is not only the preservation of naturalness and sustainability, but also improve the grade of fire resistance, ThermoWood is poorly ignited and bad erupted.

Decorative – clearly drawn texture, brighter, richer, and becomes more uniform shade.

Durable – increases service life, both indoors and for exterior use. This is due to resistance to pathogenic microflora (mold, mildew), rotting and pests.

On the background of the list of advantages, the most significant drawback of TMD is its high cost, but if you take into account the almost infinite lifetime and the properties, this disadvantage is losing its relevance.

Scope

Due to the modification of the thermally modified timber greatly extends the scope of application.

TMW is one of the most durable solutions to the external facade and terraces of the wooden house, a cottage, a garden gazebo or outdoor coverage.

It is versatile, universally popular material.

Thermodosa on the façade – often the planking, wall paneling, block-house. Facing the years, retains the look, you can forget about drying up, cracking and rot. Such a facade requires a minimum of maintenance during operation.

Thermodosa on the terraces, verandas and pergolas – outdoor and unheated areas require the use of wear-resistant coatings, thermodosa not afraid of falling rain, temperature fluctuations. On the floor there will be cracks, will crack and will not warp, will not have each season to cover up and repaint the floor.

Thermodosa in wet areas – sauna, bathhouse, bathrooms and areas around swimming pools are also demanding to finish, but because of the constant high humidity or direct contact with water. In addition, TMD is a poor conductor of heat and does not heat up.

Thermodosa for tracks – track not only decorate the area and easy access in any weather, but subjected to high stress, exposure to rain and moisture. Track from TMD natural and decorative, with the most reliable and durable.

published

Source: www.forumhouse.ru/articles/house/6853