1072

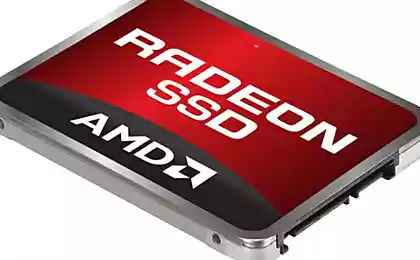

From silicon metal to SSD: how to create solid-state drives OCZ

Hello, Geektimes! Many users SSDs often wonder: how and where, in fact, produce a SSD? How difficult is this process? And if the general assembly of some of the principles are known, to look "behind the scenes" produced on forces far not for everyone. Today we'll show you how to create the SSD, and make a short trip to the OCZ factory in Taiwan.

Before you - the silicon metal. That it is the basis of chip production, including components for solid-state drives. Now it is often made carbothermic process which is patented by Russian scientists, using in the process of ore-thermal furnace. Ton is such a good two to three thousand euros. In large furnace plants produced on metallic silicon having a purity of 98, 5%, and silicon dust. The latter are used usually in the mortar, so that it is of little interest to us.

Technical silicon is obtained by reducing coke SiO2 melt temperature reaches 1800 with degrees Celsius. Thus produced silicon with a purity of 99% 9, where the rest - carbon and metals

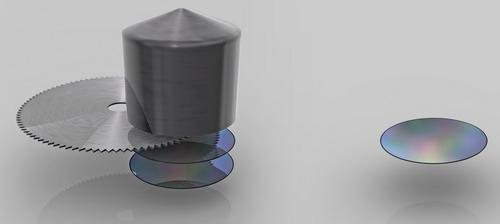

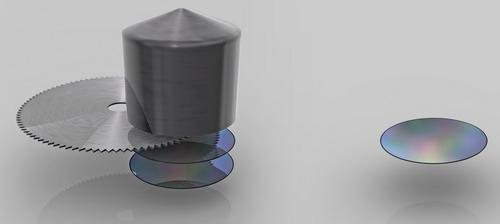

. But for the production of electronic components we need a so-called electronic silicon, "pure diamond" among silicon. Technical chlorinated silicon and trichlorosilane (SiHCl3). After his treatment at the outlet have an electronic silicon, in which the impurity concentration is very small - usually 0% 0000001. Electronic silicon melted in the single crystals, which are then cut into wafers and diamond saw.

Here is one such single crystal, which can weigh a hundredweight, and even more.

Schematically thread looks like a saw, believe me, is very urgent:

The wafers are polished and made smooth, so that they shone straight in the literal sense. But we will not go deeply into the intricacies of production, all the more so in the description of all the processes we simply do not have enough ink. To illustrate all this, in fact, better to look at the production of their own eyes. The plant OCZ.

Introduction and gist of the production process SSD

While our "plane" landed on Taiwan, let's first look at how to build solid-state drives in the production process of OCZ. Before the drive will be in a factory for the assembly of its design, say the design, test, create a set of concepts. The chart below clearly shows the main stages of the design process.

As with any product, SSD development starts with the idea that may not necessarily represent an entirely new storage model. It can be updated with the new current line of NAND, its completion larger capacity version, another form factor, the new software and so on. At the zero point the idea is ready to become a concept, it is only a "nudge" in the right direction. This will help document, which usually consists of 1-2 pages, which contains a brief description of the product and the purpose of its creation.

Once the concept has settled, marketing and engineering teams join forces. Both are very important because the drive must not only sell, but also to be reliable and modern, combining the latest advances in the industry. Work takes about three weeks, and ends with the formation and description of the system requirements. If the latter fails to formulate the product returns to the concept stage.

In the second stage OCZ plans and allocates resources for the project, only then it begins work on its embodiment. Two important documents that are necessary for this - marketing requirements and engineering report. Generally, the second stage is one of the most important, because it requires concerted action teams and to work on all aspects and subtleties, including the budget. From a project plan and budget depends on where the company will direct its hundreds of thousands (if not millions) of dollars, so that the calculation can not be here. The second phase depends on the product and on the teams that are working on it: it usually takes one to three months (the last - in the case of the development of a completely new drive)

. If the budget for the project is selected, the OCZ moves on to the third phase, where most of the work of engineers has already been done. The main purpose - to create the first working prototype, so it can be tested.

At that time, engineers are busy with their work, the other teams perform their own tasks and prepare everything for the production of prototypes (at this stage, selected providers, developed the preliminary specifications and marketing materials). The length of the stages of development and realization largely depends on the product, but even the drive using an existing controller may be "stuck" on it for a year. The development of an entirely new controller (for example, JetExpress) and does take several years.

Quarter phase, which includes the analysis and quality evaluation consists of three main parts: an engineering Screening Test (EVT), design verification test (DVT) and production verification test (PVT)

.

EVT shows how the drive works in the real world, and whether it is consistent with what was written on paper. Set the parameters for the test relatively simple: the power level, response speed, otherwise make sure that the prototype works as planned.

DVT is divided into two phases: a "normal" test and the test quality / reliability. «Normal» DVT consists of a broader set of tests than the EVT, and shows how the drive behaves under different conditions. Each test is usually run at least four prototypes, while the EVT run on one or two. Generally, the DVT is an aggregator of dozens of different tests, including a test for compliance, shelf-life data, loss of power, and so on.

Why DVT consists of two parts? The fact that the EVT and "normal» DVT made engineering team (who also developed the design of the drive), so in the process of testing may be conflicts of interest and the human factor - people like to close their eyes to their own mistakes. Therefore, the quality / reliability of the test conducted by an independent team of quality control. These tests take much longer and are held on more devices than EVT.

Production screening test is required not only to test the reliability of the drive, how to check the production process. Simply put, the main goal of PVT - ensuring that each disc from the production line was a single (high) quality. For this purpose, any drive line is taken and inspected for various defects caused by soldering. PVT is also used to assess the quality of the factory system, even including inspection boxes. Then conducted another test (ORT), which checks multiple disks from different production lines.

The total duration of the test phase varies from two to six months, or even years. In the first case - if the disc structure is relatively simple and similar to the previous drives. While SSD has passed all stages of testing, he did not go to the next step, mass production will not start. Thus, consumers will not see it.

Welcome to manufacture!

After final tests PVT confirmed the conformity of the declared disk specifications. Once the stage is over, it begins mass production of SSD. Where is going the whole "magic»?

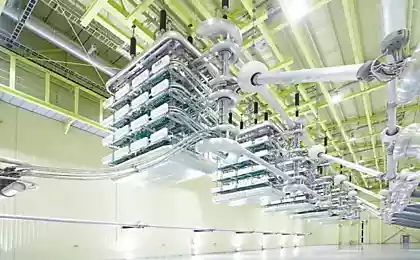

OCZ plant is located in Zhongli, Taoyuan district in the northwestern part of Taiwan, a 45-minute drive from Taipei. Formally, the factory is owned by Powertech - it was sold to the final after a deal with Toshiba. Powertech is a respected player in the manufacturing industry, which has contracts with many companies, including Apple. In addition, the company has built a good relationship with both the OCZ, and with Toshiba.

Two production lines of surface mount completely relate to OCZ and produce about 70 thousand units per month. If suddenly appears drives high demand, the company also uses other lines in the future, OCZ expects to increase production capacity. But let us see how, in fact, are assembled SSD.

Manufacturing SSD

Production SSD is virtually identical to the assembly of another component constructed on the PCB.

It begins with the production of the PCB (hello, "electronic" Si!), Which is coated chip using solder paste, a mixture of small particles of tin with flux. This occurs in the machine, which is shown in the photo above.

Solder paste should be stored at a temperature close to zero degrees Celsius, otherwise it will lose its adhesive properties. Therefore, it is stored in a small jar in the refrigerator.

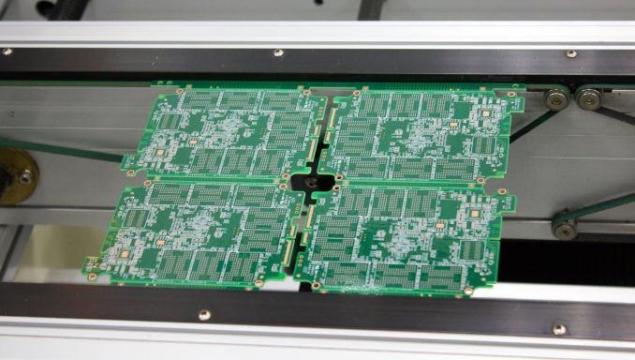

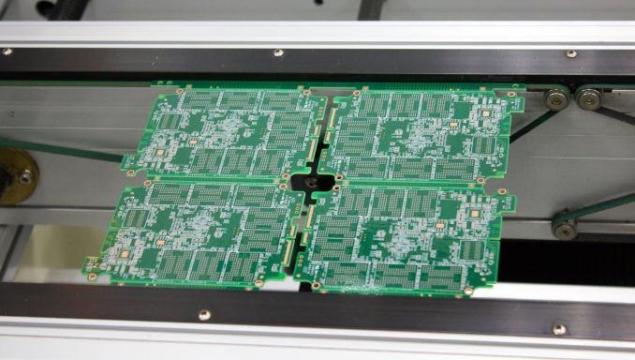

The finished board with chips can be seen in the photo below. At the same time it can be made four card form factor 2, 5 inches.

The PCB is ready to "accept" the chips, which are installed with the help of this machine. Each chip resistor and is loaded into the "tape and reel" machines, which automatically installs all of the components in the desired locations on the PCB.

Controllers are located in another tray - this is the last component that is mounted on a printed circuit board before the next step

.

Once all the components are assembled, the drive goes into a special "bake" the paste which melts and provides electrical connection between all chips. This process takes about five minutes, the temperature increased sharply at first and then, in the final stage, decreases. The exact temperature profile is unique and was designed by engineers of the OCZ, but sometimes it is necessary to adjust the - so to speak, by trial and error

.

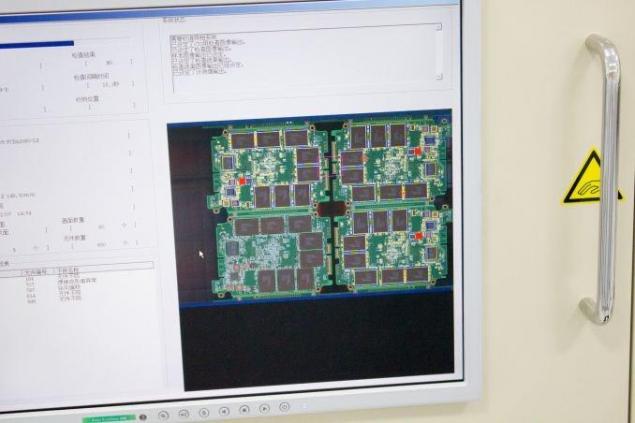

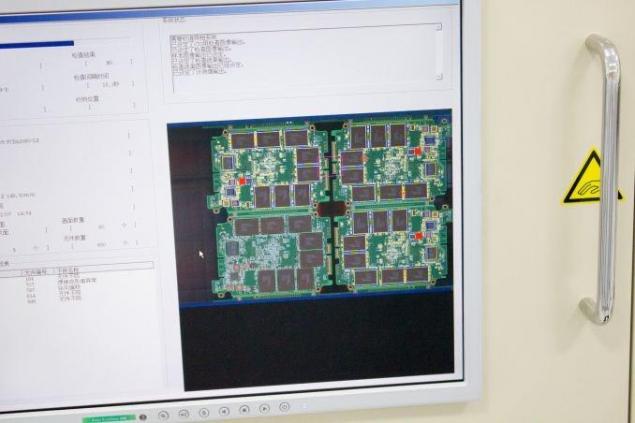

After melting the board receives an automatic visual inspection, where the product cost is compared with the image of the perfect dress - so, it is possible to avoid mistakes like improperly installed chips. Blindly rely on automation in the present case it is not necessary, so just in case, this step monitors the employee. For double-sided printed circuit boards the entire process from printing to visual inspection, respectively, is repeated, however a small capacity SSD generally used single-sided board. This reduces the costs and storage costs for the end user.

At the final stage of the charge is connected to the SATA connector and power supply. Sometimes the latter is integrated into the board, but often it is located separately. When this process is completed, the boards are cut and separated from the frame. Then it is placed in a metal casing and screwed screws - is responsible for it's such a unit:

Software Installation

When a part is finished at hardware, the software.

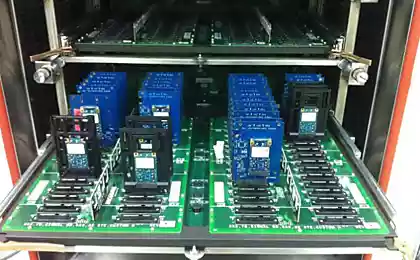

Download the firmware is performed by special computers with quite ordinary iron, as the Linux operating system is used with the installed utility software download from OCZ. In the picture above, for example, installed software for SSD ARC 100 with a capacity of 240 GB.

Once the firmware is downloaded, certainly drives again tested. OCZ has developed a special script which exposes the SSD read and write procedure at least eight times to identify bad blocks. In case of marriage or the drive is sent back for revision, or, as happens more often, he just destroyed. The scripts also test the performance, using tools for benchmarks, such as the AS-SSD and ATTO. It should in fact make sure that the SSD meets the stated specifications.

Now OCZ has two types of testing. In the first case it is conventional computers, we saw a little earlier, in the second - large cockpit with racks that at a time can check out 256 drives. The second option is preferable, and, and faster, but not always, they are able to take advantage of.

For storage PCIe OCZ has developed a more advanced form of testing - manufacturing self-diagnosis. On the SSD installed custom software performs read and write processes. In this case, everything happens faster, since all input-output commands generated by the controller, or firmware.

Furthermore, each of one month produced is sent to storage "Compliance test" to check the level of product quality. At this time, SSD is subjected to sudden changes in temperature, including up to 70 degrees Celsius. This makes it possible to measure the period of storage in extreme conditions of life - it should not differ from the declared

.

The testing process has not changed much since the deal with Toshiba, but it is worth noting that Toshiba still OCZ has helped establish quality standards. All processes which are subjected to the SSD, approved by the "parent" company and meet its requirements. Each drive follows a very strict, and it is certainly a positive impact on the quality of the SSD from OCZ. You yourself are convinced of this - the selection is almost like astronauts

Weather and packaging

.? Exactly how could we forget. Only if the SSD has successfully passed all tests, it meets the stated specifications, works flawlessly and without errors, it is ready to to go into the package. First to drive brand paste stickers - Now employees perform it manually, but very soon the process will be automated

.

Come quickly in the box! For SSD packaging in a nice cardboard box meets here this machine:

In the next phase drives and accessories are packed in plastic wrap - it is sealed under high temperature

.

The retail stores are sent in large boxes that can hold 10 drives at once. Black protects the substrate from falling SSD box or other external influence - this ensures that the store will reach stores intact. To check this, OCZ also hold a special drop-tests.

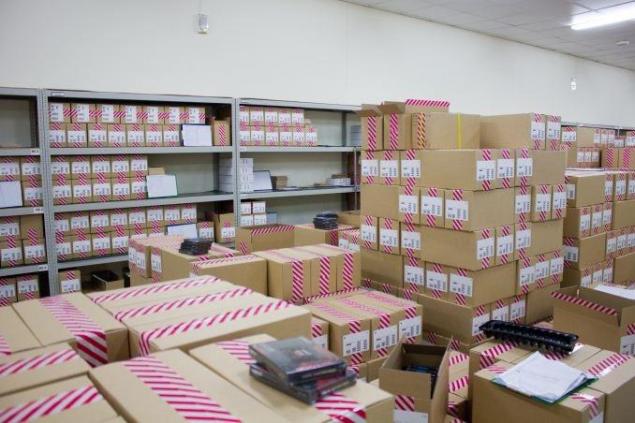

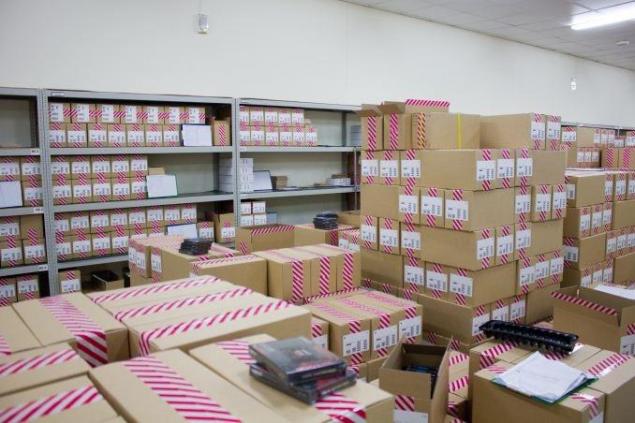

The boxes are sealed and sent to a temporary storage facility, where the SSD and then get on the shelves.

Instead of conclusion

Admittedly, the attitude to the quality of its OCZ drives completely changed. In the past it was unheard of that the device can "hang" for three months at the design stage, before entering into mass production. Now, however, the duration of the stages is increased to several times that the company was not ashamed of any of the one your drive. When it comes to quality, we have nothing to hide. Yet, from the silicon to the SSD path is not short, you saw it yourself. We hope it was interesting.

Source: geektimes.ru/company/ocz/blog/273978/

Before you - the silicon metal. That it is the basis of chip production, including components for solid-state drives. Now it is often made carbothermic process which is patented by Russian scientists, using in the process of ore-thermal furnace. Ton is such a good two to three thousand euros. In large furnace plants produced on metallic silicon having a purity of 98, 5%, and silicon dust. The latter are used usually in the mortar, so that it is of little interest to us.

Technical silicon is obtained by reducing coke SiO2 melt temperature reaches 1800 with degrees Celsius. Thus produced silicon with a purity of 99% 9, where the rest - carbon and metals

. But for the production of electronic components we need a so-called electronic silicon, "pure diamond" among silicon. Technical chlorinated silicon and trichlorosilane (SiHCl3). After his treatment at the outlet have an electronic silicon, in which the impurity concentration is very small - usually 0% 0000001. Electronic silicon melted in the single crystals, which are then cut into wafers and diamond saw.

Here is one such single crystal, which can weigh a hundredweight, and even more.

Schematically thread looks like a saw, believe me, is very urgent:

The wafers are polished and made smooth, so that they shone straight in the literal sense. But we will not go deeply into the intricacies of production, all the more so in the description of all the processes we simply do not have enough ink. To illustrate all this, in fact, better to look at the production of their own eyes. The plant OCZ.

Introduction and gist of the production process SSD

While our "plane" landed on Taiwan, let's first look at how to build solid-state drives in the production process of OCZ. Before the drive will be in a factory for the assembly of its design, say the design, test, create a set of concepts. The chart below clearly shows the main stages of the design process.

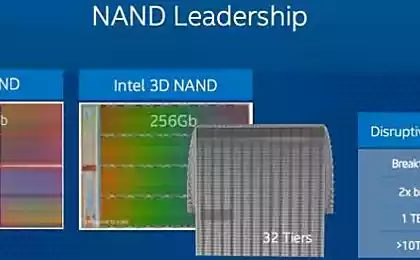

As with any product, SSD development starts with the idea that may not necessarily represent an entirely new storage model. It can be updated with the new current line of NAND, its completion larger capacity version, another form factor, the new software and so on. At the zero point the idea is ready to become a concept, it is only a "nudge" in the right direction. This will help document, which usually consists of 1-2 pages, which contains a brief description of the product and the purpose of its creation.

Once the concept has settled, marketing and engineering teams join forces. Both are very important because the drive must not only sell, but also to be reliable and modern, combining the latest advances in the industry. Work takes about three weeks, and ends with the formation and description of the system requirements. If the latter fails to formulate the product returns to the concept stage.

In the second stage OCZ plans and allocates resources for the project, only then it begins work on its embodiment. Two important documents that are necessary for this - marketing requirements and engineering report. Generally, the second stage is one of the most important, because it requires concerted action teams and to work on all aspects and subtleties, including the budget. From a project plan and budget depends on where the company will direct its hundreds of thousands (if not millions) of dollars, so that the calculation can not be here. The second phase depends on the product and on the teams that are working on it: it usually takes one to three months (the last - in the case of the development of a completely new drive)

. If the budget for the project is selected, the OCZ moves on to the third phase, where most of the work of engineers has already been done. The main purpose - to create the first working prototype, so it can be tested.

At that time, engineers are busy with their work, the other teams perform their own tasks and prepare everything for the production of prototypes (at this stage, selected providers, developed the preliminary specifications and marketing materials). The length of the stages of development and realization largely depends on the product, but even the drive using an existing controller may be "stuck" on it for a year. The development of an entirely new controller (for example, JetExpress) and does take several years.

Quarter phase, which includes the analysis and quality evaluation consists of three main parts: an engineering Screening Test (EVT), design verification test (DVT) and production verification test (PVT)

.

EVT shows how the drive works in the real world, and whether it is consistent with what was written on paper. Set the parameters for the test relatively simple: the power level, response speed, otherwise make sure that the prototype works as planned.

DVT is divided into two phases: a "normal" test and the test quality / reliability. «Normal» DVT consists of a broader set of tests than the EVT, and shows how the drive behaves under different conditions. Each test is usually run at least four prototypes, while the EVT run on one or two. Generally, the DVT is an aggregator of dozens of different tests, including a test for compliance, shelf-life data, loss of power, and so on.

Why DVT consists of two parts? The fact that the EVT and "normal» DVT made engineering team (who also developed the design of the drive), so in the process of testing may be conflicts of interest and the human factor - people like to close their eyes to their own mistakes. Therefore, the quality / reliability of the test conducted by an independent team of quality control. These tests take much longer and are held on more devices than EVT.

Production screening test is required not only to test the reliability of the drive, how to check the production process. Simply put, the main goal of PVT - ensuring that each disc from the production line was a single (high) quality. For this purpose, any drive line is taken and inspected for various defects caused by soldering. PVT is also used to assess the quality of the factory system, even including inspection boxes. Then conducted another test (ORT), which checks multiple disks from different production lines.

The total duration of the test phase varies from two to six months, or even years. In the first case - if the disc structure is relatively simple and similar to the previous drives. While SSD has passed all stages of testing, he did not go to the next step, mass production will not start. Thus, consumers will not see it.

Welcome to manufacture!

After final tests PVT confirmed the conformity of the declared disk specifications. Once the stage is over, it begins mass production of SSD. Where is going the whole "magic»?

OCZ plant is located in Zhongli, Taoyuan district in the northwestern part of Taiwan, a 45-minute drive from Taipei. Formally, the factory is owned by Powertech - it was sold to the final after a deal with Toshiba. Powertech is a respected player in the manufacturing industry, which has contracts with many companies, including Apple. In addition, the company has built a good relationship with both the OCZ, and with Toshiba.

Two production lines of surface mount completely relate to OCZ and produce about 70 thousand units per month. If suddenly appears drives high demand, the company also uses other lines in the future, OCZ expects to increase production capacity. But let us see how, in fact, are assembled SSD.

Manufacturing SSD

Production SSD is virtually identical to the assembly of another component constructed on the PCB.

It begins with the production of the PCB (hello, "electronic" Si!), Which is coated chip using solder paste, a mixture of small particles of tin with flux. This occurs in the machine, which is shown in the photo above.

Solder paste should be stored at a temperature close to zero degrees Celsius, otherwise it will lose its adhesive properties. Therefore, it is stored in a small jar in the refrigerator.

The finished board with chips can be seen in the photo below. At the same time it can be made four card form factor 2, 5 inches.

The PCB is ready to "accept" the chips, which are installed with the help of this machine. Each chip resistor and is loaded into the "tape and reel" machines, which automatically installs all of the components in the desired locations on the PCB.

Controllers are located in another tray - this is the last component that is mounted on a printed circuit board before the next step

.

Once all the components are assembled, the drive goes into a special "bake" the paste which melts and provides electrical connection between all chips. This process takes about five minutes, the temperature increased sharply at first and then, in the final stage, decreases. The exact temperature profile is unique and was designed by engineers of the OCZ, but sometimes it is necessary to adjust the - so to speak, by trial and error

.

After melting the board receives an automatic visual inspection, where the product cost is compared with the image of the perfect dress - so, it is possible to avoid mistakes like improperly installed chips. Blindly rely on automation in the present case it is not necessary, so just in case, this step monitors the employee. For double-sided printed circuit boards the entire process from printing to visual inspection, respectively, is repeated, however a small capacity SSD generally used single-sided board. This reduces the costs and storage costs for the end user.

At the final stage of the charge is connected to the SATA connector and power supply. Sometimes the latter is integrated into the board, but often it is located separately. When this process is completed, the boards are cut and separated from the frame. Then it is placed in a metal casing and screwed screws - is responsible for it's such a unit:

Software Installation

When a part is finished at hardware, the software.

Download the firmware is performed by special computers with quite ordinary iron, as the Linux operating system is used with the installed utility software download from OCZ. In the picture above, for example, installed software for SSD ARC 100 with a capacity of 240 GB.

Once the firmware is downloaded, certainly drives again tested. OCZ has developed a special script which exposes the SSD read and write procedure at least eight times to identify bad blocks. In case of marriage or the drive is sent back for revision, or, as happens more often, he just destroyed. The scripts also test the performance, using tools for benchmarks, such as the AS-SSD and ATTO. It should in fact make sure that the SSD meets the stated specifications.

Now OCZ has two types of testing. In the first case it is conventional computers, we saw a little earlier, in the second - large cockpit with racks that at a time can check out 256 drives. The second option is preferable, and, and faster, but not always, they are able to take advantage of.

For storage PCIe OCZ has developed a more advanced form of testing - manufacturing self-diagnosis. On the SSD installed custom software performs read and write processes. In this case, everything happens faster, since all input-output commands generated by the controller, or firmware.

Furthermore, each of one month produced is sent to storage "Compliance test" to check the level of product quality. At this time, SSD is subjected to sudden changes in temperature, including up to 70 degrees Celsius. This makes it possible to measure the period of storage in extreme conditions of life - it should not differ from the declared

.

The testing process has not changed much since the deal with Toshiba, but it is worth noting that Toshiba still OCZ has helped establish quality standards. All processes which are subjected to the SSD, approved by the "parent" company and meet its requirements. Each drive follows a very strict, and it is certainly a positive impact on the quality of the SSD from OCZ. You yourself are convinced of this - the selection is almost like astronauts

Weather and packaging

.? Exactly how could we forget. Only if the SSD has successfully passed all tests, it meets the stated specifications, works flawlessly and without errors, it is ready to to go into the package. First to drive brand paste stickers - Now employees perform it manually, but very soon the process will be automated

.

Come quickly in the box! For SSD packaging in a nice cardboard box meets here this machine:

In the next phase drives and accessories are packed in plastic wrap - it is sealed under high temperature

.

The retail stores are sent in large boxes that can hold 10 drives at once. Black protects the substrate from falling SSD box or other external influence - this ensures that the store will reach stores intact. To check this, OCZ also hold a special drop-tests.

The boxes are sealed and sent to a temporary storage facility, where the SSD and then get on the shelves.

Instead of conclusion

Admittedly, the attitude to the quality of its OCZ drives completely changed. In the past it was unheard of that the device can "hang" for three months at the design stage, before entering into mass production. Now, however, the duration of the stages is increased to several times that the company was not ashamed of any of the one your drive. When it comes to quality, we have nothing to hide. Yet, from the silicon to the SSD path is not short, you saw it yourself. We hope it was interesting.

Source: geektimes.ru/company/ocz/blog/273978/

Computer has written a new Rembrandt painting through the 347 years after his death

Samsung has filed a patent application smart contact lenses