471

Thermal imaging survey: modern not destroying control technology

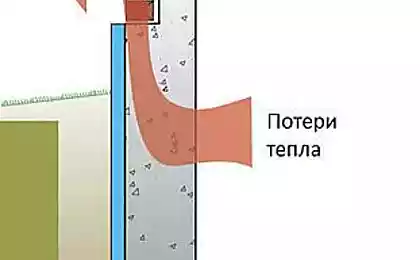

Thermal imaging inspection of engineering structures is the only modern method of evaluation of heat losses arising in consequence of the breach in the thermal protection structures of the walls and floors, as well as to identify some other problems that arose during the construction and operation of buildings and structures.

Basically the thermal imaging survey is used in identifying construction defects, assessment of the current state of insulation of the buildings, specification of the actual heat loss and the heat transfer resistance of structures. The procedure of the thermal imaging survey is carried out using a tool capable of detecting infrared radiation from objects, in this case with a thermal imager FLIR T335. The method used a thermal imaging survey is not destructive and it is completely safe for the surveyed buildings and structures.

The technique of thermal imaging survey is not a difficult operation: a thermal imaging camera works in the infrared region of the electromagnetic spectrum and taking it produces the visualization of data obtained from the test object into a visible image. Sensing infrared radiation, the matrix of the device converts it into an electrical signal, which after processing by the processor is displayed on the screen of the device.

The thus obtained visual data is called a thermogram. The accuracy of the method a thermal imaging survey is very high, the margin of error is properly calibrated imager typically less than ± 1 oC. After thermal imaging, the received data is processed by the specialist and the results of the surveys provide a technical report that displays all the collected data with emphasis on problem areas.

Thermal imaging inspection of buildings and structures has some significant advantages compared to other methods of finding these problems:

This illustration of the method (the results of thermal imaging surveys creates a detailed technical report with the exact description of the obtained results, indicating problem areas with teplopoteri etc.); a Method of thermal imaging inspections of engineering structures is non-destructive testing (thermal imaging inspection can cause labored building construction, for holding obsledovaniya require any dismantling); High precision and reliability of the results (the data obtained are precise geometric relation to the object of study, to determine the localization of the points of heat loss in the design, the error of the instrument does not exceed ± 1 oC); Mobility method the small size of the imager guarantees high mobility and ease of use, examination can be carried out in the most remote places and the preparation for it will not take much time, as well as the process itself); affordability (thermal imaging inspection can afford almost any organization or individual, the cost of conducting the thermal imaging survey of a lot less than the economic effect from them. Thus we can say that the Arsenal of modern methods used in construction were added, they added a thermal imaging survey.published

Source: www.diy.ru/blog/rtgeolog/post/8446/

Basically the thermal imaging survey is used in identifying construction defects, assessment of the current state of insulation of the buildings, specification of the actual heat loss and the heat transfer resistance of structures. The procedure of the thermal imaging survey is carried out using a tool capable of detecting infrared radiation from objects, in this case with a thermal imager FLIR T335. The method used a thermal imaging survey is not destructive and it is completely safe for the surveyed buildings and structures.

The technique of thermal imaging survey is not a difficult operation: a thermal imaging camera works in the infrared region of the electromagnetic spectrum and taking it produces the visualization of data obtained from the test object into a visible image. Sensing infrared radiation, the matrix of the device converts it into an electrical signal, which after processing by the processor is displayed on the screen of the device.

The thus obtained visual data is called a thermogram. The accuracy of the method a thermal imaging survey is very high, the margin of error is properly calibrated imager typically less than ± 1 oC. After thermal imaging, the received data is processed by the specialist and the results of the surveys provide a technical report that displays all the collected data with emphasis on problem areas.

Thermal imaging inspection of buildings and structures has some significant advantages compared to other methods of finding these problems:

This illustration of the method (the results of thermal imaging surveys creates a detailed technical report with the exact description of the obtained results, indicating problem areas with teplopoteri etc.); a Method of thermal imaging inspections of engineering structures is non-destructive testing (thermal imaging inspection can cause labored building construction, for holding obsledovaniya require any dismantling); High precision and reliability of the results (the data obtained are precise geometric relation to the object of study, to determine the localization of the points of heat loss in the design, the error of the instrument does not exceed ± 1 oC); Mobility method the small size of the imager guarantees high mobility and ease of use, examination can be carried out in the most remote places and the preparation for it will not take much time, as well as the process itself); affordability (thermal imaging inspection can afford almost any organization or individual, the cost of conducting the thermal imaging survey of a lot less than the economic effect from them. Thus we can say that the Arsenal of modern methods used in construction were added, they added a thermal imaging survey.published

Source: www.diy.ru/blog/rtgeolog/post/8446/