1044

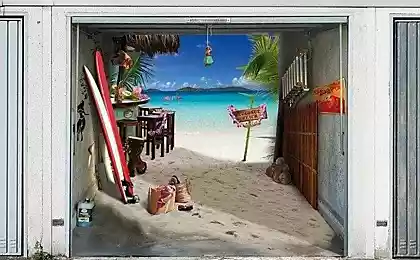

Cases garage

Today was held under the motto "One for all and all for one." Just yesterday or the day before, when sawed planks, once again cursed the wire. During sawing, using three tools: hand circular saw, jigsaw, and Bulgarian. So, the power cords of the three intrumentov time to get entangled in an hour of work.

38 photo.

Picture looked like this:

Last night, once again surf the Internet in search of interesting solutions for the storage of certain instruments and consumables for them, stumbled on this picture (then found the article author). Interesting idea, I thought. And instantly I have matured a similar idea. The decision on the picture is good, but the connectors are not fixed. In the process, anything can happen (I often step on the wire, for example). You had a decision to commit.

Wool began internet for various connectors and 5 minutes later came a second insight - Speakon! Spikony used in the professional concert environment, they connect the speakers to the amplifier. Meet - PowerCon!

Things are expensive, but they are his. Checked experience. I was not sure whether I can mount sockets inside the case of all instruments. In extreme cases, if not obtained, decided that I will do like the picture, which has found. So, the first patient, whom I decided to dissect - drill. Disassemble, see the following picture.

Try on the connector. Hmm, if slightly modify it, you can shove. We'll have two sides with little to choose plastic casing that held the screws which hold the two halves of the body of the drill.

From one body halves have to delete all unnecessary (circled in yellow).

Start upgrading the other half, where there are no grounds for fixing the incoming power.

Selected, as planned, on the sides of connector housing small depressions.

Try on. The screws should go.

Carefully cut out all unnecessary. Adapting to the millimeter. It seems ready.

Everything. Excess selected. The hole for the connector made slightly smaller diameter, so that the two halves of the hull drill clamped connector.

Cropped regular wires and crimp terminals. First wanted to solder, but then changed his mind. The garage is a lot different from the terminals remain installations.

Greasy, not wishing greased special terminals with dielectric grease. It protects the contacts from corrosion, acts against sparking.

Sobral. The first is ready!

More.

Very unusual to see a drill without exiting the handle strap.

Examples of cable "mother". It looks amazing.

Long dug in search of suitable shurupchikov to lock himself connector and screw the cap to him. Found only one. Not very suitable in length. Later remade node.

Next was the LBM (aka "Bulgarian"). REMOVE COVER-handle.

Something will have to prune. However, only one piece. On the back side of the lever start / stop button LBM.

Don hood without cable and without cable entry. Look what you can, and to what extent it is possible to saw off. Ugum-with, of course!

Try on the connector. The hole in the casing is large enough around 22 mm and the need 23-23.5 mm (connector housing has an easy taper).

Took a cone drill and a few seconds of pure Drill up to 22 mm. Continue with the Dremel cutter.

Again gauged. As seen in the following photo, the connector is still long, and then saw off can not (remember the arm start / stop). So saw off part of the connector.

Said - done.

Cooking native provodochki. Crimped terminals (on the other hand remained factory rings).

All connect to the first connector, which I managed to fasten to the housing with two screws M3.

Next to the button.

Collect. Done! Again unusual thing bezshnurovogo tool.

More

The third patient - Circular handsaw. Input power cable in it is made is not very comfortable - the side. Why not make a butt handles - known only to the Chinese. Would like to place in another way, but lacks the thickness of the handle. We'll have to do as it was in stock. Try on the connector. He, too, will have to be shortened.

Parse saw. See inside. Yeah, the cable entry hole diameter bigger inside than outside. Already well.

Bite off excess stock and remove the cable entry. Excellent.

A few seconds of a conical drill hole of required diameter and expanded. In the saw, I decided to ream the hole to 24 mm, as had yet to dig in and find the right mess shurupchiki. Found a lot of good young shurupchikov. Here, everything is ready.

See how much exactly sawing off of the connector. But first, you need to remove one edge of the mesh stiffness in the handle of the saw. That's better!

All anchoring, connect.

And collect the saw back as it was. Krasoten!

Took a piece of cable boxes PVA 2x2, 5 square. There's also found a loose plug. Kabelёk rigged. Well, actually, here it is - one for all and all for one.

End of confusing cables. Worked tool unplugged, took another - connected. In addition to the facilities in operation, increasing convenience store tool - no need to do wiring compartment.

How could notice the most observant, I made three tools, and the panel took four nests. The latter would love to be integrated in the new Bosch jigsaw, but I fear that it would deprive him of the warranty. In the old Phiolent not want to spend jack. While pondering. A bit later, so I will alter the rest of the instrument. Just use these more often.

Actually everything.

38 photo.

Picture looked like this:

Last night, once again surf the Internet in search of interesting solutions for the storage of certain instruments and consumables for them, stumbled on this picture (then found the article author). Interesting idea, I thought. And instantly I have matured a similar idea. The decision on the picture is good, but the connectors are not fixed. In the process, anything can happen (I often step on the wire, for example). You had a decision to commit.

Wool began internet for various connectors and 5 minutes later came a second insight - Speakon! Spikony used in the professional concert environment, they connect the speakers to the amplifier. Meet - PowerCon!

Things are expensive, but they are his. Checked experience. I was not sure whether I can mount sockets inside the case of all instruments. In extreme cases, if not obtained, decided that I will do like the picture, which has found. So, the first patient, whom I decided to dissect - drill. Disassemble, see the following picture.

Try on the connector. Hmm, if slightly modify it, you can shove. We'll have two sides with little to choose plastic casing that held the screws which hold the two halves of the body of the drill.

From one body halves have to delete all unnecessary (circled in yellow).

Start upgrading the other half, where there are no grounds for fixing the incoming power.

Selected, as planned, on the sides of connector housing small depressions.

Try on. The screws should go.

Carefully cut out all unnecessary. Adapting to the millimeter. It seems ready.

Everything. Excess selected. The hole for the connector made slightly smaller diameter, so that the two halves of the hull drill clamped connector.

Cropped regular wires and crimp terminals. First wanted to solder, but then changed his mind. The garage is a lot different from the terminals remain installations.

Greasy, not wishing greased special terminals with dielectric grease. It protects the contacts from corrosion, acts against sparking.

Sobral. The first is ready!

More.

Very unusual to see a drill without exiting the handle strap.

Examples of cable "mother". It looks amazing.

Long dug in search of suitable shurupchikov to lock himself connector and screw the cap to him. Found only one. Not very suitable in length. Later remade node.

Next was the LBM (aka "Bulgarian"). REMOVE COVER-handle.

Something will have to prune. However, only one piece. On the back side of the lever start / stop button LBM.

Don hood without cable and without cable entry. Look what you can, and to what extent it is possible to saw off. Ugum-with, of course!

Try on the connector. The hole in the casing is large enough around 22 mm and the need 23-23.5 mm (connector housing has an easy taper).

Took a cone drill and a few seconds of pure Drill up to 22 mm. Continue with the Dremel cutter.

Again gauged. As seen in the following photo, the connector is still long, and then saw off can not (remember the arm start / stop). So saw off part of the connector.

Said - done.

Cooking native provodochki. Crimped terminals (on the other hand remained factory rings).

All connect to the first connector, which I managed to fasten to the housing with two screws M3.

Next to the button.

Collect. Done! Again unusual thing bezshnurovogo tool.

More

The third patient - Circular handsaw. Input power cable in it is made is not very comfortable - the side. Why not make a butt handles - known only to the Chinese. Would like to place in another way, but lacks the thickness of the handle. We'll have to do as it was in stock. Try on the connector. He, too, will have to be shortened.

Parse saw. See inside. Yeah, the cable entry hole diameter bigger inside than outside. Already well.

Bite off excess stock and remove the cable entry. Excellent.

A few seconds of a conical drill hole of required diameter and expanded. In the saw, I decided to ream the hole to 24 mm, as had yet to dig in and find the right mess shurupchiki. Found a lot of good young shurupchikov. Here, everything is ready.

See how much exactly sawing off of the connector. But first, you need to remove one edge of the mesh stiffness in the handle of the saw. That's better!

All anchoring, connect.

And collect the saw back as it was. Krasoten!

Took a piece of cable boxes PVA 2x2, 5 square. There's also found a loose plug. Kabelёk rigged. Well, actually, here it is - one for all and all for one.

End of confusing cables. Worked tool unplugged, took another - connected. In addition to the facilities in operation, increasing convenience store tool - no need to do wiring compartment.

How could notice the most observant, I made three tools, and the panel took four nests. The latter would love to be integrated in the new Bosch jigsaw, but I fear that it would deprive him of the warranty. In the old Phiolent not want to spend jack. While pondering. A bit later, so I will alter the rest of the instrument. Just use these more often.

Actually everything.