1184

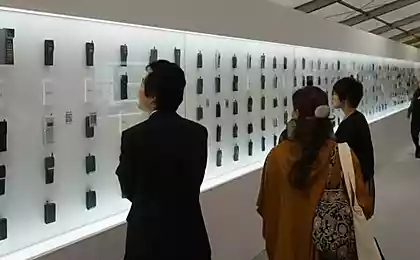

How to test mobile phones

In a quiet business park English town of Farnborough, engineer Kevin Smith every day engaged in one and the same thing: corruption cell phones.

"If we do not break it, consider that we have not done your job," says the man who occupied an unusual profession - deliberately damage telephone.

The main task of each working day Smith - help check handsets on the strength, and to figure out how to behave like machines in cases of force majeure.

"At the moment we practice about 200 different tests, and if we were to do one test after the other hand, that we would take about five years to get rid of the full cycle. Our tests allow you to check in the tube, everything from buttons and ending with the shutter of the camera, "Smith tells us, starting to talk about their work.

Of course, we do not need 5 years to test phones, but checking around 300-500 samples handsets at a time, we spend about 8 weeks (if they pass the test once). Saves a lot of time that the testing department works hand in hand with designers, in a building adjacent to the beginning of the project. Even when the new handset models are not yet in the material sense of the word, Kevin and his merry band of destroyers break material directly on a computer monitor, the program simulates the mechanical action.

"We check all factors, starting with the fall of the simulation of the tube with a small height and finishing simulation effects of extreme temperature and humidity," says Smith.

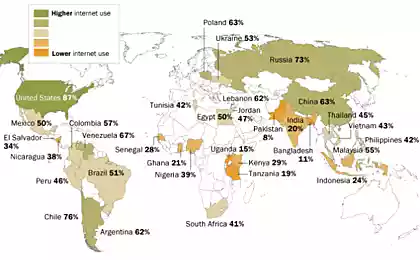

"Once we progonim these tests, we are fully confident that the customer can buy the phone in any country (with any climate) and take her to any point on the globe».

"If we do not break it, consider that we have not done your job," says the man who occupied an unusual profession - deliberately damage telephone.

The main task of each working day Smith - help check handsets on the strength, and to figure out how to behave like machines in cases of force majeure.

"At the moment we practice about 200 different tests, and if we were to do one test after the other hand, that we would take about five years to get rid of the full cycle. Our tests allow you to check in the tube, everything from buttons and ending with the shutter of the camera, "Smith tells us, starting to talk about their work.

Of course, we do not need 5 years to test phones, but checking around 300-500 samples handsets at a time, we spend about 8 weeks (if they pass the test once). Saves a lot of time that the testing department works hand in hand with designers, in a building adjacent to the beginning of the project. Even when the new handset models are not yet in the material sense of the word, Kevin and his merry band of destroyers break material directly on a computer monitor, the program simulates the mechanical action.

"We check all factors, starting with the fall of the simulation of the tube with a small height and finishing simulation effects of extreme temperature and humidity," says Smith.

"Once we progonim these tests, we are fully confident that the customer can buy the phone in any country (with any climate) and take her to any point on the globe».