475

The system "warm ceiling" heating, or Vice versa

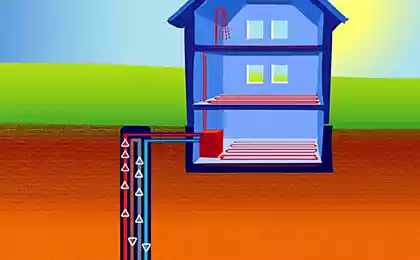

To combine in a single device system heating and cooling — a cherished dream of many owners of suburban real estate. It affects the versatility and usability of such a device. Despite the advantages of such a system, deters many of the high price and complexity of the mounting hardware that combines two functions. To reverse the situation decided by the Italian firm, which has developed a universal bar, heating the house in winter and cooling it in summer.

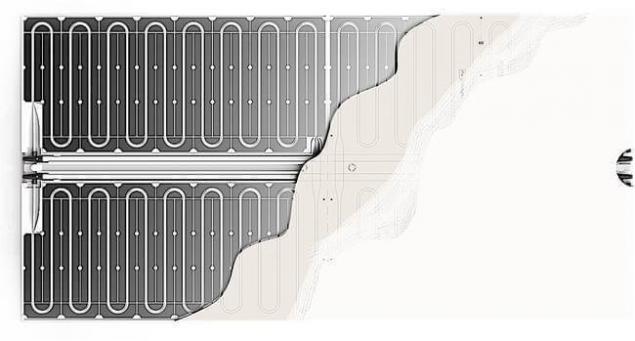

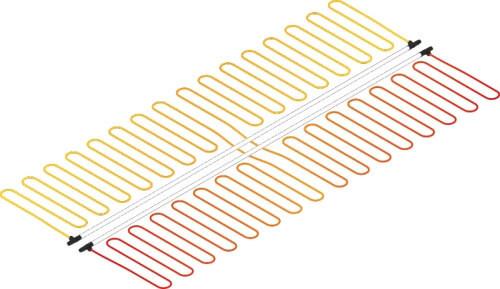

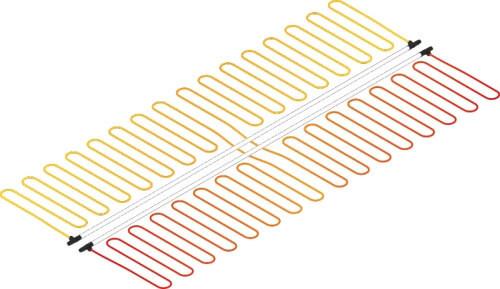

The company's engineers on the basis of a floor heating system, decided to get rid of such a technological stage as the screed. Instead, they constructed flat light panel thickness 2.5 cm, inside the box are tubes laid by a snake, which circulates the liquid.

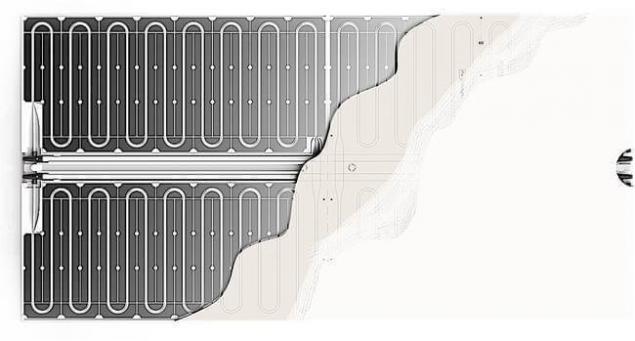

The heat panel is designed for flush mounting on the ceiling or in the wall, and the installation process is no more difficult than installing drywall sheets in the frame house.Patenting system, the Italians came out with his proposal for the North American market – the area where people traditionally prefer to heat the house air heating system.

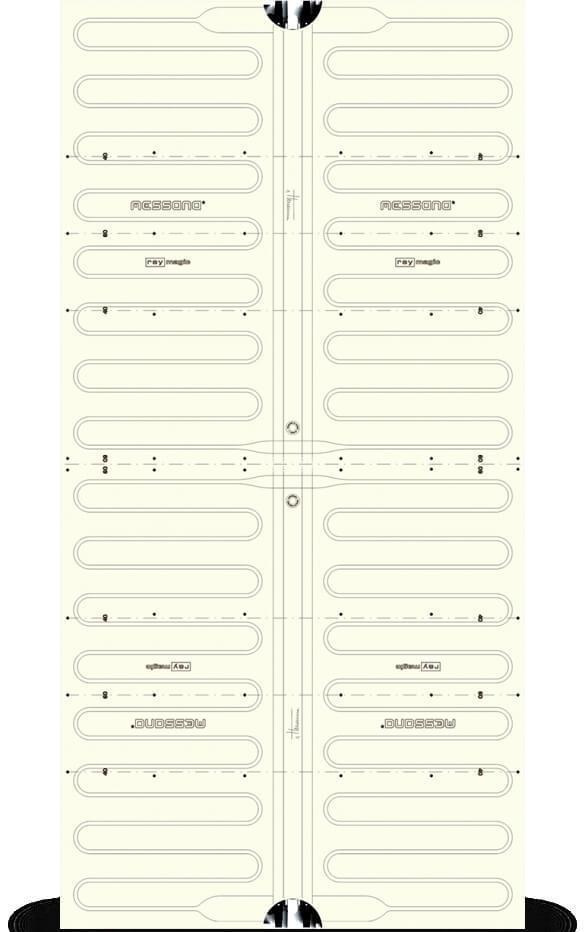

If we consider the panel in context, it is possible to see the bases made of foamed polystyrene. It is printed on a substrate of aluminum with progressirovanii grooves where stacked tube with two integrated fluidic circuits.

The top panel is closed standard sheet of drywall under the subsequent decorative finishes. Panels can be painted, glue them to the tiles, etc.

Depending on the season, tubing is fed hot or cold water. Accordingly, the system operates in heating or cooling.

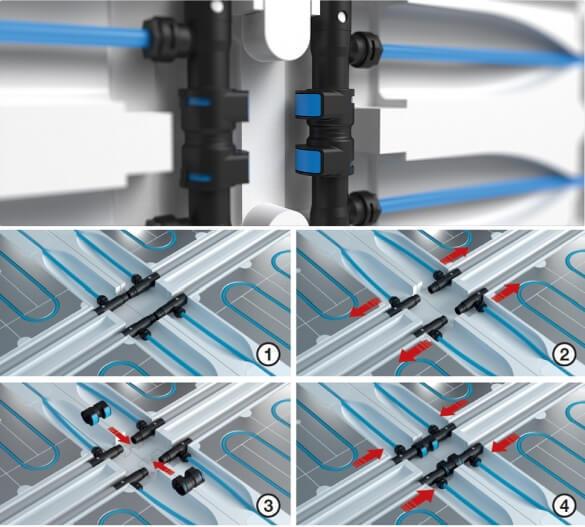

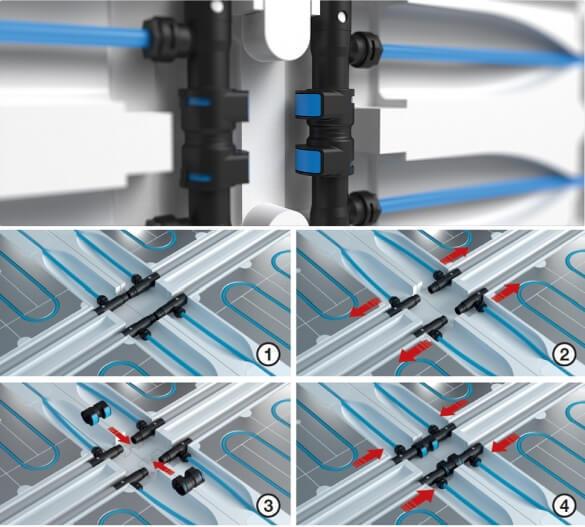

For ease of installation designers have developed a special adapter, which pipe can be quickly connected.

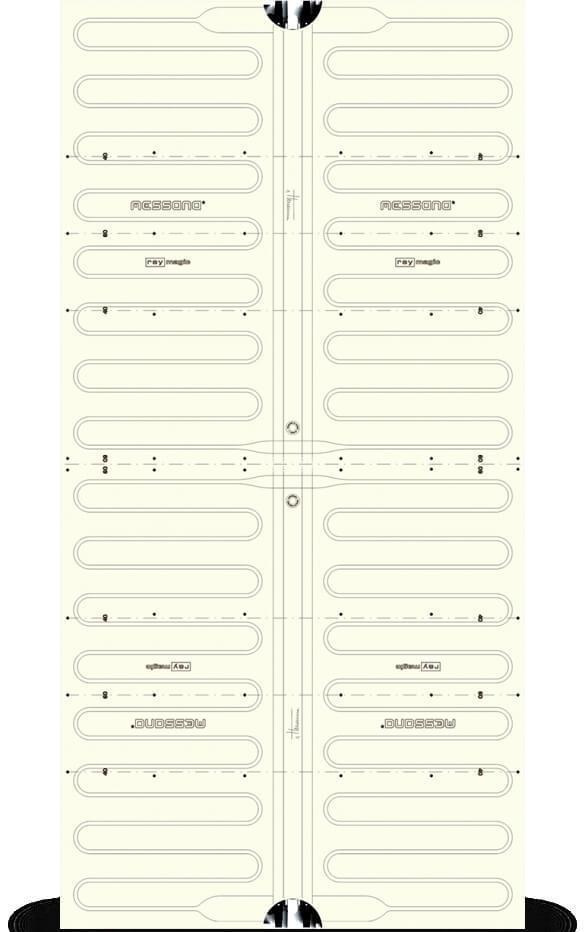

When installation work has not damaged pipework, with the outer side of plasterboard coated with a special markup, which marked the locations for screwing the screws. Also, the panels can be cut on marking lines, to connect with each other, increasing the area and power of the heating system.

Due to the modular build system and produced several sizes of the panels, greatly expanding the scope of the system.The authors emphasize that the system can be used both for heating private houses and large buildings, office type. Thanks to the good heat transfer, the panel quickly go to a specified thermal regime, but due to the small mass (in contrast to the system of floor and Foundation of ushp, which is especially important for karbasnikov) do not work as a heat accumulator.

For ease of management, developed a special system that includes a temperature sensor and a unit for regulating the temperature of the thermal panels. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: www.forumhouse.ru/articles/engineering-systems/6769

The company's engineers on the basis of a floor heating system, decided to get rid of such a technological stage as the screed. Instead, they constructed flat light panel thickness 2.5 cm, inside the box are tubes laid by a snake, which circulates the liquid.

The heat panel is designed for flush mounting on the ceiling or in the wall, and the installation process is no more difficult than installing drywall sheets in the frame house.Patenting system, the Italians came out with his proposal for the North American market – the area where people traditionally prefer to heat the house air heating system.

If we consider the panel in context, it is possible to see the bases made of foamed polystyrene. It is printed on a substrate of aluminum with progressirovanii grooves where stacked tube with two integrated fluidic circuits.

The top panel is closed standard sheet of drywall under the subsequent decorative finishes. Panels can be painted, glue them to the tiles, etc.

Depending on the season, tubing is fed hot or cold water. Accordingly, the system operates in heating or cooling.

For ease of installation designers have developed a special adapter, which pipe can be quickly connected.

When installation work has not damaged pipework, with the outer side of plasterboard coated with a special markup, which marked the locations for screwing the screws. Also, the panels can be cut on marking lines, to connect with each other, increasing the area and power of the heating system.

Due to the modular build system and produced several sizes of the panels, greatly expanding the scope of the system.The authors emphasize that the system can be used both for heating private houses and large buildings, office type. Thanks to the good heat transfer, the panel quickly go to a specified thermal regime, but due to the small mass (in contrast to the system of floor and Foundation of ushp, which is especially important for karbasnikov) do not work as a heat accumulator.

For ease of management, developed a special system that includes a temperature sensor and a unit for regulating the temperature of the thermal panels. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: www.forumhouse.ru/articles/engineering-systems/6769