516

Intelligent garbage sorting machine

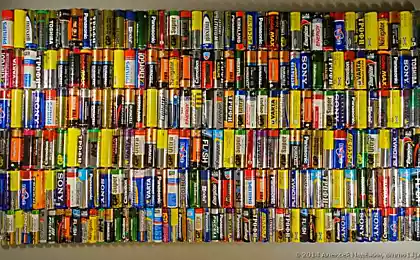

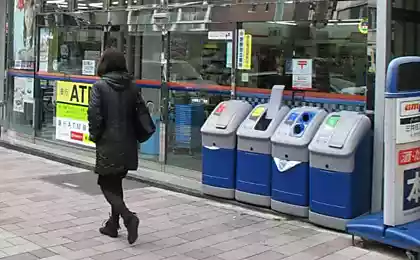

Harmless little battery actually carries a potential danger. It contains a lot of harmful for nature and human substances. The collection of used chemical current sources only the first step to security. The collected waste is received in the processing, which starts with sorting. Research scientists from the University of Gothenburg and University of Technology of Chalmers, Sweden, have allowed us to develop a machine for sorting batteries, using the elements of artificial intelligence.

Inventor – Klas Strannegard (Claes Strannegård), working in both academic institutions. The idea to create a sorting machine went to his head when the scientist was engaged in laying out different packages household waste. "The idea came to me at home when I've sorted the garbage. I thought I should be able to do this automatically with the involvement of artificial intelligence", — said the scientist.

Stranahan contacted the company Renova engaged in processing of garbage in Gothenburg and received a positive conclusion on the project of automatic sorting of collected for recycling batteries. The result of the collaboration and was a great machine.

The machine uses the algorithms of neural networks, which can be regarded as an artificial nervous system. As well as the human brain, neural networks can be trained to perform the required steps.

In this case, the machine was trained to recognise about 2,000 different types of batteries, "acquainted" with their pictures from different angles.

Battery serves the car on a "visual inspection" of a belt conveyor. The machine "sees" them with the camera, and within a few milliseconds will determine the type, comparing appearance with exemplary images uploaded in advance. Moreover, the car is able to learn to recognize contaminated or worn battery.

Identified battery with a compressed air jet directed at various containers in compliance with chemical composition, for example in containers for collection of waste Nickel or lithium. Per second the machine can process up to 10 batteries.

"Each battery system stores and provides information like brand and model. It allows you to determine exactly what types of materials we are able to offer the market after the disposal," says Hans-Eric Melin (Hans-Eric Melin), head of Optisort, the manufacturer of the machine.

This means that in addition to environmental benefits, the use of machines can bring commercial benefit. Yet companies pay money to the processors and collectors, to get rid of waste. But according to Melina, the availability of accurate data can cause the emergence of a new market segment. Perhaps in the near future sorted waste batteries will be bought and sold.

Currently Optisort has manufactured and supplied two cars. One of them in the company Renova sorts half of all batteries collected in Sweden. Another car bought by British firm G&P.

Source: /users/104

Inventor – Klas Strannegard (Claes Strannegård), working in both academic institutions. The idea to create a sorting machine went to his head when the scientist was engaged in laying out different packages household waste. "The idea came to me at home when I've sorted the garbage. I thought I should be able to do this automatically with the involvement of artificial intelligence", — said the scientist.

Stranahan contacted the company Renova engaged in processing of garbage in Gothenburg and received a positive conclusion on the project of automatic sorting of collected for recycling batteries. The result of the collaboration and was a great machine.

The machine uses the algorithms of neural networks, which can be regarded as an artificial nervous system. As well as the human brain, neural networks can be trained to perform the required steps.

In this case, the machine was trained to recognise about 2,000 different types of batteries, "acquainted" with their pictures from different angles.

Battery serves the car on a "visual inspection" of a belt conveyor. The machine "sees" them with the camera, and within a few milliseconds will determine the type, comparing appearance with exemplary images uploaded in advance. Moreover, the car is able to learn to recognize contaminated or worn battery.

Identified battery with a compressed air jet directed at various containers in compliance with chemical composition, for example in containers for collection of waste Nickel or lithium. Per second the machine can process up to 10 batteries.

"Each battery system stores and provides information like brand and model. It allows you to determine exactly what types of materials we are able to offer the market after the disposal," says Hans-Eric Melin (Hans-Eric Melin), head of Optisort, the manufacturer of the machine.

This means that in addition to environmental benefits, the use of machines can bring commercial benefit. Yet companies pay money to the processors and collectors, to get rid of waste. But according to Melina, the availability of accurate data can cause the emergence of a new market segment. Perhaps in the near future sorted waste batteries will be bought and sold.

Currently Optisort has manufactured and supplied two cars. One of them in the company Renova sorts half of all batteries collected in Sweden. Another car bought by British firm G&P.

Source: /users/104