850

It made us

1. About the "Swallows" is not just lazy writing, but to see them live ever not all. As long as they are physically not much compared to the tens of thousands of cars more traditional models of trains. The country is a big one. Correct deficit "red birds" Railways have decided to plant "Ural Locomotives" that near Yekaterinburg. I was invited in Verkhnyaya Pyshma look at the very first domestic "Swallow" and look at its production.

2. "Original" simensovskie train, the same ones that were used as urban trains in Sochi, in the Russian localization remain the same from the outside, but the inside will be different.

3. The main and fundamental difference from the trains serving Sochi - Ural "Swallows" are designed for high passenger traffic and are designed for use in large metropolitan areas on highways with a constant current. That is not to express Moscow - Nizhny and urban or suburban train.

4.

5.

6. The spacious interior looks more like a contemporary interior of the bus. Developers have gone from ideas facing seats opposite each other, and now they are deployed in the same direction. Specifically, the interior was designed specifically for small ring of the Moscow railway. Therefore, so many seats.

7. The cars have spacious restrooms adapted for wheelchair users.

8. wide area in front of the doors, which can stand strollers, bicycles and passengers with bulky luggage.

9. Along the windows are hangers for clothes. In Sochi versions for luggage shelves were located outlet 220, here they are transferred to the floor level. One of the outlets can be seen in the previous photo.

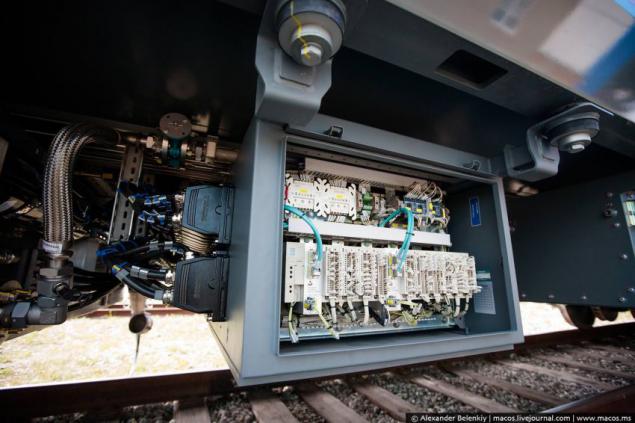

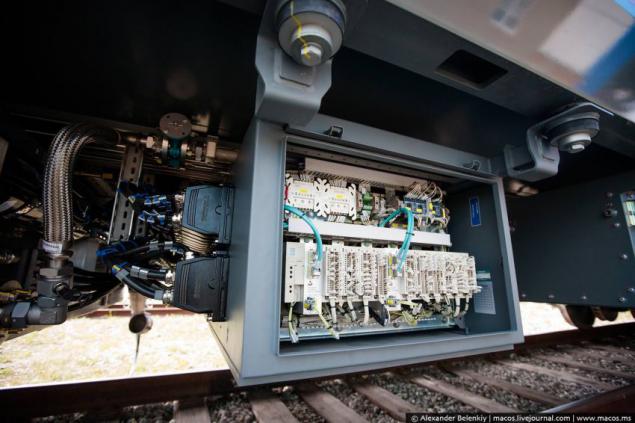

10. Locomotive at least speed (the maximum speed - 160 km / h), but much greater than previously manufactured European models of power, safety and reliability parameters to use. Ural "Swallow" - a more powerful machine, capable with frequent stops to pick up speed quickly.

11. Due to the difficult Russian topographical conditions brought increased demands on the system avtotormoznogo and haulage equipment.

12. In the middle of the axis of the previous pictures - brake drums. Close up they look even more impressive.

13. Let the officials and the press to inspect the train.

14. And to hear a long list of innovations and changes.

15. Behind employees try to get lost in the vast halls.

16. Getting lost is where. Workshops huge but bright and clean.

17. Here and there a handful of teams of workers.

18. Components for future trains.

19. In this shop going to "swallow". Now assemble the train №2 and №3.

20. When assembling the first of these trains in Russian technology was used used as the main structural material body precision hollow extruded aluminum profiles, treated at high hardness. Whatever that meant. The photo is just a process of cutting out the side of the car.

21. After the assembly is obtained here is a hollow aluminum body.

22. Next is the painting in a special chamber, inset windows, installation of doors and door components.

23. Installation of internal wiring and equipment, installation of thermal insulation, sound insulation and decorative panels.

24. Mounting of attachments, the output communication and preparation for the installation of wheel pairs.

25. Then the car is raised with special jacks and mounted on wheels.

26. The final part is connected all of the equipment is checked at the stand and the car is ready for acceptance.

27. In 2014, the plant plans to release the first nine pyativagonnyh trains and spend their certification. In 2015, the railroad will put 30 more trains. And just before 2020 on the "Ural locomotives" commissioned by Russian Railways will be made in 1200 cars. How much does it "swallows" - count yourself :)

28. Do you have riding on this train?

Source: macos.livejournal.com

2. "Original" simensovskie train, the same ones that were used as urban trains in Sochi, in the Russian localization remain the same from the outside, but the inside will be different.

3. The main and fundamental difference from the trains serving Sochi - Ural "Swallows" are designed for high passenger traffic and are designed for use in large metropolitan areas on highways with a constant current. That is not to express Moscow - Nizhny and urban or suburban train.

4.

5.

6. The spacious interior looks more like a contemporary interior of the bus. Developers have gone from ideas facing seats opposite each other, and now they are deployed in the same direction. Specifically, the interior was designed specifically for small ring of the Moscow railway. Therefore, so many seats.

7. The cars have spacious restrooms adapted for wheelchair users.

8. wide area in front of the doors, which can stand strollers, bicycles and passengers with bulky luggage.

9. Along the windows are hangers for clothes. In Sochi versions for luggage shelves were located outlet 220, here they are transferred to the floor level. One of the outlets can be seen in the previous photo.

10. Locomotive at least speed (the maximum speed - 160 km / h), but much greater than previously manufactured European models of power, safety and reliability parameters to use. Ural "Swallow" - a more powerful machine, capable with frequent stops to pick up speed quickly.

11. Due to the difficult Russian topographical conditions brought increased demands on the system avtotormoznogo and haulage equipment.

12. In the middle of the axis of the previous pictures - brake drums. Close up they look even more impressive.

13. Let the officials and the press to inspect the train.

14. And to hear a long list of innovations and changes.

15. Behind employees try to get lost in the vast halls.

16. Getting lost is where. Workshops huge but bright and clean.

17. Here and there a handful of teams of workers.

18. Components for future trains.

19. In this shop going to "swallow". Now assemble the train №2 and №3.

20. When assembling the first of these trains in Russian technology was used used as the main structural material body precision hollow extruded aluminum profiles, treated at high hardness. Whatever that meant. The photo is just a process of cutting out the side of the car.

21. After the assembly is obtained here is a hollow aluminum body.

22. Next is the painting in a special chamber, inset windows, installation of doors and door components.

23. Installation of internal wiring and equipment, installation of thermal insulation, sound insulation and decorative panels.

24. Mounting of attachments, the output communication and preparation for the installation of wheel pairs.

25. Then the car is raised with special jacks and mounted on wheels.

26. The final part is connected all of the equipment is checked at the stand and the car is ready for acceptance.

27. In 2014, the plant plans to release the first nine pyativagonnyh trains and spend their certification. In 2015, the railroad will put 30 more trains. And just before 2020 on the "Ural locomotives" commissioned by Russian Railways will be made in 1200 cars. How much does it "swallows" - count yourself :)

28. Do you have riding on this train?

Source: macos.livejournal.com