1559

Foil - a delicate matter

Aluminum spoons and forks, we do not eat for a long time, but there is a material that is still in vogue, and he was constantly in front of our eyes, the hands, on the dining table. This foil. Those wonderful shiny paper that a child was so cool smooth finger, eating candy or chocolate. The girls made of foil their "secrets", and the boys from the twisted wrappers "cartridges" for the slingshot. Aluminum foil is still one of the most commonly used materials in food production, electrical, pharmaceutical and automotive industries. It has an ideal thermal conductivity, hygienic, comfortable and, most importantly, amazingly friendly - came out of the ground, hitting back after use, disappears without a trace.

To produce aluminum foil, it is necessary to build a plant with smelters and rolling machines, rolling ingot of aluminum in the thinnest sheet thickness of up to 5 microns. In 1993 a factory was built next to the Sayanogorsk aluminum smelter, which I wrote in the previous report. With this SAZU helped the Italian company FATA, which manufactures equipment for rolled aluminum and the American Reynolds Metals Company, a world leader in the production of packaging materials based on aluminum.

The result is a modern enterprise with complete production cycle - from the preparation of the melt to produce foil and packaging materials based on it. Now the factory is part of the structure of RUSAL produces about 70 percent of domestic foil. Rolls foil that housewives are buying in a store, yogurt covers, wrappers for chocolate, cheese curds, candy wrappers for candy, cigarette packaging, etc. - All this is on SAYaNALe.

It all begins here, in the melting shop enterprise. These come from the factory SAL conveyors with buckets of molten "primary" aluminum and pour it in the oven. Prepared in the melting furnace melt degassing takes place with the addition of an additional modifier for grinding grain and improve the structure of cast billets.

Thus prepared melt is supplied to the apparatus and continuous casting "superkaster", which is produced using the tape thickness of 6-10 mm and a width of 1200-1650 mm. From it, and will be rolled foil.

Aluminum tape is still hot, twisted in large rolls and is waiting for their turn to rental.

But rental harvested feed is not immediately apparent. First she enters the kiln, wherein in a nitrogen atmosphere is heated again to recover crystal lattice in the metal - it must withstand high loads and at a pressure not to break.

Finished aluminum tape supplied to the mill.

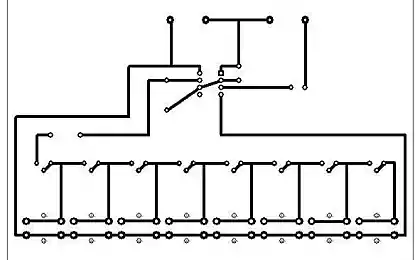

The shop has more than cold-rolled aluminum «FATA Hunter». With each pass through the mill aluminum tape becomes thinner.

The production of foil in performance sports, there is a struggle for material thickness reduction micrometer, as well as athletes improve their results in running, e.g., competing for tenths of seconds. SAYANAL began with the release of 11-micron foil, and gradually gaining experience, the transition to more subtle forms of material. After modernization, which is carried out together with the German company «Achenbach», on SAYaNALe began to produce a foil thickness of 5 microns (for comparison - the thickness of a human hair 40-50 microns). This foil is used for the production of capacitors, special aluminum strips for the production of wall panels, multi-layer composite material for sealing containers for food products.

After the tape becomes very thin, the two webs are brought together and rolled for one time. The process of cold rolling followed by a high number of water-oil mixture.

Striking as the tape a few microns thick, rushing through the press rolls at a tremendous speed, not torn. Rather, it tears sometimes, but it's state of emergency, which is very rare.

After the two webs of foil rolled together, one side of her turns matt and shiny flip. Razyal the thinnest material in two parts easy.

Now we need to once again make a roll with two separate dual foil and cut them at the same time for a given width. Thereafter the rolls of foil again fired furnaces. Virtually waste-free production - all that remains is pressed again and goes into the melting furnace.

Ready and cut foil comes to packaging, and the part intended for further processing, are sent to the Department of converting, which produces lamination (sticker foil to the substrate - paper, for example), lamination, gravure printing, varnishing, painting and stamping foil and combined packaging materials based on it.

On SAYaNALe are here are giant vosmisektsionnye gravure printing foil.

The factory not only make printing plates, but independently develop packaging design for customers.

Before printing a test sample of the material is taken.

Here everything, as in conventional printing, but instead of paper - aluminum foil.

From the press release:

"The product range is quite wide - smooth, printed, laminated foils for the tobacco industry and food packaging, foil colored, embossed with termolakovym coating, etc.. More than half of the plant's production is exported - to the USA, Western and Eastern Europe, Middle East in Africa and in Australia (in 46 countries on 5 continents). Foil packaging and combined based materials possess a number of advantages compared with other materials of high of flavor, gas and opacity, the ability to heat ray reflection and shaping, good heat resistance, impact resistance, when the possibility of using heat, aseptic processing and sterilization. Foreign consumers are most interested in home delivery and smooth foil for the manufacture of composite materials. In the Russian market products Sayan use food and tobacco processing, pharmaceuticals, construction and cable industries. More than 350 enterprises in 40 regions of Russia are used in its production of foil and packaging materials, custom SAYaNALe »

There are problems, of course. Heavily pressured prices, Chinese manufacturers foil. If the traditional confectionery brands still pack a sweet product in real foil, confectioners in the province, trying to reduce the cost of production, are increasingly moving to all sorts of substitutes, polyethylene and the like. Vehicles are not happy constant increase in transportation tariffs. But Siberians hold brand, modernizing production, reduce their costs, compete with the help of high quality. In short, working. Think about them when you see on the packaging foil inscription "Sayan" - now you know where it makes.

Source: drugoi.livejournal.com

To produce aluminum foil, it is necessary to build a plant with smelters and rolling machines, rolling ingot of aluminum in the thinnest sheet thickness of up to 5 microns. In 1993 a factory was built next to the Sayanogorsk aluminum smelter, which I wrote in the previous report. With this SAZU helped the Italian company FATA, which manufactures equipment for rolled aluminum and the American Reynolds Metals Company, a world leader in the production of packaging materials based on aluminum.

The result is a modern enterprise with complete production cycle - from the preparation of the melt to produce foil and packaging materials based on it. Now the factory is part of the structure of RUSAL produces about 70 percent of domestic foil. Rolls foil that housewives are buying in a store, yogurt covers, wrappers for chocolate, cheese curds, candy wrappers for candy, cigarette packaging, etc. - All this is on SAYaNALe.

It all begins here, in the melting shop enterprise. These come from the factory SAL conveyors with buckets of molten "primary" aluminum and pour it in the oven. Prepared in the melting furnace melt degassing takes place with the addition of an additional modifier for grinding grain and improve the structure of cast billets.

Thus prepared melt is supplied to the apparatus and continuous casting "superkaster", which is produced using the tape thickness of 6-10 mm and a width of 1200-1650 mm. From it, and will be rolled foil.

Aluminum tape is still hot, twisted in large rolls and is waiting for their turn to rental.

But rental harvested feed is not immediately apparent. First she enters the kiln, wherein in a nitrogen atmosphere is heated again to recover crystal lattice in the metal - it must withstand high loads and at a pressure not to break.

Finished aluminum tape supplied to the mill.

The shop has more than cold-rolled aluminum «FATA Hunter». With each pass through the mill aluminum tape becomes thinner.

The production of foil in performance sports, there is a struggle for material thickness reduction micrometer, as well as athletes improve their results in running, e.g., competing for tenths of seconds. SAYANAL began with the release of 11-micron foil, and gradually gaining experience, the transition to more subtle forms of material. After modernization, which is carried out together with the German company «Achenbach», on SAYaNALe began to produce a foil thickness of 5 microns (for comparison - the thickness of a human hair 40-50 microns). This foil is used for the production of capacitors, special aluminum strips for the production of wall panels, multi-layer composite material for sealing containers for food products.

After the tape becomes very thin, the two webs are brought together and rolled for one time. The process of cold rolling followed by a high number of water-oil mixture.

Striking as the tape a few microns thick, rushing through the press rolls at a tremendous speed, not torn. Rather, it tears sometimes, but it's state of emergency, which is very rare.

After the two webs of foil rolled together, one side of her turns matt and shiny flip. Razyal the thinnest material in two parts easy.

Now we need to once again make a roll with two separate dual foil and cut them at the same time for a given width. Thereafter the rolls of foil again fired furnaces. Virtually waste-free production - all that remains is pressed again and goes into the melting furnace.

Ready and cut foil comes to packaging, and the part intended for further processing, are sent to the Department of converting, which produces lamination (sticker foil to the substrate - paper, for example), lamination, gravure printing, varnishing, painting and stamping foil and combined packaging materials based on it.

On SAYaNALe are here are giant vosmisektsionnye gravure printing foil.

The factory not only make printing plates, but independently develop packaging design for customers.

Before printing a test sample of the material is taken.

Here everything, as in conventional printing, but instead of paper - aluminum foil.

From the press release:

"The product range is quite wide - smooth, printed, laminated foils for the tobacco industry and food packaging, foil colored, embossed with termolakovym coating, etc.. More than half of the plant's production is exported - to the USA, Western and Eastern Europe, Middle East in Africa and in Australia (in 46 countries on 5 continents). Foil packaging and combined based materials possess a number of advantages compared with other materials of high of flavor, gas and opacity, the ability to heat ray reflection and shaping, good heat resistance, impact resistance, when the possibility of using heat, aseptic processing and sterilization. Foreign consumers are most interested in home delivery and smooth foil for the manufacture of composite materials. In the Russian market products Sayan use food and tobacco processing, pharmaceuticals, construction and cable industries. More than 350 enterprises in 40 regions of Russia are used in its production of foil and packaging materials, custom SAYaNALe »

There are problems, of course. Heavily pressured prices, Chinese manufacturers foil. If the traditional confectionery brands still pack a sweet product in real foil, confectioners in the province, trying to reduce the cost of production, are increasingly moving to all sorts of substitutes, polyethylene and the like. Vehicles are not happy constant increase in transportation tariffs. But Siberians hold brand, modernizing production, reduce their costs, compete with the help of high quality. In short, working. Think about them when you see on the packaging foil inscription "Sayan" - now you know where it makes.

Source: drugoi.livejournal.com