585

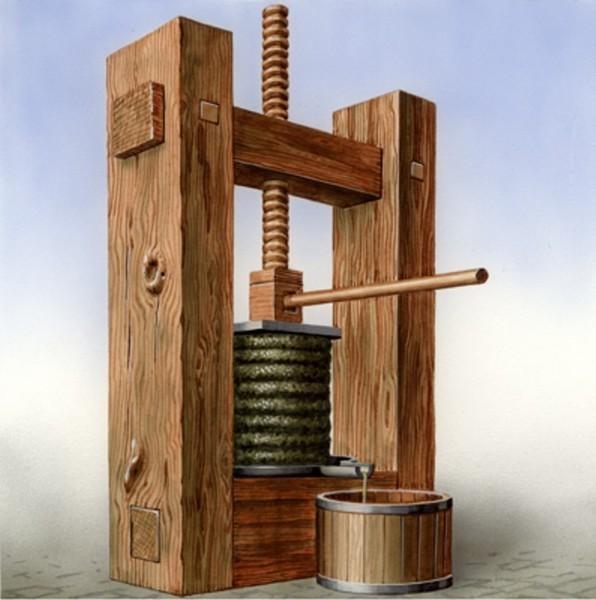

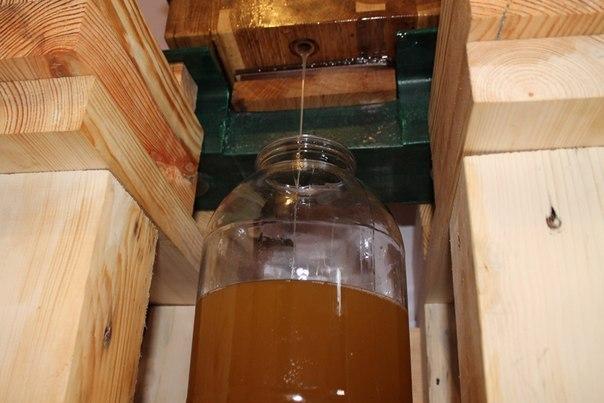

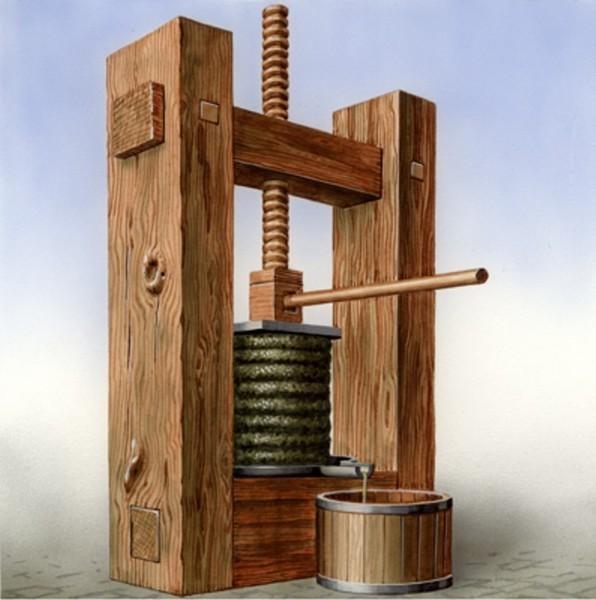

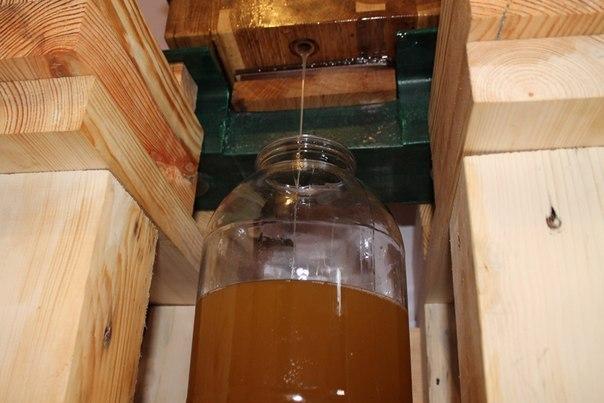

Home press for squeezing oil

To get the oil industrially, seeds pour gasoline fractions. Hexane, for example. When seeds are formed the oil, this hexane is removed with the help of water vapor, and its remnants are cleaned with lye. Output in the finished product there are different undesirable substances: resins and pigments. Solvent residues are rarely completely evaporated.

Before obtained by the extraction of oil can be eaten or used in medicine, it needs to pass several stages of purification: refining, then hydration, then whitening, after – deodorization and finally a couple more steps of filtration.

On hearing the phrase about oils that are 7 stages of filtration. It's true! Extraction oil can be endlessly clean, filter, purify, filter – to get rid of chemical gas components.

What happens in the end?

Product without any signs of life: without a single color and with a complete lack of any smell. The resulting slurry is bottled, and all the labels proudly write "oil", introducing all buyers in the delusion that it is.

Interestingly, in Russian supermarkets, for example, that of refined oil a year sold more than the number of seeds grown in Russia and the CIS! How is this possible? Using cheap palm oil, which diluted the already deodorized, refined and chemically processed oils.

Now I understand why vegetable oil HARMFUL?

Because it is impossible, even with the long and high-quality treatment, remove the remains of chemicals and gasoline – they will be present in the finished product. Besides the refined oil is subjected to heat treatment and chemicals, in contrast to the natural, very low content of vitamins, proteins, phosphatides, chlorophyll and carotene. Its composition is saturated fats and is very different from what was" originally nature.

We then eat! Fry meals in butter with petrol! But few people know that during high-temperature chemical reactions occur, resulting in the formation of a new, extremely toxic compounds. Therefore, the oil in any case can not be heated over 150 degrees or to use them again! But in the pan it reaches a temperature as 250 degrees!!!

Throughout life we are absolutely not thinking used is highly toxic a miracle food, and even gasoline, and then are surprised with his unexpected illness and poor health. Resent, as people at an early age sick with cancer and age faster than ever before...

What to do?

And you need to do your maslodelno, good nothing complicated here.

Mini maslodayna ensures the production of quality oil, which lasts for 1-2 years. It is possible to obtain oil from sunflower, rice, hemp, flax, pumpkin seed, watermelon, melon, and nuts.

Once in hardware stores sold mechanical press pressure grape or Apple juice, some of them provided the pressure to 12 atmospheres. To adapt them to the pressure the oil is very simple: you only need to replace the clip on a more powerful.

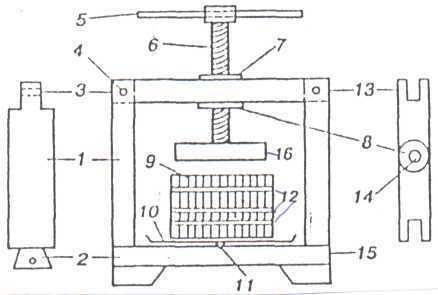

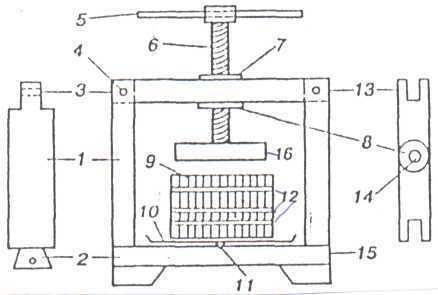

If you purchase this press failed, then it can be made from scrap materials. The design provides pressure on the mass by means of a worm screw. The pressure force depends on the power of struts beams, and the diameter of the worm nut. Therefore, the beam better to do with a large reserve of power, that is, the thickness and width of solid wood, or to look metal.

In design, there is a cylinder without a bottom. It can be made again or to make part of the barrel, preferably new with a rectilinear riveting, reinforced bottom another Hoop. Press the circle made of solid wood: oak, beech, ash, acacia. The material must be dry. Of the same material, it is desirable to make all other wooden parts of the structure. If you use a metal pan, hoops, flange), it is desirable to use a stainless metal or bronze.

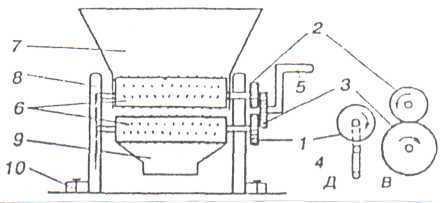

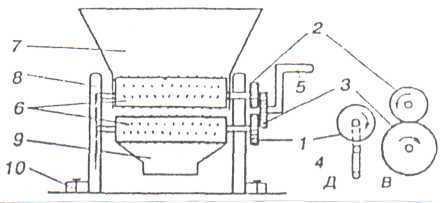

On maslodelnyi enterprises operations Stripping the husks and crushing the kernel executed separately. Here they managed to combine in one design, which is easy to manufacture.

Flour roller mills – two interchangeable rollers which rotate with the gears mounted on metal risers, which is also attached the upper and lower scoops, rocker lever or handle rotation. All these details can make or pick up from scrap. Replacement cushions wood lined cloth floats (depending on the width of the bolster need one or two floats, which are shredded potatoes for starch, or potato pancakes).

The process of operation is as follows: when filled the bucket of seeds to peel from the husk, from the working gear 3 rotates the gear 2, and from them rotates the upper roller, sheathed blade of a grater. Fixed with a lever and spring to the work gear 3, the reversible gear 1, which is included with it engages and rotates the other roller (lower), sheathed blade of a grater. The direction of movement — rotation. The seeds which are fed into the gap between the rollers, to peel. The kernel and the husk fall into the bottom bucket.

This mixture is collected, winnowed, and by replacing rollers on a smooth, fall asleep again in the top bucket. Now for the rolling. But in order to design tereminal mass, the lever must be in position In order to bring out of engagement the pinion 1, which will now be free to rotate in the same direction as gear 2, squeezing and peredelyvala -. Profilirovannaja mass in the form of a slurry, goes on pressing and squeezing oil.

As flour rolls and press separately work excellently. The products have clean, quality, delicious, especially when well-toasted. To do this, frankly, you need experience (all of this is achieved experimentally). The yield is somewhat lower than at specialized enterprises. And it is clear the pressure. But it is said to be bad.

Insufficiently stamped the cake (cake), if the engine is well cleaned, can be successfully used for making candy, cookies and other sweets.

And the oil comes out high quality. In addition, it is possible to mechanize the installation, supply the motors. To make several different types of plants and open home oil processing mini-plant, etc.

It all depends on your ingenuity.published

P. S. And remember, only by changing their consumption — together we change the world! ©

Join us in Facebook , Vkontakte, Odnoklassniki

Source: vk.com/pervorod?w=wall-48124846_32060

Before obtained by the extraction of oil can be eaten or used in medicine, it needs to pass several stages of purification: refining, then hydration, then whitening, after – deodorization and finally a couple more steps of filtration.

On hearing the phrase about oils that are 7 stages of filtration. It's true! Extraction oil can be endlessly clean, filter, purify, filter – to get rid of chemical gas components.

What happens in the end?

Product without any signs of life: without a single color and with a complete lack of any smell. The resulting slurry is bottled, and all the labels proudly write "oil", introducing all buyers in the delusion that it is.

Interestingly, in Russian supermarkets, for example, that of refined oil a year sold more than the number of seeds grown in Russia and the CIS! How is this possible? Using cheap palm oil, which diluted the already deodorized, refined and chemically processed oils.

Now I understand why vegetable oil HARMFUL?

Because it is impossible, even with the long and high-quality treatment, remove the remains of chemicals and gasoline – they will be present in the finished product. Besides the refined oil is subjected to heat treatment and chemicals, in contrast to the natural, very low content of vitamins, proteins, phosphatides, chlorophyll and carotene. Its composition is saturated fats and is very different from what was" originally nature.

We then eat! Fry meals in butter with petrol! But few people know that during high-temperature chemical reactions occur, resulting in the formation of a new, extremely toxic compounds. Therefore, the oil in any case can not be heated over 150 degrees or to use them again! But in the pan it reaches a temperature as 250 degrees!!!

Throughout life we are absolutely not thinking used is highly toxic a miracle food, and even gasoline, and then are surprised with his unexpected illness and poor health. Resent, as people at an early age sick with cancer and age faster than ever before...

What to do?

And you need to do your maslodelno, good nothing complicated here.

Mini maslodayna ensures the production of quality oil, which lasts for 1-2 years. It is possible to obtain oil from sunflower, rice, hemp, flax, pumpkin seed, watermelon, melon, and nuts.

Once in hardware stores sold mechanical press pressure grape or Apple juice, some of them provided the pressure to 12 atmospheres. To adapt them to the pressure the oil is very simple: you only need to replace the clip on a more powerful.

If you purchase this press failed, then it can be made from scrap materials. The design provides pressure on the mass by means of a worm screw. The pressure force depends on the power of struts beams, and the diameter of the worm nut. Therefore, the beam better to do with a large reserve of power, that is, the thickness and width of solid wood, or to look metal.

In design, there is a cylinder without a bottom. It can be made again or to make part of the barrel, preferably new with a rectilinear riveting, reinforced bottom another Hoop. Press the circle made of solid wood: oak, beech, ash, acacia. The material must be dry. Of the same material, it is desirable to make all other wooden parts of the structure. If you use a metal pan, hoops, flange), it is desirable to use a stainless metal or bronze.

On maslodelnyi enterprises operations Stripping the husks and crushing the kernel executed separately. Here they managed to combine in one design, which is easy to manufacture.

Flour roller mills – two interchangeable rollers which rotate with the gears mounted on metal risers, which is also attached the upper and lower scoops, rocker lever or handle rotation. All these details can make or pick up from scrap. Replacement cushions wood lined cloth floats (depending on the width of the bolster need one or two floats, which are shredded potatoes for starch, or potato pancakes).

The process of operation is as follows: when filled the bucket of seeds to peel from the husk, from the working gear 3 rotates the gear 2, and from them rotates the upper roller, sheathed blade of a grater. Fixed with a lever and spring to the work gear 3, the reversible gear 1, which is included with it engages and rotates the other roller (lower), sheathed blade of a grater. The direction of movement — rotation. The seeds which are fed into the gap between the rollers, to peel. The kernel and the husk fall into the bottom bucket.

This mixture is collected, winnowed, and by replacing rollers on a smooth, fall asleep again in the top bucket. Now for the rolling. But in order to design tereminal mass, the lever must be in position In order to bring out of engagement the pinion 1, which will now be free to rotate in the same direction as gear 2, squeezing and peredelyvala -. Profilirovannaja mass in the form of a slurry, goes on pressing and squeezing oil.

As flour rolls and press separately work excellently. The products have clean, quality, delicious, especially when well-toasted. To do this, frankly, you need experience (all of this is achieved experimentally). The yield is somewhat lower than at specialized enterprises. And it is clear the pressure. But it is said to be bad.

Insufficiently stamped the cake (cake), if the engine is well cleaned, can be successfully used for making candy, cookies and other sweets.

And the oil comes out high quality. In addition, it is possible to mechanize the installation, supply the motors. To make several different types of plants and open home oil processing mini-plant, etc.

It all depends on your ingenuity.published

P. S. And remember, only by changing their consumption — together we change the world! ©

Join us in Facebook , Vkontakte, Odnoklassniki

Source: vk.com/pervorod?w=wall-48124846_32060