1360

Micron plant. Part 1.

Factory "Micron" was created in Zelenograd in the 60s of the last century for the development of domestic and industrial production of integrated circuits. "Micron" - the largest microelectronics company in Russia and the CIS countries in terms of sales. Next quote author.

Originally silicon looks like. He is a natural semiconductor.

First there was a silicon chip :) This is the foundation.

Silicon is melted in a silicon rod is inserted, then the mass of molten silicon cools and crystallizes around this core.

Cylinder "shred" on thin layers

Then some parts of etching acid and turns is such a blank

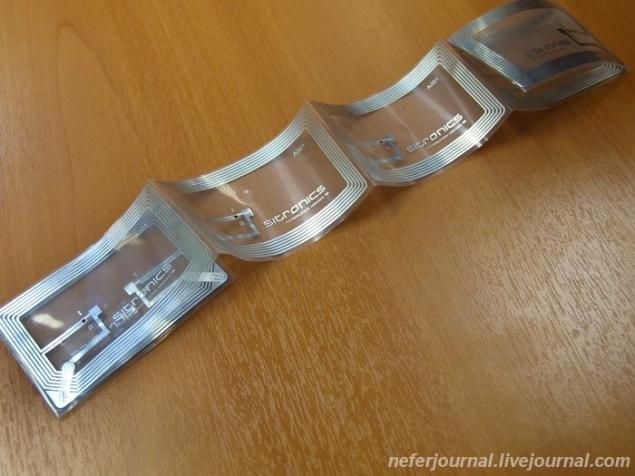

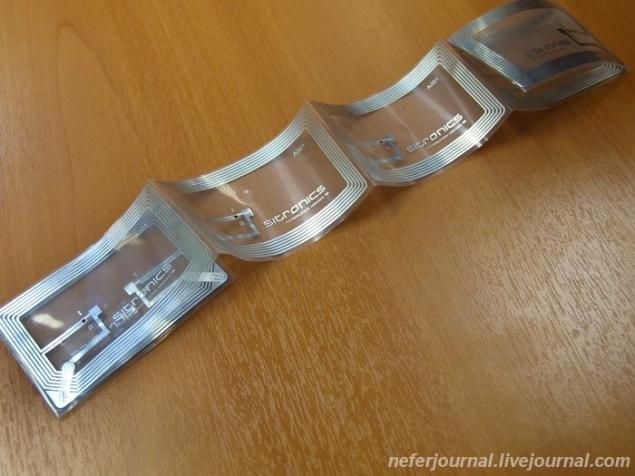

And this is a blank for metrobiletov, they're lying on the table, decided to take a picture. On the "Micron" make transportation, discount, payment, social insurance and medical records, as well as ski passes and passport chip. And all this is done is called a "turnkey", that is, inside and out, a full cycle. This permits control the quality of each stage of production and to improve the degree of security.

We go through an underpass on the production

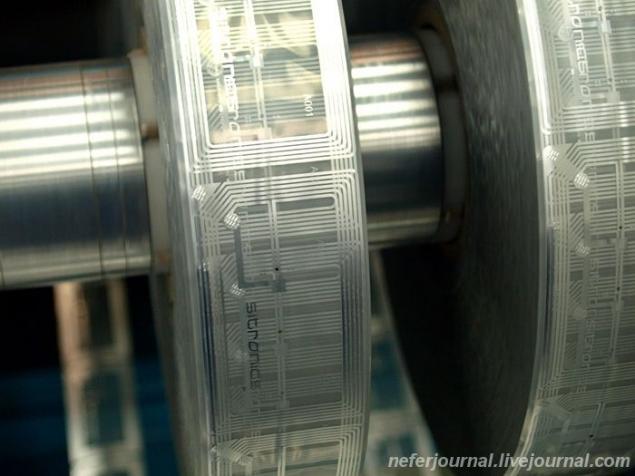

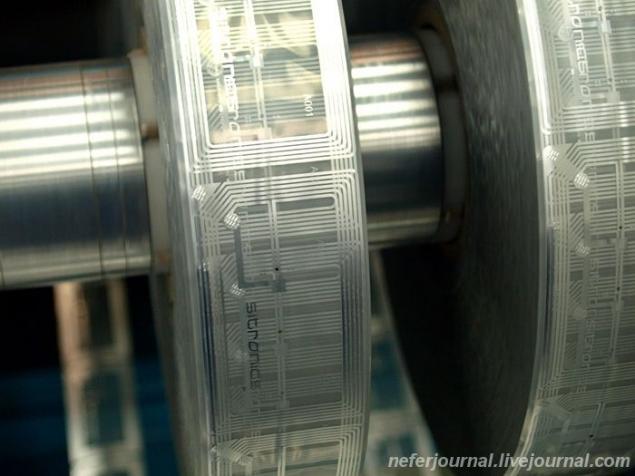

Here are the most nedobiletiki. This workshop takes place the so-called assembly inlays.

If you look closely, you will notice that this is already zagotovochke flyspeck posed robot

Here, in this booth and robot puts this flyspecked chip. Generally in the shops there is something incomprehensible, each machine is divided into these cabins, in each cabin sits robot and does its job. Then it all moves to the next booth. I looked at some, watched them and did not understand anything.

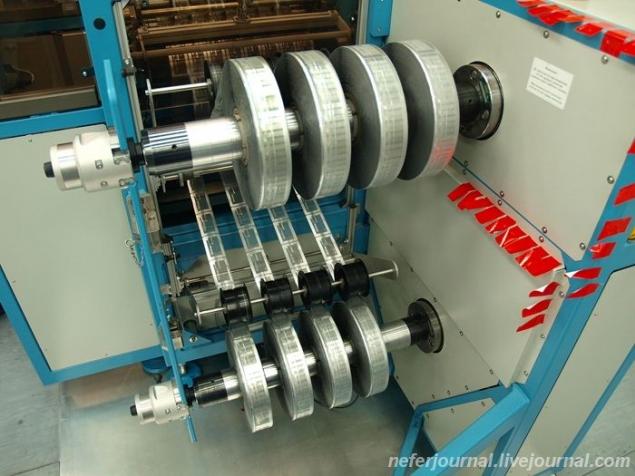

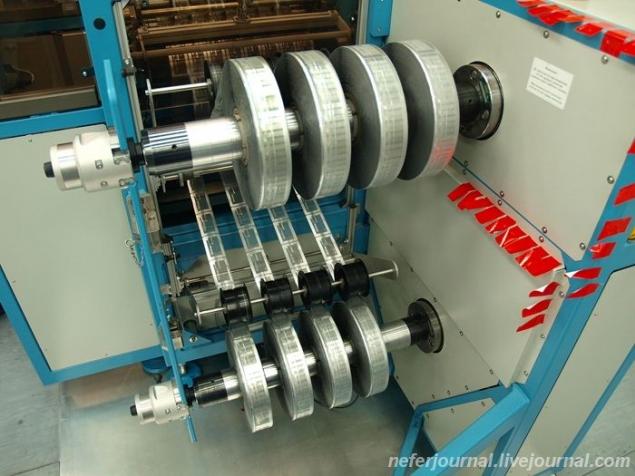

But here it is clear to me - a single ticket for November! A pair of coils tickets :)

Here are assembled tickets

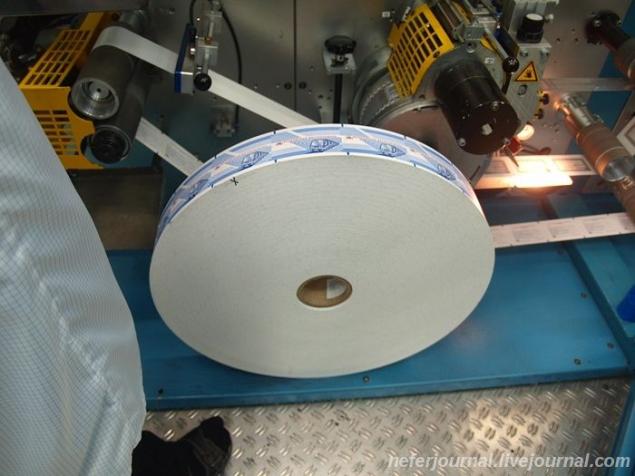

Uncle changed roll, this is ready

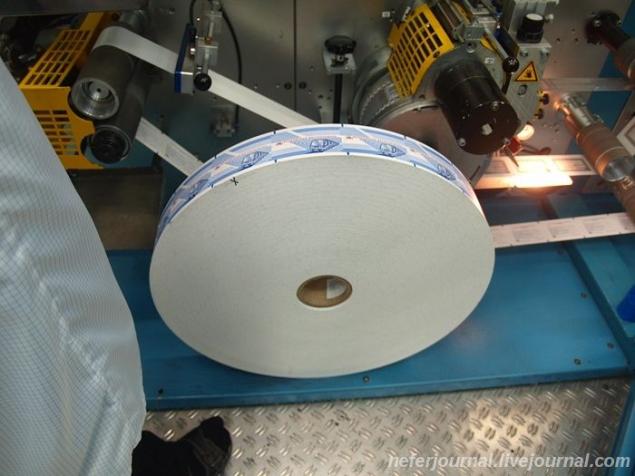

These pieces are sealed in a synthetic shell, similar to the paper, it is resistant to tearing and mechanical damage, with all the cost of the final product using this technology below the cost of plastic counterparts.

Go to the next shop

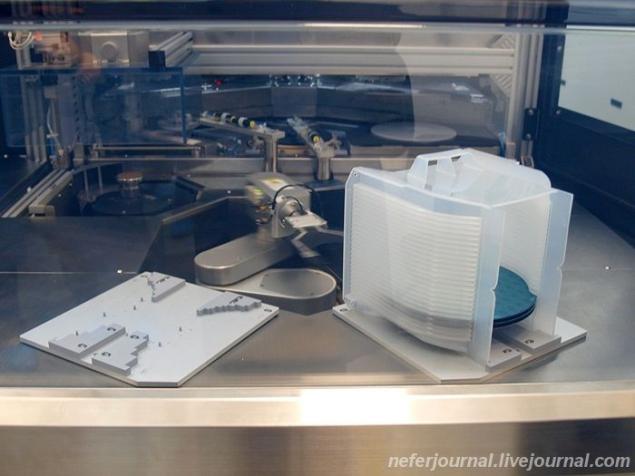

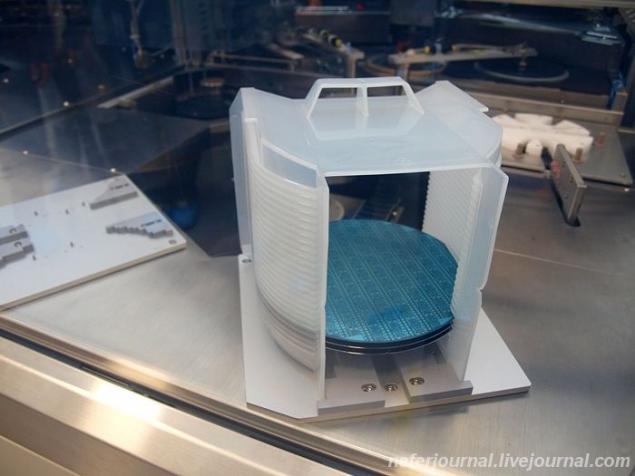

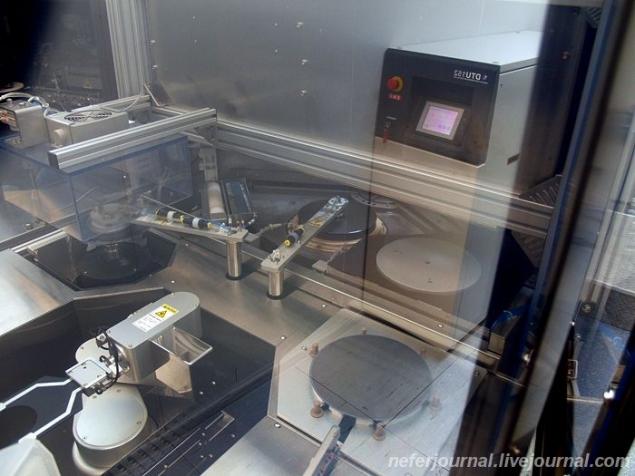

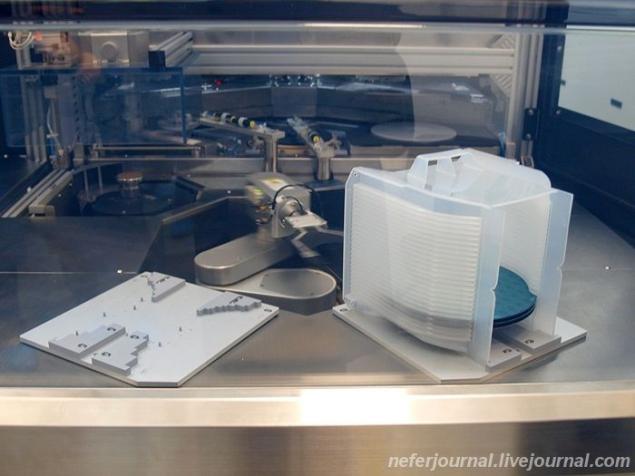

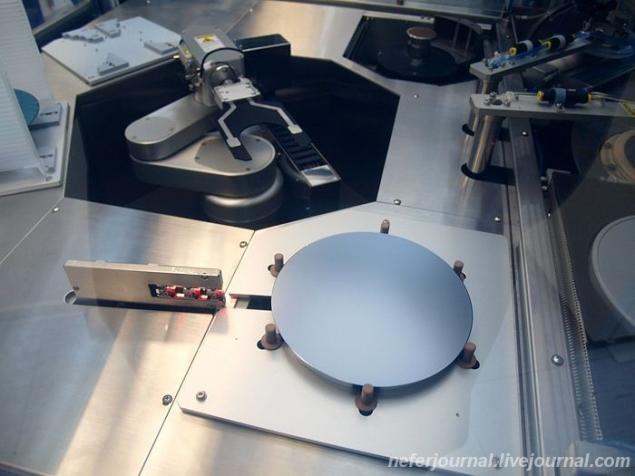

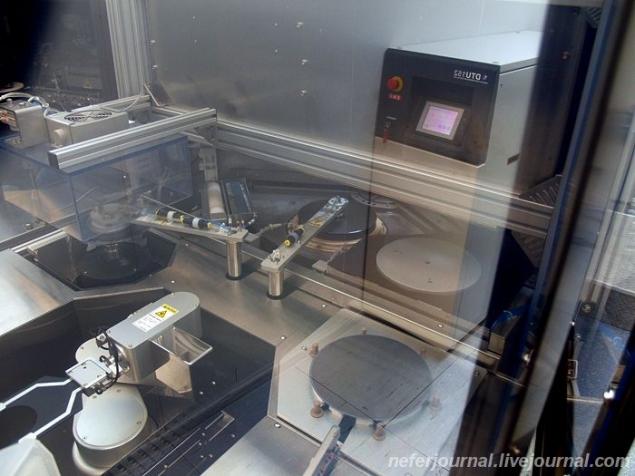

Now, from ready-tickets, we take a few steps back to that same plate, which is cut off from the silicon cylinder. Despite the fact that the plate is thin, it is necessary to make it Tonci. This process is called - thinning. This is done as robots inside the chamber, one robot picks up the plate and delivers another robot, which puts it on a special drive where necking occurs.

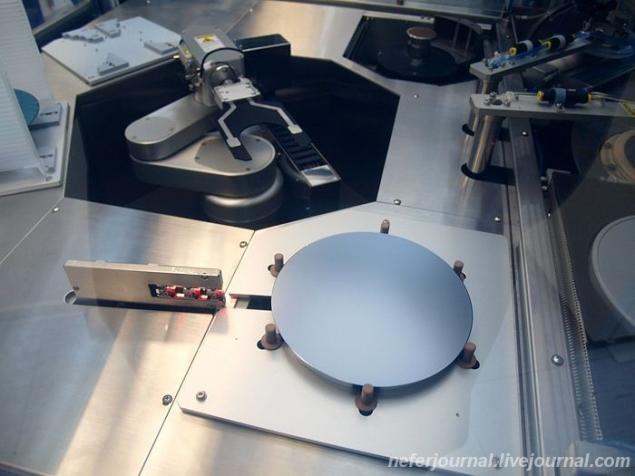

Here he put the disc to the next robot took her

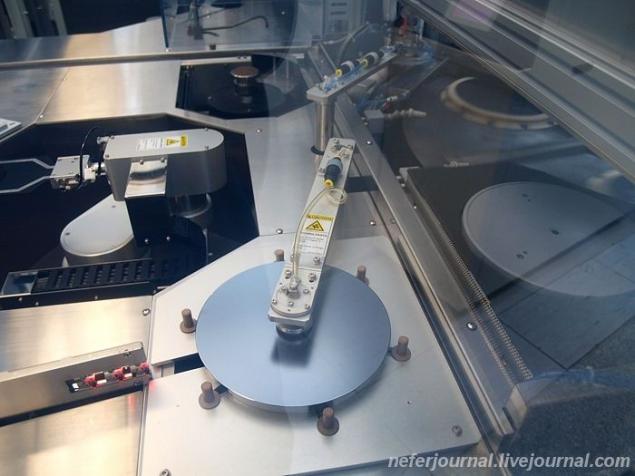

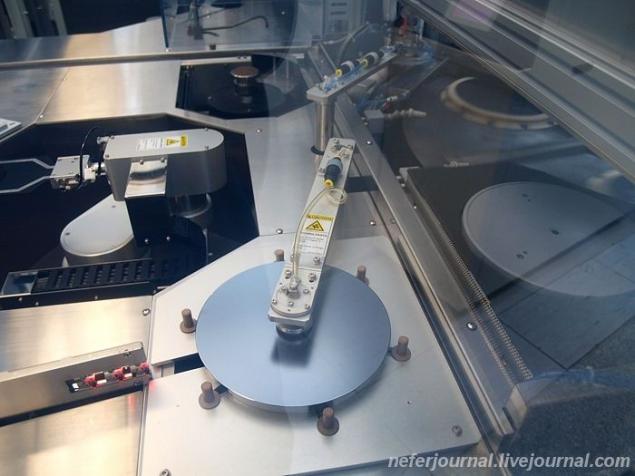

Here, the second robot just takes drive, has not been able to catch this moment

When we watched the thinning noticed that there is some kind of liquid. It reminded me of a pancake, hissing and shkvorchaschy on oil. Of course it was not oil, said it deionized water.

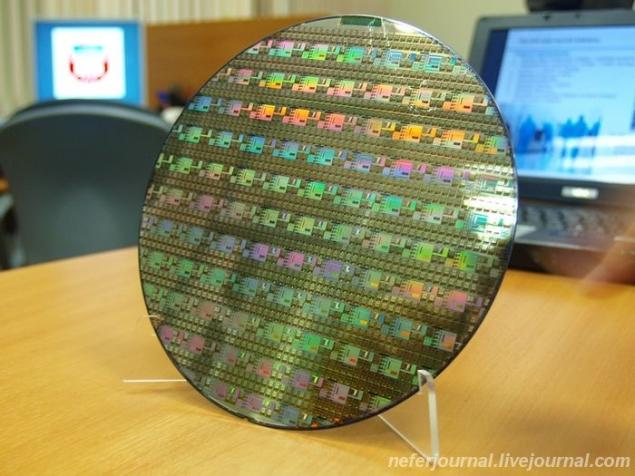

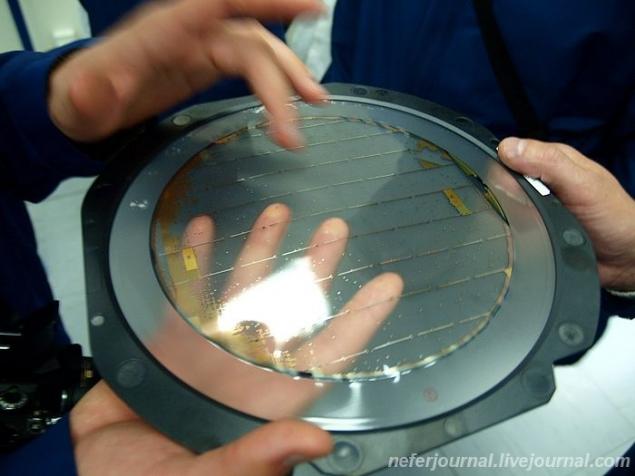

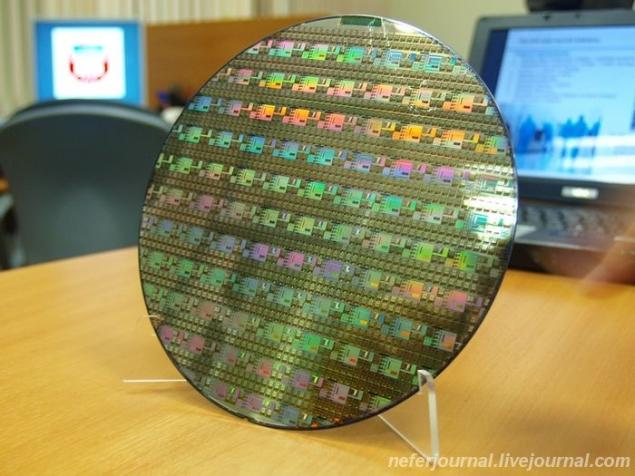

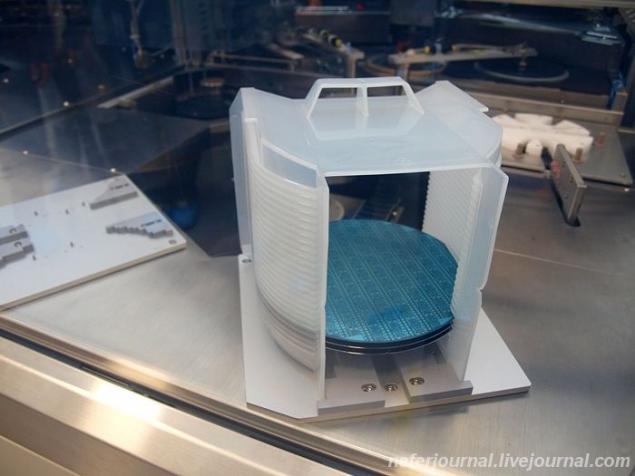

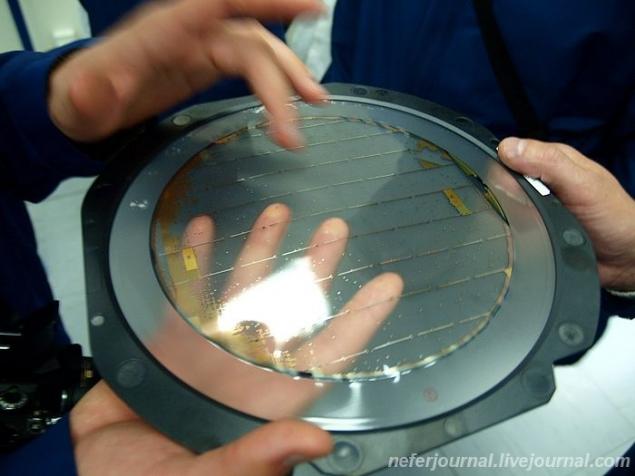

This exhaust disc. Small squares area of less than 1 square. mm - it chips. I understand this RFID-chips (Radio Frequency IDentification - RFID) used just as contactless smart cards of the Moscow metro.

Memory photo

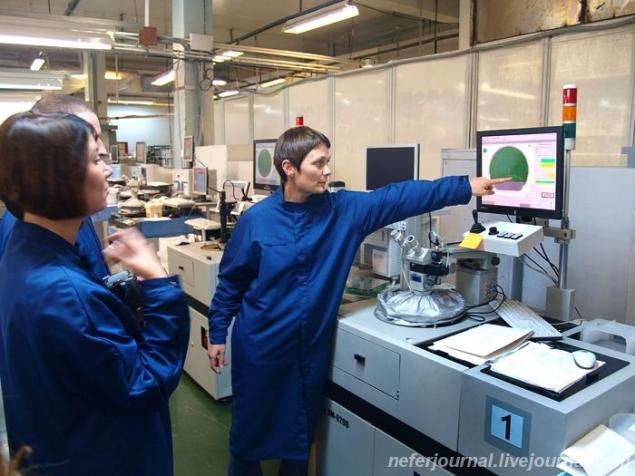

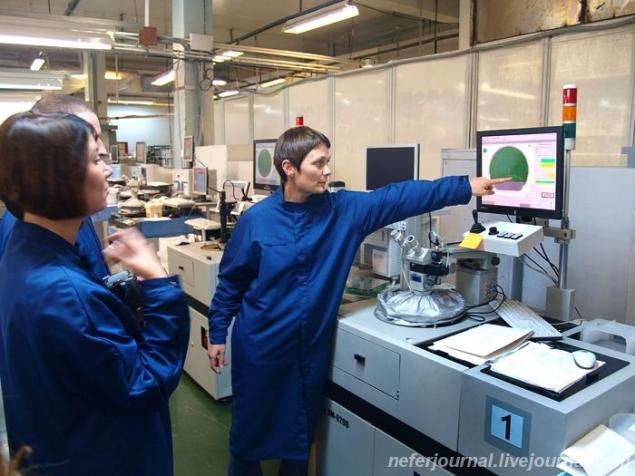

Here comes the test. Some manufacturers have already tested the final product, on the "Micron" as there is such a intermediate control, very radeyut for quality.

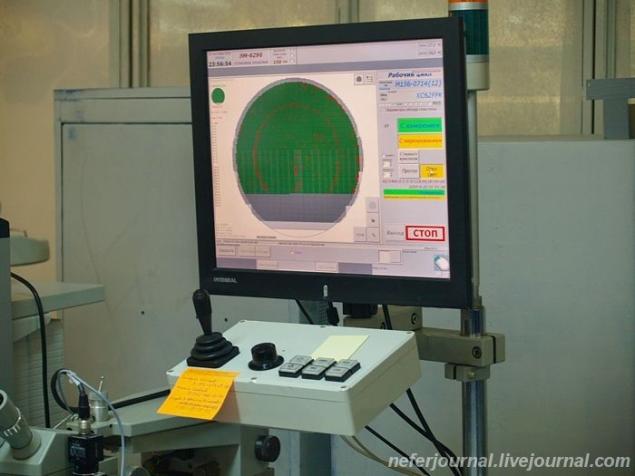

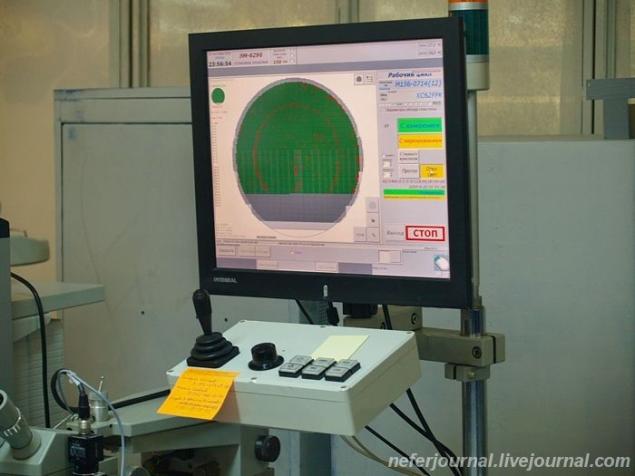

On the computer screen displays the testing process. Red marked unusable sector, gray - something that has not been tested. Bad sectors are usually arranged randomly, if traced some regularity (stripe or a circle for example), it is an occasion to test and tweak something in technology.

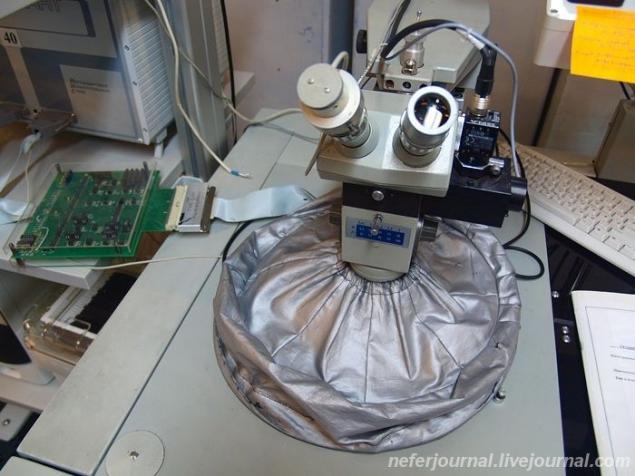

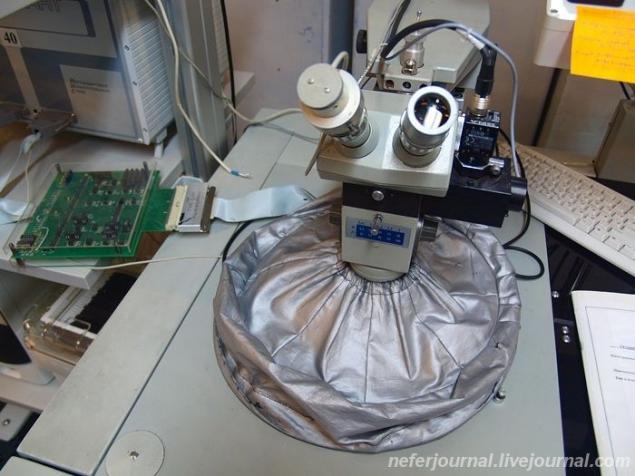

Under the hood is this drive that is tested. If you look through a microscope, the four corners of the square touch needles and jump to the next. During this touching robot determines suitability. And the needles should be strictly on the same level, they are adjusted exactly to some sort of share millimeters. Imagine what it's size, if all this can only be seen under a microscope. Nanotechnology!

via Source

Originally silicon looks like. He is a natural semiconductor.

First there was a silicon chip :) This is the foundation.

Silicon is melted in a silicon rod is inserted, then the mass of molten silicon cools and crystallizes around this core.

Cylinder "shred" on thin layers

Then some parts of etching acid and turns is such a blank

And this is a blank for metrobiletov, they're lying on the table, decided to take a picture. On the "Micron" make transportation, discount, payment, social insurance and medical records, as well as ski passes and passport chip. And all this is done is called a "turnkey", that is, inside and out, a full cycle. This permits control the quality of each stage of production and to improve the degree of security.

We go through an underpass on the production

Here are the most nedobiletiki. This workshop takes place the so-called assembly inlays.

If you look closely, you will notice that this is already zagotovochke flyspeck posed robot

Here, in this booth and robot puts this flyspecked chip. Generally in the shops there is something incomprehensible, each machine is divided into these cabins, in each cabin sits robot and does its job. Then it all moves to the next booth. I looked at some, watched them and did not understand anything.

But here it is clear to me - a single ticket for November! A pair of coils tickets :)

Here are assembled tickets

Uncle changed roll, this is ready

These pieces are sealed in a synthetic shell, similar to the paper, it is resistant to tearing and mechanical damage, with all the cost of the final product using this technology below the cost of plastic counterparts.

Go to the next shop

Now, from ready-tickets, we take a few steps back to that same plate, which is cut off from the silicon cylinder. Despite the fact that the plate is thin, it is necessary to make it Tonci. This process is called - thinning. This is done as robots inside the chamber, one robot picks up the plate and delivers another robot, which puts it on a special drive where necking occurs.

Here he put the disc to the next robot took her

Here, the second robot just takes drive, has not been able to catch this moment

When we watched the thinning noticed that there is some kind of liquid. It reminded me of a pancake, hissing and shkvorchaschy on oil. Of course it was not oil, said it deionized water.

This exhaust disc. Small squares area of less than 1 square. mm - it chips. I understand this RFID-chips (Radio Frequency IDentification - RFID) used just as contactless smart cards of the Moscow metro.

Memory photo

Here comes the test. Some manufacturers have already tested the final product, on the "Micron" as there is such a intermediate control, very radeyut for quality.

On the computer screen displays the testing process. Red marked unusable sector, gray - something that has not been tested. Bad sectors are usually arranged randomly, if traced some regularity (stripe or a circle for example), it is an occasion to test and tweak something in technology.

Under the hood is this drive that is tested. If you look through a microscope, the four corners of the square touch needles and jump to the next. During this touching robot determines suitability. And the needles should be strictly on the same level, they are adjusted exactly to some sort of share millimeters. Imagine what it's size, if all this can only be seen under a microscope. Nanotechnology!

via Source