1454

Construction Bugrinsky Bridge in Novosibirsk

Bugrinsky Bridge - the third road bridge being built in Novosibirsk over the Ob River. April 11, 2014 the final stage of sliding roof arch: two flights from different shores closed at the height of over 90 meters. Let's see how it was. The construction of buildings is atypical: the transition channel keeps semicircular arch. Over 120 years of Novosibirsk is built not so much objects that formed a recognizable silhouette of the city. Bugrinsky Bridge - certainly one of them.

The bridge is an important part of a promising highway "Southwest bypass."

Highway 20 km long will connect the federal highway M-51 and M-52.

The total length of the bridge with a view of interchanges will be 5480 meters.

The main structural element of the bridge - span across the Ob river bed, which is flexible rigging metal arch supports.

The length of the arch - 380 meters, height - 70!

It is the largest arch span in Russia and the CIS.

It is necessary to cover the geological fault running along the bottom of the Ob River and into the zone of construction of the bridge.

Construction works are the general contractor of "Sibmost».

Six lanes (three in each direction), the new bridge must provide a minimum capacity of 4,800 vehicles per hour.

Just riverbed was constructed 6 temporary supports.

The highest temporary supports №5 and №6.

15 meters height shipping span of 70 meters and height of the arch.

During the construction of the bridge used metal factories of Kurgan and Ulan-Ude.

Slipway for assembly and sliding polusvodov arch (on the support №6 - berth №2, on a support №5 - berth №1)

Method vertical sliding arches arch contour at an angle of 45 degrees used in the construction of bridge Bugrinskogo applied for the first time in the world.

Device for sliding (hydraulic jacks)

For once the jack can move the beam two meters.

The rate at which multi-ton jacks push the tightening of the arch of the bridge is about 10 cm per minute.

In order to reduce the friction of the arch of the temporal support used prefabricated plywood skids ("carriage"), which enclose as sliding on the slip sheet.

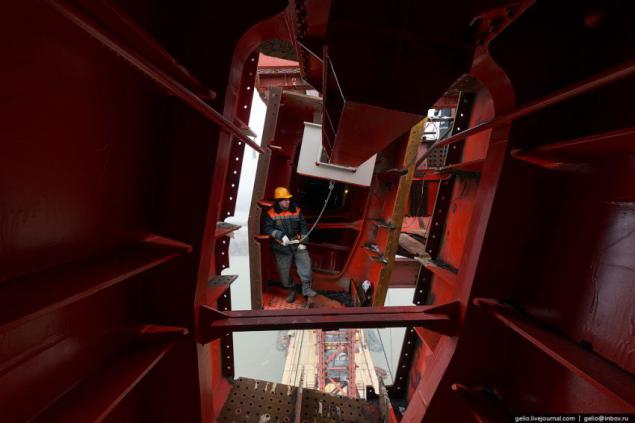

Builders, placed on the anvil should be to these "carriage" had been replaced with new ones in time.

To arch under its own weight is not left long ago, there are three "rod" - dividagi.

They work like insurance - after / before mounting them hanging all polusvod.

One side they are fixed for the slipway and the other from the bottom to the beam (there is a special focus),

while sliding installers tighten the nut, thus picking up the slack.

After sliding on arches blocks are unnecessary elements, such as loops or transport Chock "dividagi".

They are cut, and place cut stripped.

A device for removing avanbeka.

Avanbek - auxiliary guide the design of the console, join the front of the impending the span during the construction of the bridge.

For precise positioning polusvodov arches while sliding used three geodetic GPS device.

Two at the ends of the first blocks, and one at the middle of the bridge.

Sliding arches lasted 129 days.

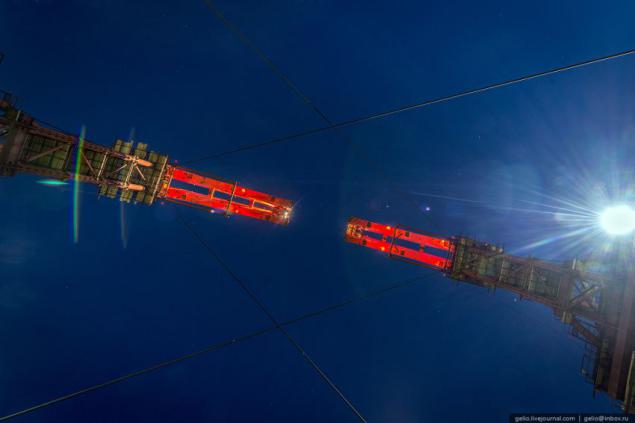

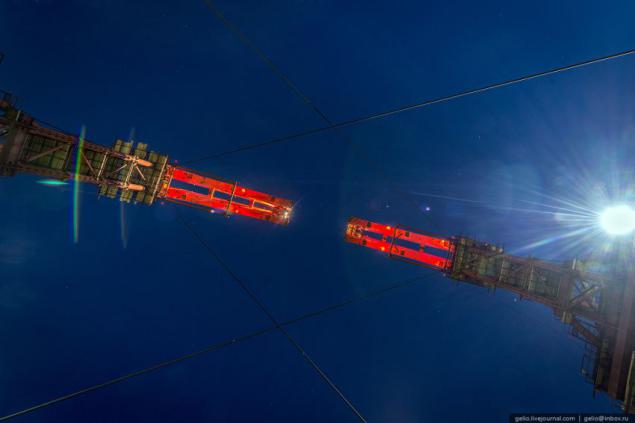

Rainy night before the final stage.

April 11, 2014.

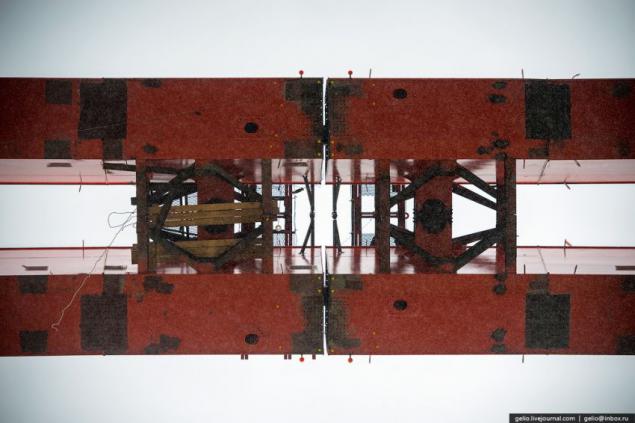

You're 1 meter 10 cm!

The installer performs a visual inspection of precision docking.

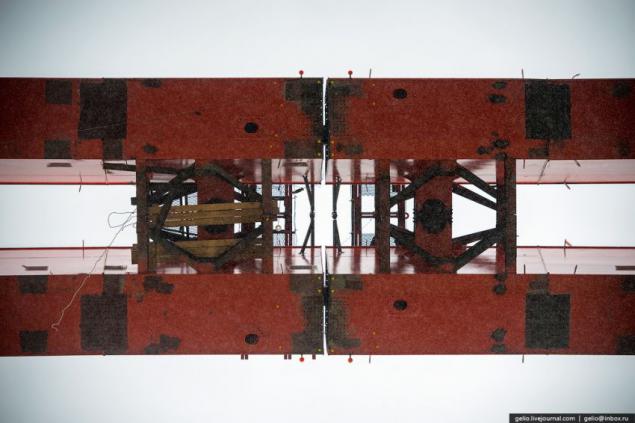

Coarse positioning device polusvodov arch-type "Papa-Mama»

The blocks are mounted on a set of high-strength bolts with a diameter of 22mm and a length of 65mm to 120mm.

At the junction of the two units need 563 bolt.

The historical moment - the completion of joining arch arches.

The photo clearly visible oval hole in the guy who will start.

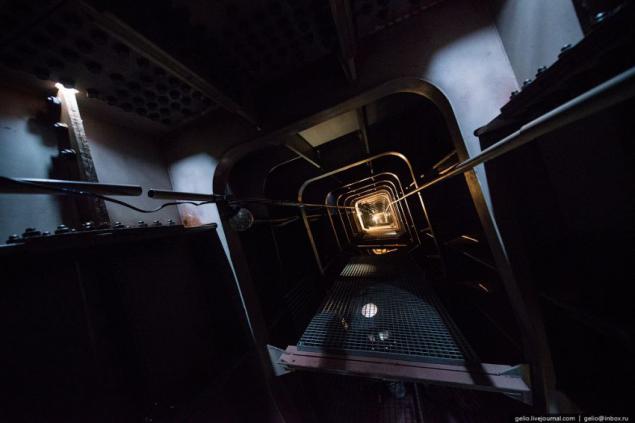

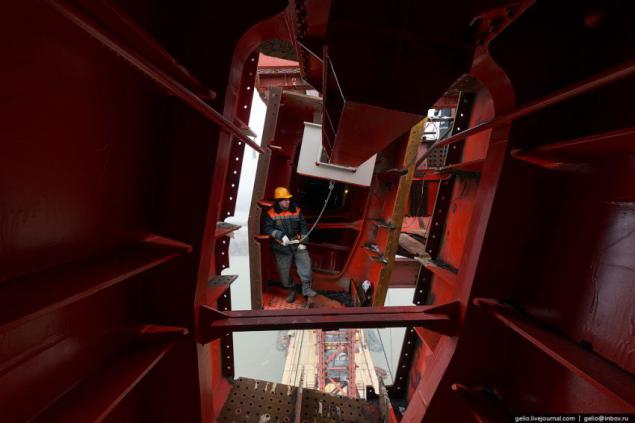

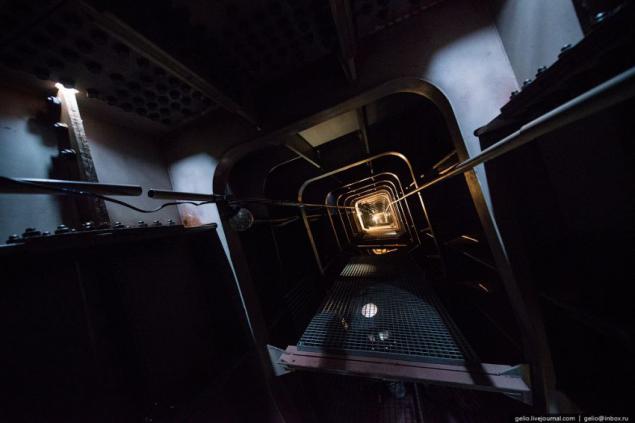

Inside the arches there are blocks passage for operational control tension guys and bolts.

Guys supporting temporary supports.

In May, builders will start the installation of the cable system. In total it is found 156 guys (most of the guys has a length of 109 meters).

All fitters and welders working on the bridge have a permit to work at height.

The usual schedule for local workers 2 shifts per day + 2 shifts into the night, followed by 4 days off. The change is from 8:00 to 20:00, and vice versa). There is another option - to watch 15 shifts per day, followed by 15 days of rest

Installers spanned friction connection.

Each bolt must be tightened by a certain force (calibration), for that they tighten torque wrench.

After tightening the representative of the customer carries out acceptance bolts.

Crawler Crane XCMG QUY150 (China) with carrying capacity of 150 tons for the mounting of the arch.

"Crossings" - their task is to give the arch rigidity.

Total number 38 Mostootryad specialists of the Novosibirsk branch of "Sibmost" was installed 88 units vault arches with a total weight 3607 tons.

Against the background of the Public Bridge

The total cost of the bridge is estimated at 14, 8 billion rubles.

Construction of the bridge began in 2010.

It is expected that the bridge will be commissioned in late September and early October 2014.

Obviously Bugrinsky Bridge will become the new symbol of the capital of Siberia.

Source: gelio.livejournal.com

The bridge is an important part of a promising highway "Southwest bypass."

Highway 20 km long will connect the federal highway M-51 and M-52.

The total length of the bridge with a view of interchanges will be 5480 meters.

The main structural element of the bridge - span across the Ob river bed, which is flexible rigging metal arch supports.

The length of the arch - 380 meters, height - 70!

It is the largest arch span in Russia and the CIS.

It is necessary to cover the geological fault running along the bottom of the Ob River and into the zone of construction of the bridge.

Construction works are the general contractor of "Sibmost».

Six lanes (three in each direction), the new bridge must provide a minimum capacity of 4,800 vehicles per hour.

Just riverbed was constructed 6 temporary supports.

The highest temporary supports №5 and №6.

15 meters height shipping span of 70 meters and height of the arch.

During the construction of the bridge used metal factories of Kurgan and Ulan-Ude.

Slipway for assembly and sliding polusvodov arch (on the support №6 - berth №2, on a support №5 - berth №1)

Method vertical sliding arches arch contour at an angle of 45 degrees used in the construction of bridge Bugrinskogo applied for the first time in the world.

Device for sliding (hydraulic jacks)

For once the jack can move the beam two meters.

The rate at which multi-ton jacks push the tightening of the arch of the bridge is about 10 cm per minute.

In order to reduce the friction of the arch of the temporal support used prefabricated plywood skids ("carriage"), which enclose as sliding on the slip sheet.

Builders, placed on the anvil should be to these "carriage" had been replaced with new ones in time.

To arch under its own weight is not left long ago, there are three "rod" - dividagi.

They work like insurance - after / before mounting them hanging all polusvod.

One side they are fixed for the slipway and the other from the bottom to the beam (there is a special focus),

while sliding installers tighten the nut, thus picking up the slack.

After sliding on arches blocks are unnecessary elements, such as loops or transport Chock "dividagi".

They are cut, and place cut stripped.

A device for removing avanbeka.

Avanbek - auxiliary guide the design of the console, join the front of the impending the span during the construction of the bridge.

For precise positioning polusvodov arches while sliding used three geodetic GPS device.

Two at the ends of the first blocks, and one at the middle of the bridge.

Sliding arches lasted 129 days.

Rainy night before the final stage.

April 11, 2014.

You're 1 meter 10 cm!

The installer performs a visual inspection of precision docking.

Coarse positioning device polusvodov arch-type "Papa-Mama»

The blocks are mounted on a set of high-strength bolts with a diameter of 22mm and a length of 65mm to 120mm.

At the junction of the two units need 563 bolt.

The historical moment - the completion of joining arch arches.

The photo clearly visible oval hole in the guy who will start.

Inside the arches there are blocks passage for operational control tension guys and bolts.

Guys supporting temporary supports.

In May, builders will start the installation of the cable system. In total it is found 156 guys (most of the guys has a length of 109 meters).

All fitters and welders working on the bridge have a permit to work at height.

The usual schedule for local workers 2 shifts per day + 2 shifts into the night, followed by 4 days off. The change is from 8:00 to 20:00, and vice versa). There is another option - to watch 15 shifts per day, followed by 15 days of rest

Installers spanned friction connection.

Each bolt must be tightened by a certain force (calibration), for that they tighten torque wrench.

After tightening the representative of the customer carries out acceptance bolts.

Crawler Crane XCMG QUY150 (China) with carrying capacity of 150 tons for the mounting of the arch.

"Crossings" - their task is to give the arch rigidity.

Total number 38 Mostootryad specialists of the Novosibirsk branch of "Sibmost" was installed 88 units vault arches with a total weight 3607 tons.

Against the background of the Public Bridge

The total cost of the bridge is estimated at 14, 8 billion rubles.

Construction of the bridge began in 2010.

It is expected that the bridge will be commissioned in late September and early October 2014.

Obviously Bugrinsky Bridge will become the new symbol of the capital of Siberia.

Source: gelio.livejournal.com