1221

Micron plant. Part 2.

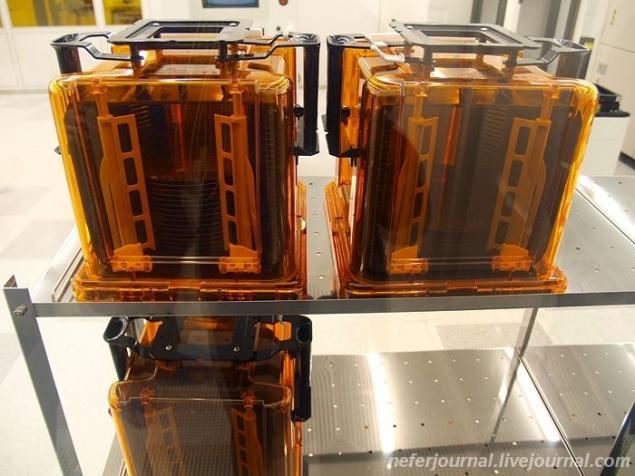

The factory "Micron" in terms of technology and equipment is the most advanced microelectronic enterprise in Russia. It is the largest manufacturer of semiconductor products in the CIS and Eastern Europe. The company produces more than 500 kinds of chips and semiconductor products. 20% is exported. Production is delivered even in China, which is very surprising. "Micron" part of the group "Sitronics", which cooperates with the Franco-Italian company ST Microelectronics (STM). In 2007, was equipped with a so-called "clean room" is a sterile area for the production of microchips and electronic chips. I invite you to look into a unique place.

Part 1 here.

In this room are all conditions that do not fall to dust, germs and other particles. Air is reversed for 30 seconds. In the case of disconnection from the power supply switched on the emergency generator.

Entrance to the "clean room" is allowed only in a special suit. Change lasts from 8 to 12 hours. We were at night. Observing from the buffer zone.

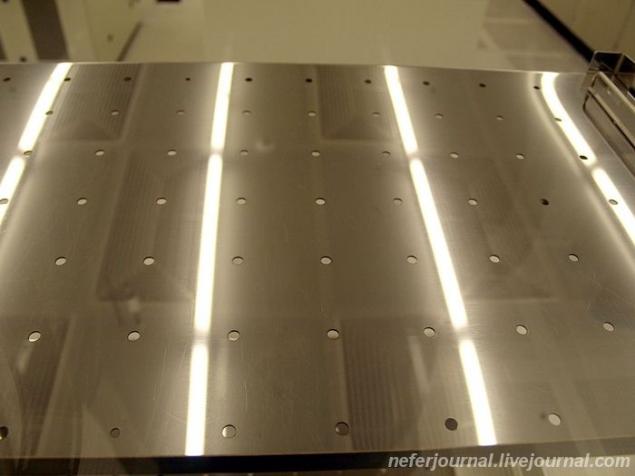

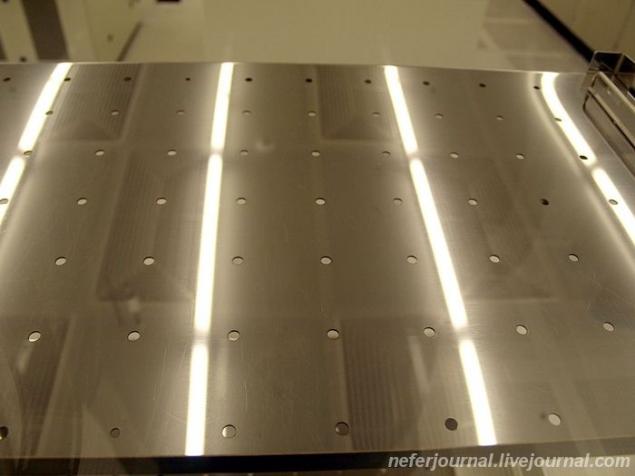

Hole in the table and in the floor allow air to circulate freely and to avoid unnecessary turbulence. The ceiling consists of air conditioning and the air flow is continuous from top to bottom.

In the buffer zone of the floor as "full of holes." We went to a "clean room" on the perimeter.

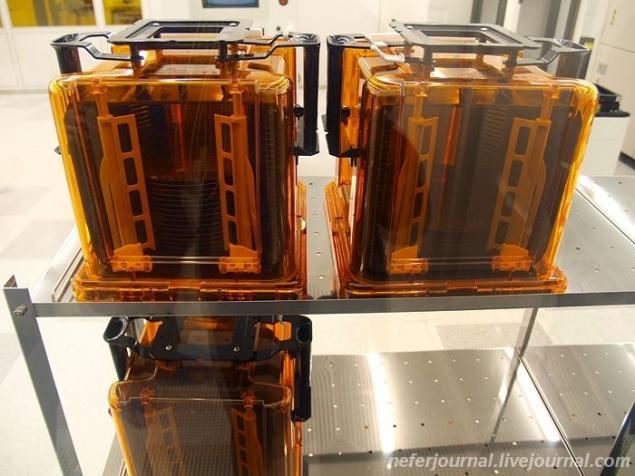

Orange tape. There are still white. Designed for a variety of purposes.

Table with holes. By the way, the objects in the "clean room" can not be moved, you can only swap.

The pressure in this room is a little higher, no germs, all this is not very good for human health, but the production is not considered harmful

A giant elevator! We're going down. Elevator rides so smoothly that the movement is not felt. They said that this is important. And the floor of the elevator floor combined with floor to within a millimeter.

On one of the depots were barrels with an acid, and the ceiling were pipe, which are hydrogen peroxide, potassium hydroxide, nitric acid, hydrofluoric acid, sulfuric acid. I immediately introduced thriller with elements of horror movies :)

The room for the preparation of deionized water

2, 7 liters of plain water is obtained 1 liter of deionized. Here in this post actually all white and happening.

To ensure the 1 m "clean room" should be 5-10 m ancillary facilities. That is, if the area "clean room" is 2,000 square meters. m, the more than 10 000 sq. m engaged in manufacturing, service them.

That's something we talk. I'm a deaf ear, to be honest, I was so impressed, and then there's all sorts of tubes range of hazardous substances.

Hydrofluoric acid - a terrible thing!

In my opinion koloritnenko - hoses and tubes. All this around and everywhere, right, left, above his head. Marked only track on which you can navigate.

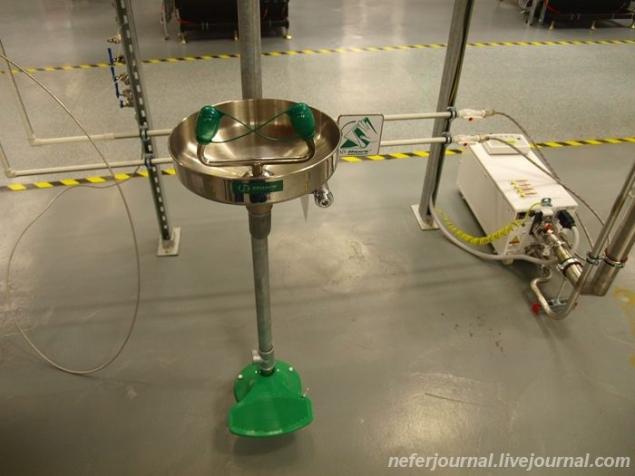

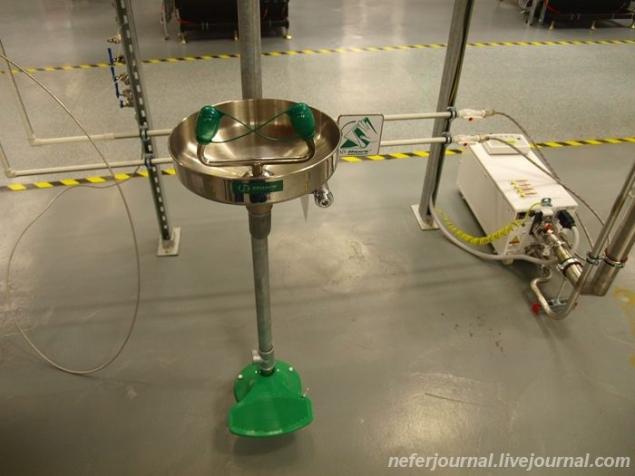

Emergency shower

Emergency washbasin

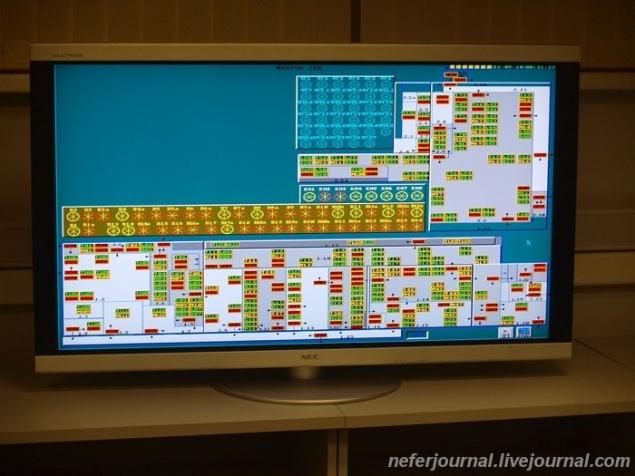

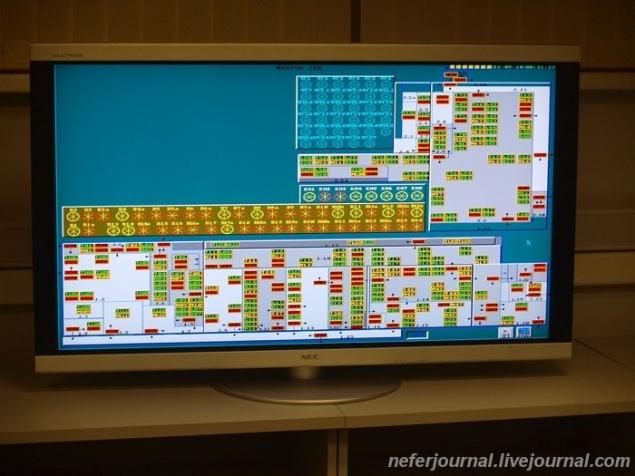

Computer room, where the management of all these systems

Go to the entrance of "clean room". The first thing that occurs is a sticky mat.

Here employees dress up in their costumes antistatic. I remember something about the fabric using carbon fiber. Generally had a bunch of information, was not able to remember everything.

After fifty washes suit debited

Entrance to the 'clean room'. There is a glass sealed compartment, in which the blowing clean air.

Benches placed in a special way to get into the clean zone could only stepped over her

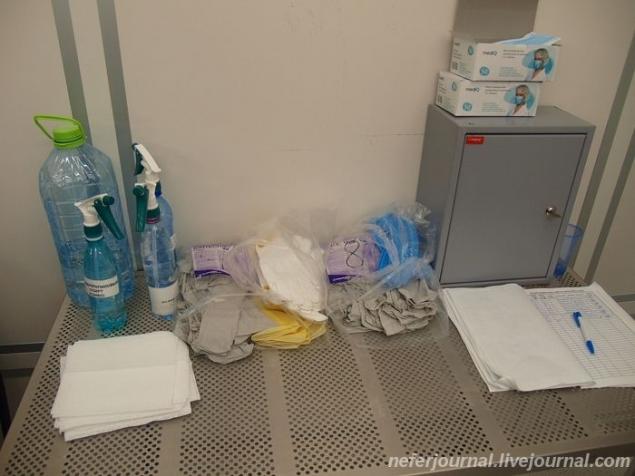

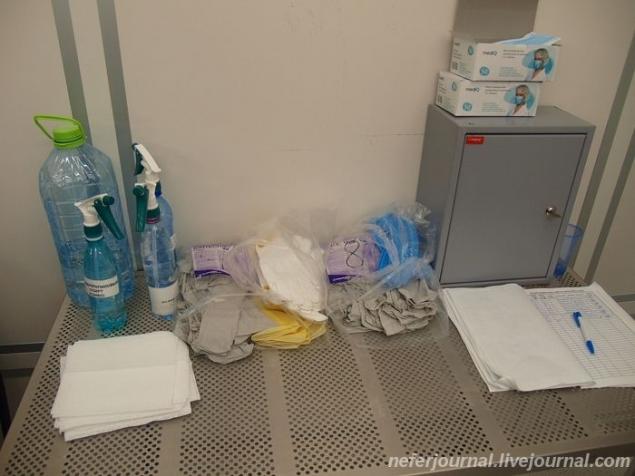

Any auxiliary gadgets: isopropyl alcohol, gloves, anti-static cloth, masks, hats

That's just one of the workers over the change. We watched with interest as a caterpillar turns into a butterfly emerges from the jumpsuit man.

Then one of the members of our group volunteered to try a special suit for yourself. Dress start to head to the dust and other particles do not fall on the suit. The hair under the cap removed.

Then he puts on a mask. Smoking at work are very reluctant to accept, even said that they try not to hire smokers. But sometimes that is already running suddenly acquire an addiction. These people wear two masks. Also, according to the norms of production workers should be without makeup.

The last stage - shoes. One wears boots and leg spread to clean territory.

Then the same thing with the second leg. Back in the same order.

There is a mirror and a picture of him. You can look at yourself in front of the "clean room" to check all the details of the appearance.

Straight Gagarin pancake :)

But he was allowed only to sniff the air "clean room» :)

A few more facts and details. In everyday life we are surrounded by about 300 chips. Computers, calculators, mobile cooler with water, air conditioning and other devices - all contain chips. Here - 30, where - 25, eventually accumulates numeral 300 is an average. Last year, in partnership with state corporation RUSNANO and the Franco-Italian company STMicroelectronics launched a project to create a production line of integrated circuits based on nanoelectronic technology with design rules of 90 nm on 200 mm wafers. It is even smaller, respectively, than the technology 180. Microchip 180 nanometers in size - is the topological level of 0, 18 micron, 90 nanometer - 0, 09 micron, I now know. A nanometer is less than a millimeter a million times! Provide all difficult. In an ordinary microscope not make out even need a special device. If everything will be developed further at about the same pace as now, then in 15 years the transistors on a chip is the same as the neurons in the human brain. The Japanese people are advanced in the field of electronics, they invented the exoskeleton. This special frame to increase muscular strength of man. All this of course is still imperfect, still are being improved and research, but for people with disabilities (problems with the musculoskeletal system) is simply salvation. Also it is developing devices to restore vision. That is roughly the visible image recoding clear mogza code. People with "artificial vision" distinguish muddy paths, though the image is perceived as black and white. But it is still better than blindness.

via source

Part 1 here.

In this room are all conditions that do not fall to dust, germs and other particles. Air is reversed for 30 seconds. In the case of disconnection from the power supply switched on the emergency generator.

Entrance to the "clean room" is allowed only in a special suit. Change lasts from 8 to 12 hours. We were at night. Observing from the buffer zone.

Hole in the table and in the floor allow air to circulate freely and to avoid unnecessary turbulence. The ceiling consists of air conditioning and the air flow is continuous from top to bottom.

In the buffer zone of the floor as "full of holes." We went to a "clean room" on the perimeter.

Orange tape. There are still white. Designed for a variety of purposes.

Table with holes. By the way, the objects in the "clean room" can not be moved, you can only swap.

The pressure in this room is a little higher, no germs, all this is not very good for human health, but the production is not considered harmful

A giant elevator! We're going down. Elevator rides so smoothly that the movement is not felt. They said that this is important. And the floor of the elevator floor combined with floor to within a millimeter.

On one of the depots were barrels with an acid, and the ceiling were pipe, which are hydrogen peroxide, potassium hydroxide, nitric acid, hydrofluoric acid, sulfuric acid. I immediately introduced thriller with elements of horror movies :)

The room for the preparation of deionized water

2, 7 liters of plain water is obtained 1 liter of deionized. Here in this post actually all white and happening.

To ensure the 1 m "clean room" should be 5-10 m ancillary facilities. That is, if the area "clean room" is 2,000 square meters. m, the more than 10 000 sq. m engaged in manufacturing, service them.

That's something we talk. I'm a deaf ear, to be honest, I was so impressed, and then there's all sorts of tubes range of hazardous substances.

Hydrofluoric acid - a terrible thing!

In my opinion koloritnenko - hoses and tubes. All this around and everywhere, right, left, above his head. Marked only track on which you can navigate.

Emergency shower

Emergency washbasin

Computer room, where the management of all these systems

Go to the entrance of "clean room". The first thing that occurs is a sticky mat.

Here employees dress up in their costumes antistatic. I remember something about the fabric using carbon fiber. Generally had a bunch of information, was not able to remember everything.

After fifty washes suit debited

Entrance to the 'clean room'. There is a glass sealed compartment, in which the blowing clean air.

Benches placed in a special way to get into the clean zone could only stepped over her

Any auxiliary gadgets: isopropyl alcohol, gloves, anti-static cloth, masks, hats

That's just one of the workers over the change. We watched with interest as a caterpillar turns into a butterfly emerges from the jumpsuit man.

Then one of the members of our group volunteered to try a special suit for yourself. Dress start to head to the dust and other particles do not fall on the suit. The hair under the cap removed.

Then he puts on a mask. Smoking at work are very reluctant to accept, even said that they try not to hire smokers. But sometimes that is already running suddenly acquire an addiction. These people wear two masks. Also, according to the norms of production workers should be without makeup.

The last stage - shoes. One wears boots and leg spread to clean territory.

Then the same thing with the second leg. Back in the same order.

There is a mirror and a picture of him. You can look at yourself in front of the "clean room" to check all the details of the appearance.

Straight Gagarin pancake :)

But he was allowed only to sniff the air "clean room» :)

A few more facts and details. In everyday life we are surrounded by about 300 chips. Computers, calculators, mobile cooler with water, air conditioning and other devices - all contain chips. Here - 30, where - 25, eventually accumulates numeral 300 is an average. Last year, in partnership with state corporation RUSNANO and the Franco-Italian company STMicroelectronics launched a project to create a production line of integrated circuits based on nanoelectronic technology with design rules of 90 nm on 200 mm wafers. It is even smaller, respectively, than the technology 180. Microchip 180 nanometers in size - is the topological level of 0, 18 micron, 90 nanometer - 0, 09 micron, I now know. A nanometer is less than a millimeter a million times! Provide all difficult. In an ordinary microscope not make out even need a special device. If everything will be developed further at about the same pace as now, then in 15 years the transistors on a chip is the same as the neurons in the human brain. The Japanese people are advanced in the field of electronics, they invented the exoskeleton. This special frame to increase muscular strength of man. All this of course is still imperfect, still are being improved and research, but for people with disabilities (problems with the musculoskeletal system) is simply salvation. Also it is developing devices to restore vision. That is roughly the visible image recoding clear mogza code. People with "artificial vision" distinguish muddy paths, though the image is perceived as black and white. But it is still better than blindness.

via source