491

Safety of batteries in electric cars

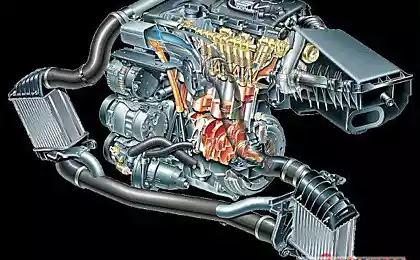

Nowadays there is renewed interest in lowering the environmental pollution. In addition to renewable power, which should act as a replacement of traditional energy, considering various options for the replacement of automotive internal combustion engines, which are sources of local pollution. However, if this is such a good idea, if you look at the situation from the point of view of security?

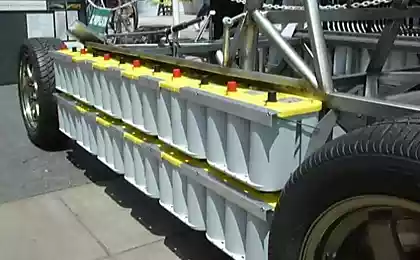

Currently, the trucking industry most often uses one of these three technologies batteries: supercapacitors, lithium-ion batteries and lead-acid batteries. The best of them in terms of "mass/energy" are lithium-ion batteries.

The theoretical voltage limit of the modern block format 18650 4.2 V, however the battery can not use it. The fact that during the lowering below the safe level, it turns out the so-called plating lithium (lithium plating). In other words, the conductive areas are formed of lithium, and this causes internal short circuit and thermal runaway of the battery (thermal runaway). This situation may also be formed after the strong temperature drop. The excess voltage causes thermal instability of the cell, which also leads to its destruction.

In the end, it is necessary to limit tension on top and bottom, including for the reason that the production has some variation in characteristics. The most safe are the batteries with LiFePO4 and LTO electrodes with cell voltages of 2.1, but here for safety need to pay a reduced voltage, and hence the available amount of energy in half.

The second major issue is the impact resistance of batteries, because it is impossible to exclude the possibility of an accident. Alas, the destruction of these types of batteries there is often a fire that can be extinguished only using non-lethal weapons. If the sample is lithium-ion batteries 18650 form-factor highlight, the auto-ignition occurs in 80% of cases. And in Tesla more than 6,000 such batteries!

The third problem, which at the moment there is no solution, is the quality of the production of batteries. Moreover, problems may arise regardless of the use, is sufficient to prevent the ingress of foreign bodies in the battery. The most striking examples, showing the problems of lithium-ion batteries, the cases of Dell and Boeing 787. In the first case they are simply replaced by similar.

On the second should tell us more. Boeing was a pioneer in applying lithium-ion batteries in aviation. Their aircraft used the battery larger than the standard. In January, 2013 thermal runaway caused the explosion, causing all the planes have lost the license to operate. After it was announced the solution to the problem, the aircraft was again allowed to fly in April 2013. But in January 2014 there was an ignition of the battery.

The "solution" Boeing was that the battery was installed in a reinforced compartment, thereby emerging with the battery problem didn't affect the rest of the plane. However, the problem was never resolved, because at this stage of technological development it is physically impossible. It should be noted that due to problems in the production of batteries, there have now been three Tesla car fires.

From all this we can conclude that to date, the reliability of the batteries is insufficient to battery mass used. In the short term, they will still be an expensive alternative, but over time their number will increase thanks to cheaper production. And if justified the most pessimistic scenario, the question of safety of operation of this car will be placed on the shoulders of the owner.

In General, the safety of batteries is a very important factor, which does not forget even those who use their mobile phones and laptops. It is likely that without the development of the industry and their introduction into the transport, these issues would not be raised so sharply.

Source: alternativenergy.ru

The construction of the “Vertical Forest” is completed in Milan

Ural scientists develop new technologies of water purification and recycling