448

Bolotov sugar — Sugar is WITHOUT POISON

What is sugar?

Sugar - household name sucrose (C12H22O11) is an important food product. Regular sugar (sucrose) refers to carbohydrates that are considered valuable nutrients that provide the body with the necessary energy. Sugar can be obtained in different ways: from oil, gas, wood, etc. But the most cost-effective way of getting a sugar processing beet and a special type of cane, that is called the sugar — cane.

Thirty three million four hundred sixty four thousand eight hundred eighty

How to produce sugar

Sugar production from sugar beet is a traditional sector of the food industry of Ukraine. Sugar beet is a bulky and perishable product, so the factories for its processing are usually built close to plantations.

The technological process of production of beet sugar comprises the following stages:

Extraction. First the beets are washed, then cut into chips, which are loaded into the diffuser where the sugar is extracted from plant material with hot water. The result is a "diffusion juice" containing 10 to 15% sucrose.

Cleaning. The diffusion juice is mixed in a saturator with milk of lime. In this case heavy impurities are deposited. Then through the heated solution is passed carbon dioxide to lime tied Asahara. Filtering, get the so-called"purified juice." Whitening includes passing sulfur dioxide through it, and then filtration through activated charcoal.

Evaporation. Excess water is removed by evaporation. Received eventually the liquid contains from 50 to 65% sugar.

Crystallization. The crystallization is carried out in a huge vacuum vessel with a height of sometimes six-bedroom house. Product of crystallization, the massecuite is a mixture of molasses with sucrose crystals. These components are separated by centrifugation, and the resulting solid dried sugar.

In the production of sugar by conventional techniques used disinfectants: formaldehyde, bleach, poisons amine group (basin, ambisol, as well as combinations of the above substances), hydrogen peroxide and others. Disinfectants are used to kill the microflora in a sugar solution, to disinfect the water coming into production.

Toxic effect of toxic substances is caused by the reactions of compounds of toxins with organic molecules with the formation of complex substances more toxic than the original. For example, bleach or bleach(CaCl2О) in the interaction in the water molecule amines to form Dioxins. The toxicity of Dioxins is higher chlorine toxicity 107 times, 67 times higher than the toxicity of potassium Cyanide and 500 times higher than the rat poison Strychnine.

Formaldehyde is a mutagen, carcinogen and is prohibited in use in contact with food. So our sugar annually receive temporary permits for the use of these substances in the food industry. Upon contact with the sucrose to 11% connected with formaldehyde, and part of this compound remains in the Sahara.

By evaporation to reduce the scale in the sugar syrup add antiscales (chelators of the type Antiplex). The complex molecule captures an ion of calcium, magnesium, etc., neutralizing the positive charge. As a result, this molecule does not stick to the heating surface, but remains in solution and accumulates in the sugar and molasses. And sugar comes to us in the body.

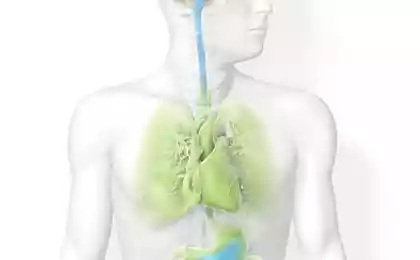

In the human body the chelating agent easily enters the bloodstream and accumulates in the thin capillaries. If vasoconstriction of the capillary, the probability of blockage increases dramatically (thrombosis). The consequences of thrombosis in the human body, especially in the human brain, known stroke.

In addition, to reduce surface tension of viscous solutions surfactants are used (detergent — sodium phosphate). To reduce foam are also used defoamers, flocculants — substances which increase the deposition of suspended particles.

To get white, clean and refined sugar, it must pass through the filter of cow bones. For the production of refined sugar beef bone char is used.

Fifty four million five hundred thirty six thousand three hundred fifty four

Than sugar Bolotov different from the usual

A group of academician Bolotov B. V. developed the complex of measures allowing to completely eliminate the use of chemicals in the production of sugar.

For cleaning sugar group of academician Bolotov used method of energy-information processes for the decontamination of bacterial environments and to combat the putrefactive processes to accelerate crystallization and reduce scale formation.

The application of the alternating magnetic field affects an offset of the response to Ca2+ and in the existing technology allows to reduce the use of milk of lime (calcium saharat three) that the end result reduces the content of calcium salts in purified sulphited juice.

On the other hand use alternating magnetic fields, accelerates sugar crystallization, improves the quality of the crystal mass, the yield of sucrose is increased; a decrease in the content of sucrose in molasses, “flour”, small crystal, reduces the loss of sucrose in the wash water.

Research Institute of chemical technology in Lodges (Poland) showed that the results obtained by the proposed method the sugar contains much less foreign matter and colour, ash content and other characteristics meet the European standard.

Elektronarkon putrefactive bacteria by means of magnetic fields allows to dispense with the use of formalin, chlorine and other toxic substances used as disinfectants. The sugar is organic, and it allows to increase the efficiency of the sugar factories more than 50 % (including beet cultivation on new technologies).

The application of magnetic spin waves special form of copyright certificate entitled “Apparatus for electro-anesthesia of the animals” No. 1148156 bull. No. 12 of 1962 the author Bolotov B. V., and the patent of Ukraine №0031773 from 15.12.2000 g "Method of darianna blogo cukru s tsukrovogo Buryak," the authors Bolotov, allows electro-anesthesia is not only animals, but also of putrefactive bacteria. Putrefactive bacteria under the action of impulsebuying fields inhibit their functional steps and fall into spaccone a few days.

16 years of experience in research and 14 years experience of a group of academician Bolotov in sugar factories of Ukraine clearly convinced not only of the feasibility but also the necessity of the use of energy-methods in sugar production as an alternative approach to the solution of many urgent problems such as the preservation of beets, loss of production, increased scale formation on the heating surfaces, the unevenness of crystallization, product quality, environment in production and in the region, the competitiveness of products by price, quality.

Fifty four million eight hundred seven thousand eight hundred six

Help :

Bolotov Boris scientist, chemist, physicist, biologist, broad horizons, the author of more than 600 inventions, many of which are introduced in the workplace, including abroad. First held reversible nuclear reaction for the decay of molybdenum electric current for niobium and technetium

$ 32 billion to the poor: such a large donation the world has ever seen

How to buy organic products

Sugar Bolotov has already won its admirers. Ukraine imported 5% of sugar, produced without the use of harmful substances. This sugar is bought baby food and the production of some medicines. Only two plants in Ukraine use this technology: starinsky and Novo-Ivanovo (data for 2006).

The use of this technology and the use of products manufactured in accordance with its regulations has the permission of the sanitary-epidemiological stations and the research Institute of toxicology. published

Source: www.facebook.com/notes/%D0%BD%D0%B0%D1%82%D0%B0%D0%BB%D1%8C%D1%8F-%D0%BB%D0%B5%D0%B2%D1%87%D0%B5%D0%BD%D0%BA%D0%BE/%D1%87%D1%82%D0%BE-%D1%82%D0%B0%D0%BA%D0%BE%D0%B5-%D1%81%D0%B0%D1%85%D0%B0%D1%80-%D0%B1%D0%BE%D0%BB%D0%BE%D1%82%D0%BE%D0%B2%D0%B0/10

Sugar - household name sucrose (C12H22O11) is an important food product. Regular sugar (sucrose) refers to carbohydrates that are considered valuable nutrients that provide the body with the necessary energy. Sugar can be obtained in different ways: from oil, gas, wood, etc. But the most cost-effective way of getting a sugar processing beet and a special type of cane, that is called the sugar — cane.

Thirty three million four hundred sixty four thousand eight hundred eighty

How to produce sugar

Sugar production from sugar beet is a traditional sector of the food industry of Ukraine. Sugar beet is a bulky and perishable product, so the factories for its processing are usually built close to plantations.

The technological process of production of beet sugar comprises the following stages:

- extractions;

- peeling;

- evaporations;

- crystallizations.

Extraction. First the beets are washed, then cut into chips, which are loaded into the diffuser where the sugar is extracted from plant material with hot water. The result is a "diffusion juice" containing 10 to 15% sucrose.

Cleaning. The diffusion juice is mixed in a saturator with milk of lime. In this case heavy impurities are deposited. Then through the heated solution is passed carbon dioxide to lime tied Asahara. Filtering, get the so-called"purified juice." Whitening includes passing sulfur dioxide through it, and then filtration through activated charcoal.

Evaporation. Excess water is removed by evaporation. Received eventually the liquid contains from 50 to 65% sugar.

Crystallization. The crystallization is carried out in a huge vacuum vessel with a height of sometimes six-bedroom house. Product of crystallization, the massecuite is a mixture of molasses with sucrose crystals. These components are separated by centrifugation, and the resulting solid dried sugar.

In the production of sugar by conventional techniques used disinfectants: formaldehyde, bleach, poisons amine group (basin, ambisol, as well as combinations of the above substances), hydrogen peroxide and others. Disinfectants are used to kill the microflora in a sugar solution, to disinfect the water coming into production.

Toxic effect of toxic substances is caused by the reactions of compounds of toxins with organic molecules with the formation of complex substances more toxic than the original. For example, bleach or bleach(CaCl2О) in the interaction in the water molecule amines to form Dioxins. The toxicity of Dioxins is higher chlorine toxicity 107 times, 67 times higher than the toxicity of potassium Cyanide and 500 times higher than the rat poison Strychnine.

Formaldehyde is a mutagen, carcinogen and is prohibited in use in contact with food. So our sugar annually receive temporary permits for the use of these substances in the food industry. Upon contact with the sucrose to 11% connected with formaldehyde, and part of this compound remains in the Sahara.

By evaporation to reduce the scale in the sugar syrup add antiscales (chelators of the type Antiplex). The complex molecule captures an ion of calcium, magnesium, etc., neutralizing the positive charge. As a result, this molecule does not stick to the heating surface, but remains in solution and accumulates in the sugar and molasses. And sugar comes to us in the body.

In the human body the chelating agent easily enters the bloodstream and accumulates in the thin capillaries. If vasoconstriction of the capillary, the probability of blockage increases dramatically (thrombosis). The consequences of thrombosis in the human body, especially in the human brain, known stroke.

In addition, to reduce surface tension of viscous solutions surfactants are used (detergent — sodium phosphate). To reduce foam are also used defoamers, flocculants — substances which increase the deposition of suspended particles.

To get white, clean and refined sugar, it must pass through the filter of cow bones. For the production of refined sugar beef bone char is used.

Fifty four million five hundred thirty six thousand three hundred fifty four

Than sugar Bolotov different from the usual

A group of academician Bolotov B. V. developed the complex of measures allowing to completely eliminate the use of chemicals in the production of sugar.

For cleaning sugar group of academician Bolotov used method of energy-information processes for the decontamination of bacterial environments and to combat the putrefactive processes to accelerate crystallization and reduce scale formation.

The application of the alternating magnetic field affects an offset of the response to Ca2+ and in the existing technology allows to reduce the use of milk of lime (calcium saharat three) that the end result reduces the content of calcium salts in purified sulphited juice.

On the other hand use alternating magnetic fields, accelerates sugar crystallization, improves the quality of the crystal mass, the yield of sucrose is increased; a decrease in the content of sucrose in molasses, “flour”, small crystal, reduces the loss of sucrose in the wash water.

Research Institute of chemical technology in Lodges (Poland) showed that the results obtained by the proposed method the sugar contains much less foreign matter and colour, ash content and other characteristics meet the European standard.

Elektronarkon putrefactive bacteria by means of magnetic fields allows to dispense with the use of formalin, chlorine and other toxic substances used as disinfectants. The sugar is organic, and it allows to increase the efficiency of the sugar factories more than 50 % (including beet cultivation on new technologies).

The application of magnetic spin waves special form of copyright certificate entitled “Apparatus for electro-anesthesia of the animals” No. 1148156 bull. No. 12 of 1962 the author Bolotov B. V., and the patent of Ukraine №0031773 from 15.12.2000 g "Method of darianna blogo cukru s tsukrovogo Buryak," the authors Bolotov, allows electro-anesthesia is not only animals, but also of putrefactive bacteria. Putrefactive bacteria under the action of impulsebuying fields inhibit their functional steps and fall into spaccone a few days.

16 years of experience in research and 14 years experience of a group of academician Bolotov in sugar factories of Ukraine clearly convinced not only of the feasibility but also the necessity of the use of energy-methods in sugar production as an alternative approach to the solution of many urgent problems such as the preservation of beets, loss of production, increased scale formation on the heating surfaces, the unevenness of crystallization, product quality, environment in production and in the region, the competitiveness of products by price, quality.

Fifty four million eight hundred seven thousand eight hundred six

Help :

Bolotov Boris scientist, chemist, physicist, biologist, broad horizons, the author of more than 600 inventions, many of which are introduced in the workplace, including abroad. First held reversible nuclear reaction for the decay of molybdenum electric current for niobium and technetium

$ 32 billion to the poor: such a large donation the world has ever seen

How to buy organic products

Sugar Bolotov has already won its admirers. Ukraine imported 5% of sugar, produced without the use of harmful substances. This sugar is bought baby food and the production of some medicines. Only two plants in Ukraine use this technology: starinsky and Novo-Ivanovo (data for 2006).

The use of this technology and the use of products manufactured in accordance with its regulations has the permission of the sanitary-epidemiological stations and the research Institute of toxicology. published

Source: www.facebook.com/notes/%D0%BD%D0%B0%D1%82%D0%B0%D0%BB%D1%8C%D1%8F-%D0%BB%D0%B5%D0%B2%D1%87%D0%B5%D0%BD%D0%BA%D0%BE/%D1%87%D1%82%D0%BE-%D1%82%D0%B0%D0%BA%D0%BE%D0%B5-%D1%81%D0%B0%D1%85%D0%B0%D1%80-%D0%B1%D0%BE%D0%BB%D0%BE%D1%82%D0%BE%D0%B2%D0%B0/10