1721

How to make potato chips

It is believed that the chips were more than 150 years ago in the United States. Legend has it that one of the elite American restaurants, the client (railroad magnate Vanderbilt) did not like the restaurant's signature dish, "French fries" and he returned it to the kitchen, with the claim that the potato is too thick. The chef decided to play a trick on the client and the sliced potatoes on thin slices and fry in butter to the table. Surprisingly, the customer really liked the dish, and since then the restaurant menu, a new dish - potato chips. Chips & quot; **** & quot; produced since 1938. Today the company & quot; ******** & quot; It is a leading manufacturer of salty snacks both in the world and in Russia. Delivery of chips & quot; *** & quot; in Russia began in the mid-90s.

The theme of today's reportage - plant of the company & quot; ***** & quot; for the production of potato chips & quot; *** & quot ;, recently opened in the city of Azov, Rostov Region. In addition, the plant produces crackers Hrusteam. Walk along the series production line and will consider it in detail.

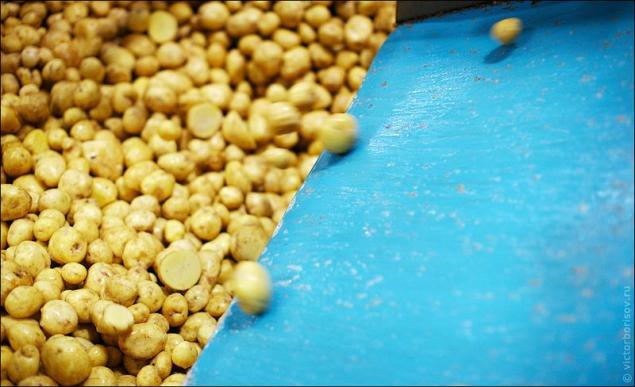

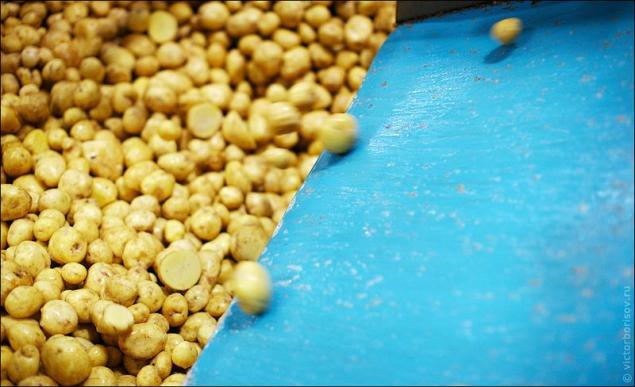

Every day here is unloaded nine 20-ton truck with potatoes. Potatoes on the conveyor belt gets into the washing machine, which is used to clean the water recirculation. Anything in the world, there are three such automatic car wash. The washing process is physically impossible to remove all takes place in a closed container. After washing the potatoes supplied to the temporary storage bins - special containers where supplied as necessary for the production.

Before tubers fall into a special machine for cutting, the inspector visually inspect the tubers going over the tape, and if necessary remove any visible defects.

By the way: For the production of chips suitable not any potato. There are so-called chipsovye potato varieties that contain high starch.

All employees periodically undergo medical examination and have the medical records, it is done so that people did not get sick on the production. In addition, the entrance to the shop, all must wash their hands.

Cleaning takes place potatoes in abrasive drums batch. First, there is a loading required amount of potatoes in a weight hopper, this occurs after unloading the drum.

Just cutting takes place mechanically by the rotation of the cone-shaped bottom of the drum. Inside, cutting machines, eight pairs of sharp blades that cut the tuber into thin slices. The thickness of each slice of less than two millimeters.

After cutting the potato slices enter the very "heart" of the production line of potato chips - frying bath for frying slices and obtaining basic chips. This equipment, which has no analogues, was created specifically for the plant & quot; ***** & quot; and you can not show it.

Thinly sliced potatoes come in a bath of oil, which are fried for three minutes at 180 degrees Celsius. High-quality oil, as well as high-quality potatoes - the basis of the taste of potato chips.

The plant was improved formulation using a special mixture of vegetable oils, including sunflower oil vysokoolinovogo domestic production, whereby a 25% reduced saturated fat content in the final product.

Every day, the plant being tested quality. Check how basic chips, just coming out of the furnace and completely wrapped packages.

At this stage, the potato chips fried added special aromatic and flavoring additives, which are based salt.

Simultaneously, the line can be a production of three flavors.

By the way: The plant is designed to produce 50 thousand tons of finished products per year. What a fantastic figure, in my opinion.

For three conveyors come ready-made chips to packaging. First, there is a distribution and weighting.

By the way: Please note that the entire length of the line are very few employees. It uses advanced equipment, which works fully automatically. In addition, it is important that as little as possible people in contact with the finished product.

Weight machines weigh multiple portions and calculating the best combination of weight, which has the exact weight in order to conform to the standard and specified on the package weight.

If we consider that the net weight of a pack is 28 grams, you can imagine the accuracy of hardware settings.

The weighted portion is discharged to the packaging line.

Portion control passes to the presence of impurities (metal detector) and into the package, which by this time developed the packaging machine of packaging (foil). Before zapajkoj seam in the package supplied food nitrogen, which enables the desired shelf life of the product. Weighing and packing equipment operates simultaneously, at speeds up to 80 bags per minute.

Packed bag of chips supplied to operators who manually folded bags in cardboard boxes.

Boxes with chips stacked on pallets and transported to the warehouse.

In parallel, there is line for production of crackers

A mixture of flour and water is fed into the extruder, heated and mixed thoroughly. From the extruder crackers come in the form of bundles, which are cut to size by rotating knives.

The next step crackers are dried in the oven and hit the land application of condiments.

The packaging line is the same, which produce chips.

Weighing takes place in similar weighting machine which generates several portions and selects the best combination for the sealing of a package.

Ready-made crackers.

Performance line - 12 tons of finished products per day.

Employees are not allowed to wear watches and jewelery, forbidden manicures and artificial nails, the hair must be covered with netting, so that nothing got in the pipeline.

In addition to taste and visual matching slices of accepted standards, there is check the quality of packaging. The seam should be flat and opened a packet traffic should be exactly along the seam without gaps.

The staff of the factory. By the way, the production line is working round the clock in three shifts.

The appearance of the plant.

Bon appetit!

via bigpicture.ru

The theme of today's reportage - plant of the company & quot; ***** & quot; for the production of potato chips & quot; *** & quot ;, recently opened in the city of Azov, Rostov Region. In addition, the plant produces crackers Hrusteam. Walk along the series production line and will consider it in detail.

Every day here is unloaded nine 20-ton truck with potatoes. Potatoes on the conveyor belt gets into the washing machine, which is used to clean the water recirculation. Anything in the world, there are three such automatic car wash. The washing process is physically impossible to remove all takes place in a closed container. After washing the potatoes supplied to the temporary storage bins - special containers where supplied as necessary for the production.

Before tubers fall into a special machine for cutting, the inspector visually inspect the tubers going over the tape, and if necessary remove any visible defects.

By the way: For the production of chips suitable not any potato. There are so-called chipsovye potato varieties that contain high starch.

All employees periodically undergo medical examination and have the medical records, it is done so that people did not get sick on the production. In addition, the entrance to the shop, all must wash their hands.

Cleaning takes place potatoes in abrasive drums batch. First, there is a loading required amount of potatoes in a weight hopper, this occurs after unloading the drum.

Just cutting takes place mechanically by the rotation of the cone-shaped bottom of the drum. Inside, cutting machines, eight pairs of sharp blades that cut the tuber into thin slices. The thickness of each slice of less than two millimeters.

After cutting the potato slices enter the very "heart" of the production line of potato chips - frying bath for frying slices and obtaining basic chips. This equipment, which has no analogues, was created specifically for the plant & quot; ***** & quot; and you can not show it.

Thinly sliced potatoes come in a bath of oil, which are fried for three minutes at 180 degrees Celsius. High-quality oil, as well as high-quality potatoes - the basis of the taste of potato chips.

The plant was improved formulation using a special mixture of vegetable oils, including sunflower oil vysokoolinovogo domestic production, whereby a 25% reduced saturated fat content in the final product.

Every day, the plant being tested quality. Check how basic chips, just coming out of the furnace and completely wrapped packages.

At this stage, the potato chips fried added special aromatic and flavoring additives, which are based salt.

Simultaneously, the line can be a production of three flavors.

By the way: The plant is designed to produce 50 thousand tons of finished products per year. What a fantastic figure, in my opinion.

For three conveyors come ready-made chips to packaging. First, there is a distribution and weighting.

By the way: Please note that the entire length of the line are very few employees. It uses advanced equipment, which works fully automatically. In addition, it is important that as little as possible people in contact with the finished product.

Weight machines weigh multiple portions and calculating the best combination of weight, which has the exact weight in order to conform to the standard and specified on the package weight.

If we consider that the net weight of a pack is 28 grams, you can imagine the accuracy of hardware settings.

The weighted portion is discharged to the packaging line.

Portion control passes to the presence of impurities (metal detector) and into the package, which by this time developed the packaging machine of packaging (foil). Before zapajkoj seam in the package supplied food nitrogen, which enables the desired shelf life of the product. Weighing and packing equipment operates simultaneously, at speeds up to 80 bags per minute.

Packed bag of chips supplied to operators who manually folded bags in cardboard boxes.

Boxes with chips stacked on pallets and transported to the warehouse.

In parallel, there is line for production of crackers

A mixture of flour and water is fed into the extruder, heated and mixed thoroughly. From the extruder crackers come in the form of bundles, which are cut to size by rotating knives.

The next step crackers are dried in the oven and hit the land application of condiments.

The packaging line is the same, which produce chips.

Weighing takes place in similar weighting machine which generates several portions and selects the best combination for the sealing of a package.

Ready-made crackers.

Performance line - 12 tons of finished products per day.

Employees are not allowed to wear watches and jewelery, forbidden manicures and artificial nails, the hair must be covered with netting, so that nothing got in the pipeline.

In addition to taste and visual matching slices of accepted standards, there is check the quality of packaging. The seam should be flat and opened a packet traffic should be exactly along the seam without gaps.

The staff of the factory. By the way, the production line is working round the clock in three shifts.

The appearance of the plant.

Bon appetit!

via bigpicture.ru