631

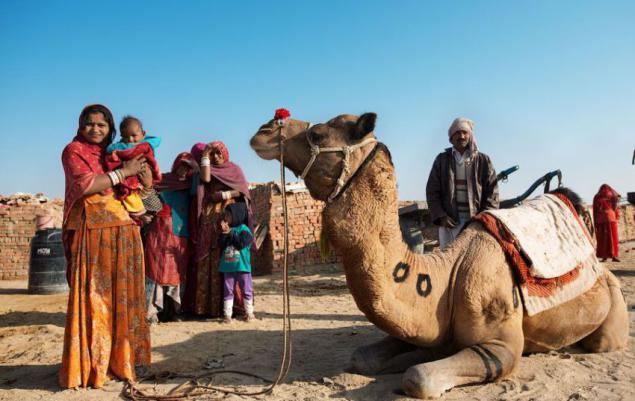

Brick production in India

Women as well as in many Asian countries engaged in hard work. First, the sand fraction must be brought to the workers who mix it with water.

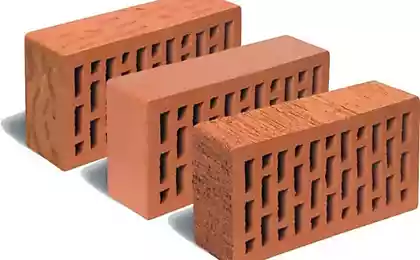

Clay with water forms a mass which retains its shape after drying and after firing acquires the properties of the stone. Plasticity is due to the penetration of water, good natural solvent between the individual particles of clay minerals.

Ugly Bulbash put in a molding with a distinctive sign of the manufacturer.

The process at first glance seems very interesting. Especially under the Indian music. Oh and XXI century civilization resembles a receiver connected to the solar panels. Oh, something which, as the sun and wind in the Thar Desert rife. After the forming process, the bricks should be dry before the final firing process.

By driving up the brick kilns on camels.

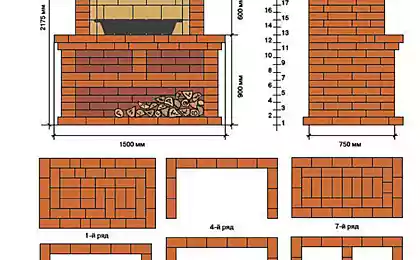

The furnace melt manure. Bricks poured ash and sand for a few days. After that, to deal with the oven cooled hand and pull already deified finished bricks.

For here is a bulk furnace working day and night workers.

After firing, the bricks are taken and placed in piles for further transportation.

Meanwhile, us running around begging rebyatnya rupee and candy.

Here in the heart of the desert, away from all the benefits of civilization as well as a few centuries ago can be seen the measured life of artisans and their families. In India, almost anywhere, whether it's building or manufacturing people live close to work. And it seems to me that people are much happier and we have to adapt. After all, what happen, they will not need any internet connection, no TV, no ribbon tweeter. Or maybe I'm wrong? Perhaps the work will fall if the tunes of Bollywood Indian singer cease to sound in the heart of a small, but very proud of the Indian plant for the production of red as the sun setting every day of the dunes of the Thar Desert bricks.

Source: vtaysaev.livejournal.com