1449

Artificial Stone

I want to share what I was doing 1.5 years, and Precisely manufacture products made of artificial stone.

15 photos and 1 video

It so happened that I, along with my friends decided to open a busi- produce countertops, windowsills, tables, and other articles of artificial stone. Who knows called artificial stone mixture of the polymer component (polymer resin) and the inorganic filler with optional components (granules, dyes, etc.).

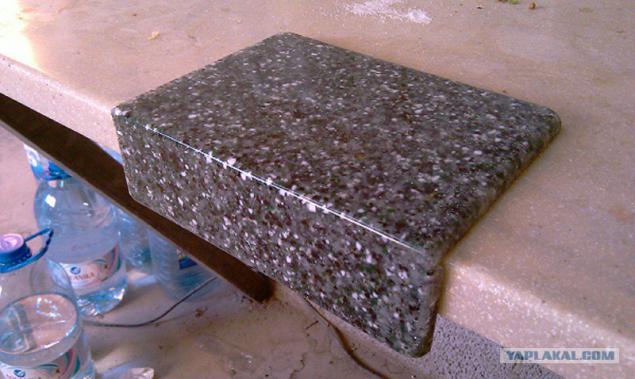

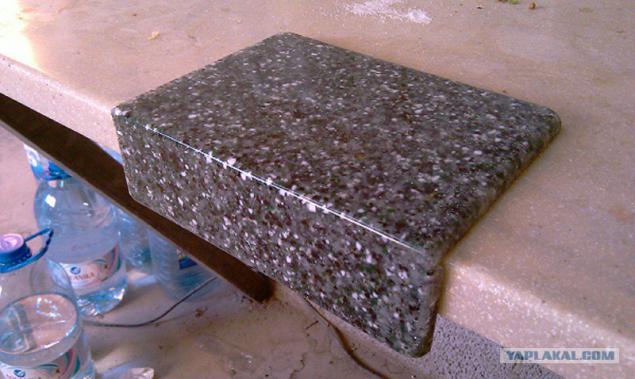

Next, the stone products are divided into 2 types: leaf and stone filler (liquid) rock. The principal difference is that the sheet comes to the production of large sheets, and then just cut the size of the customer and glued with special glue, then the stronger / supplemented substrate, mainly plywood for strength. This is somewhat similar to the production of furniture from chipboard. The photo specimen with double sheets, pen test, and a pair of end products

finished product with sink

The finished product with a sink (our production)

Stone filler characterized in that first on a form (matrix) is sprayed with a binder excipient (gelkut- gel coating, the outer coating), and then the remaining portion of the mold is filled with a mixture of the resin and the mineral component. Sometimes the inside of this "sandwich" is added wooden tab (in order to facilitate the design, material savings and reduction in price).

So, initially the production looked like this: on a sheet of glass 2m * 3m were laid shape future countertops for kitchen (face down). Then knead the required color (filler) with gelcoat, and a mixture of several layers was deposited.

sprayed with gelcoat filler

finished product (not yet captured from the table :)

Next tab is prepared from chipboard, preparing a mixture of resin with a filler, it all poured tab "establish" a place on the next day was going "autopsy". The whole operation usually takes 1 day (8-10 hours).

Occasionally receive a "garden».

Posted in [mergetime] 1404325776 [/ mergetime]

After the "opening" is processed products from coarse sandpaper to 80y 2000y, with subsequent polishing of special polishing paste. It takes 1-2 days if everything was ok with the product, and a week or more, if it detects a marriage. The main problem is the plain ware (black and white, mostly). One white stoleshku remade five (5) times.

The following process (carefully! Vertical video !!!) and the results

www.yapfiles.ru/show/893104/eb22ebf...ef075a.flv.html

behold a white stoleshka client

she's from a different perspective

shell close-up (made from scratch themselves, monolith, not glued)

it's a different order, which namumukalis vusmert. But it was worth it

Then we realized that most of the working time spent on the removal of the marriage, and began the transition to the sheet rock. But the leaves began to make themselves, knowing all the secrets.

What bliss it was when we realized that in this method there is no rounding (in the inlet stone is very often that eliminating the marriage, the surface layer of ground off, and eliminate this flaw has not been possible. Have perezalivat again), no additional operation with loss of time (sputtering), there is a tab (sheet filled 8-10mm, which is then cut into the desired size and glued on the outside glued plywood). In general marriage practically impossible. Besides, you can make awesome products like marble (artificial marble).

here's a sample of marble.

In addition, there was a lot of projects / problems involved in the production and sinks (sinks) over matrices, and body kit for cars, and other interesting things.

another product of the matrix

and another

Then we realized that most of the working time spent on the removal of the marriage, and began the transition to the sheet rock. But the leaves began to make themselves, knowing all the secrets.

What bliss it was when we realized that in this method there is no rounding (in the inlet stone is very often that eliminating the marriage, the surface layer of ground off, and eliminate this flaw has not been possible. Have perezalivat again), no additional operation with loss of time (sputtering), there is a tab (sheet filled 8-10mm, which is then cut into the desired size and glued on the outside glued plywood). In general marriage practically impossible. Besides, you can make awesome products like marble (artificial marble).

Further photos of finished products that I myself liked.

more photos

15 photos and 1 video

It so happened that I, along with my friends decided to open a busi- produce countertops, windowsills, tables, and other articles of artificial stone. Who knows called artificial stone mixture of the polymer component (polymer resin) and the inorganic filler with optional components (granules, dyes, etc.).

Next, the stone products are divided into 2 types: leaf and stone filler (liquid) rock. The principal difference is that the sheet comes to the production of large sheets, and then just cut the size of the customer and glued with special glue, then the stronger / supplemented substrate, mainly plywood for strength. This is somewhat similar to the production of furniture from chipboard. The photo specimen with double sheets, pen test, and a pair of end products

finished product with sink

The finished product with a sink (our production)

Stone filler characterized in that first on a form (matrix) is sprayed with a binder excipient (gelkut- gel coating, the outer coating), and then the remaining portion of the mold is filled with a mixture of the resin and the mineral component. Sometimes the inside of this "sandwich" is added wooden tab (in order to facilitate the design, material savings and reduction in price).

So, initially the production looked like this: on a sheet of glass 2m * 3m were laid shape future countertops for kitchen (face down). Then knead the required color (filler) with gelcoat, and a mixture of several layers was deposited.

sprayed with gelcoat filler

finished product (not yet captured from the table :)

Next tab is prepared from chipboard, preparing a mixture of resin with a filler, it all poured tab "establish" a place on the next day was going "autopsy". The whole operation usually takes 1 day (8-10 hours).

Occasionally receive a "garden».

Posted in [mergetime] 1404325776 [/ mergetime]

After the "opening" is processed products from coarse sandpaper to 80y 2000y, with subsequent polishing of special polishing paste. It takes 1-2 days if everything was ok with the product, and a week or more, if it detects a marriage. The main problem is the plain ware (black and white, mostly). One white stoleshku remade five (5) times.

The following process (carefully! Vertical video !!!) and the results

www.yapfiles.ru/show/893104/eb22ebf...ef075a.flv.html

behold a white stoleshka client

she's from a different perspective

shell close-up (made from scratch themselves, monolith, not glued)

it's a different order, which namumukalis vusmert. But it was worth it

Then we realized that most of the working time spent on the removal of the marriage, and began the transition to the sheet rock. But the leaves began to make themselves, knowing all the secrets.

What bliss it was when we realized that in this method there is no rounding (in the inlet stone is very often that eliminating the marriage, the surface layer of ground off, and eliminate this flaw has not been possible. Have perezalivat again), no additional operation with loss of time (sputtering), there is a tab (sheet filled 8-10mm, which is then cut into the desired size and glued on the outside glued plywood). In general marriage practically impossible. Besides, you can make awesome products like marble (artificial marble).

here's a sample of marble.

In addition, there was a lot of projects / problems involved in the production and sinks (sinks) over matrices, and body kit for cars, and other interesting things.

another product of the matrix

and another

Then we realized that most of the working time spent on the removal of the marriage, and began the transition to the sheet rock. But the leaves began to make themselves, knowing all the secrets.

What bliss it was when we realized that in this method there is no rounding (in the inlet stone is very often that eliminating the marriage, the surface layer of ground off, and eliminate this flaw has not been possible. Have perezalivat again), no additional operation with loss of time (sputtering), there is a tab (sheet filled 8-10mm, which is then cut into the desired size and glued on the outside glued plywood). In general marriage practically impossible. Besides, you can make awesome products like marble (artificial marble).

Further photos of finished products that I myself liked.

more photos