814

How does the typography (32 photos)

via victorprofessor

the author writes

Continuing production reports.

This time we went to the publishing and printing complex Itar-Tass. We walk on the production facilities and observe the process. I will try to explain the processes of printing so that it was clear to the simplest man in the street.

All processes in the printing starts from the client department. Namely with the negotiations. The meeting room is simple but very cozy.

Then the managers constitute a technical data sheet print and send the case to the Department of prepress (prepress). Mainly used in printing offset printing. Print this process is slightly different from the usual home and office printers.

First the creation of printing plates. Modern conclusion is made on the technology CTP (computer-to-plate), which facilitates a form for each color component directly from the computer. Here is the output of the unit is engaged in forms.

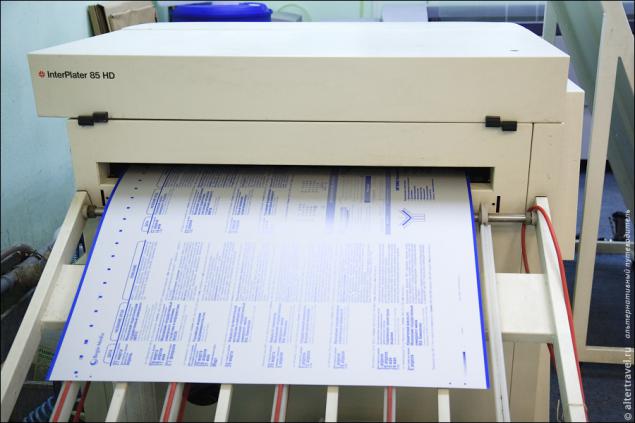

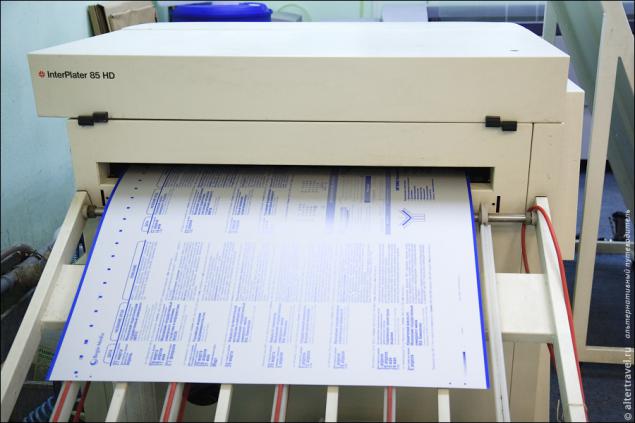

Then the printing plate passes exhibition. Here is the finished form, it consists of a thin aluminum sheet, which is then screwed to the drum of the printing machine.

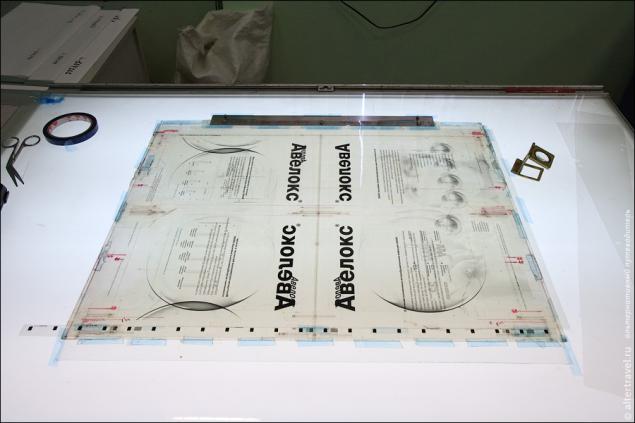

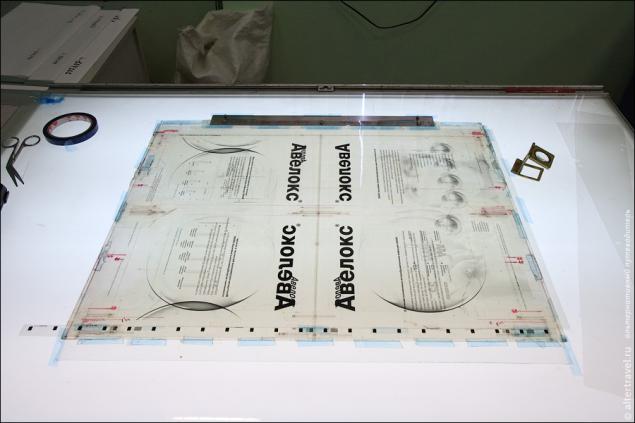

Very near the output produced forms of "antiquated" method. That is the first conclusion made films for each color component (CMYK), and then by hand with a magnifying glass and an adhesive tape is overlapping sheets of special labels. And then the image transfer is performed using a copy machine to the printing plate (approximately the same as the printed photos). As you can see, the process is several times more complicated and labor-intensive technologies CTP.

Then we go to press. Here is the sheet four-color printing machine of the German company Heidelberg MOV-H. There are two such machines. On the right side is a receiving tray. Each section - one color (CMYK = cyan, magenta, yellow, black). Each drum set and secured printing plates.

Then go to the control panel of the unit. It is so to speak the viewing table where the lighting is always present gostirovannoe neutral white light.

Key "ignition" button and information management. That process that is carried out manually by the operator combining films here again be repeated. Because the plate is installed on each reel may be a bit biased, the final image will be printed with disperse colors. For example with the help of these indicators generate fit each plate. As you can see a huge number of printed sheets when such an operation is sent directly into the trash.

Experienced printers can with minimum consumption of paper and ink do makeready on the press. After the fitting is done, the work begins with color. On the magnetic board is usually hung proofing reference for comparison (if any). A densitometer using the measured optical density of color on special scales on the edges of the printed sheet. If a color print of the customer call or printed only on the scales, and relying on the taste of the color printer.

Yellow paint (yellow) to the filler tray. It is reasonable to note that the print production quite toxic and poisonous paint.

This blue color (cyan). During printing, ink flows to the printing plate and then left in those places where to make the so-called notch, and then immediately rolled recording sheet, so desired paint is applied onto the sheet only where "notches."

Nearby stands a small printing machine for black-and-white printing Adast Dominant 725.

A floor below is another modern printing machine company Mitsubishi 3F5. It has 5 sections, which allows you to print in 5 colors (for example, full color + Pantone).

Cans of paint. When printing letterhead or not reproducible CMYK color flowers usually use some additional paint color fan Pantone.

Desktop printing machine. Large format printing and advanced management.

In Japan presses all the inscriptions in English (German - in German).

In the hall where the press is installed an automated system to maintain the desired humidity.

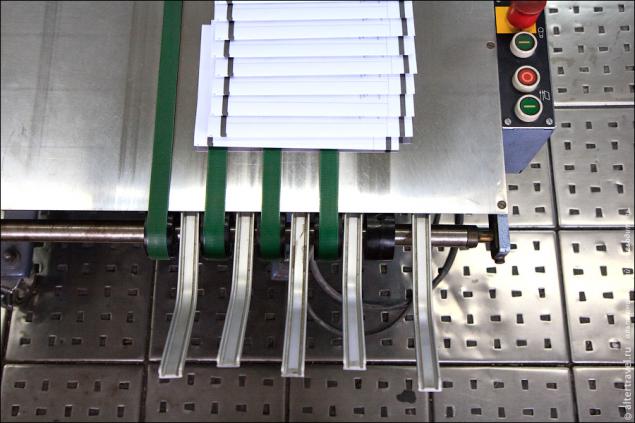

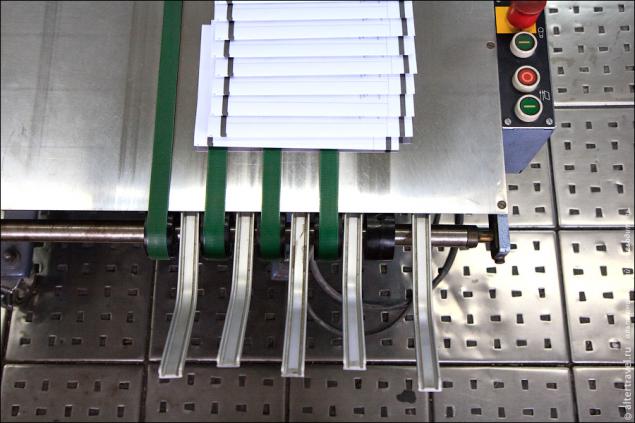

The final section of the printing machine, are mounted receiver for the printed sheets. Powerful fans blow in additional sheets to speed drying.

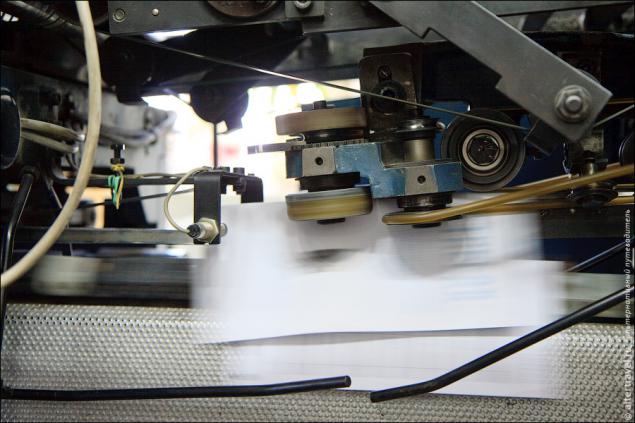

Printing machine - a complex machine and it needs regular maintenance.

Then, after it gets printed products to the shop stitching. There are a variety of machines, each of which is optimized for the specific format of the printed products.

The device performs a simple operation on folding sheets in the finished booklet.

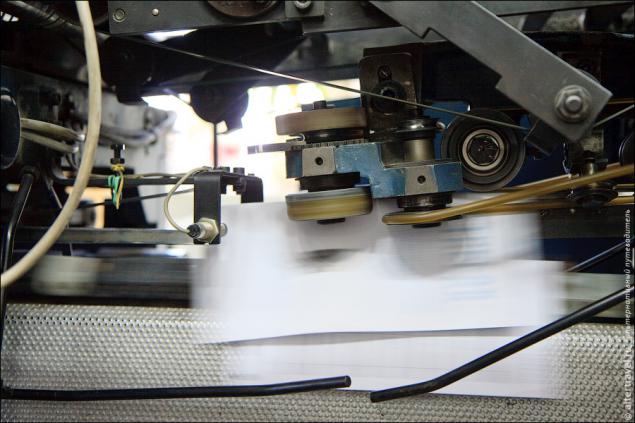

The process is continuously monitored by the operator, are also sometimes be jammed paper.

Stitched products.

There are cell phones and more difficult.

Long conveyor which first gather individual sheets of the booklet, then all closed cover.

And going through a bond. This is not an office stapler, but just two tape wire which is cut and bent into place.

Then the trimming edges.

General view of the shop. Visible as soon as printed products, and fully prepared, packed in paper.

Another conveyor.

And it - cutter. In a single pass of the perfectly straight cuts a stack of sheets of about 8 centimeters.

Apparatus for creasing (folds). Make the folds on a solid paper in the right places.

If required, the finished product can be sealed in foil.

Here manual packing is made of finished products.

Then the products are sent to the warehouse. There are trucks, machines for packaging and one device for lamination.

And from the warehouse finished products supplied to the customer. I note that the print production process is very complicated and records not reveal all the details of production.

Source:

the author writes

Continuing production reports.

This time we went to the publishing and printing complex Itar-Tass. We walk on the production facilities and observe the process. I will try to explain the processes of printing so that it was clear to the simplest man in the street.

All processes in the printing starts from the client department. Namely with the negotiations. The meeting room is simple but very cozy.

Then the managers constitute a technical data sheet print and send the case to the Department of prepress (prepress). Mainly used in printing offset printing. Print this process is slightly different from the usual home and office printers.

First the creation of printing plates. Modern conclusion is made on the technology CTP (computer-to-plate), which facilitates a form for each color component directly from the computer. Here is the output of the unit is engaged in forms.

Then the printing plate passes exhibition. Here is the finished form, it consists of a thin aluminum sheet, which is then screwed to the drum of the printing machine.

Very near the output produced forms of "antiquated" method. That is the first conclusion made films for each color component (CMYK), and then by hand with a magnifying glass and an adhesive tape is overlapping sheets of special labels. And then the image transfer is performed using a copy machine to the printing plate (approximately the same as the printed photos). As you can see, the process is several times more complicated and labor-intensive technologies CTP.

Then we go to press. Here is the sheet four-color printing machine of the German company Heidelberg MOV-H. There are two such machines. On the right side is a receiving tray. Each section - one color (CMYK = cyan, magenta, yellow, black). Each drum set and secured printing plates.

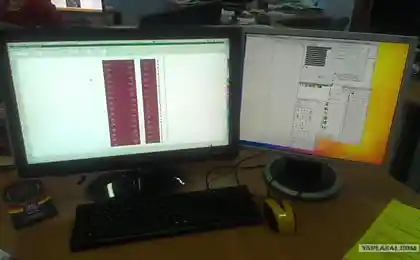

Then go to the control panel of the unit. It is so to speak the viewing table where the lighting is always present gostirovannoe neutral white light.

Key "ignition" button and information management. That process that is carried out manually by the operator combining films here again be repeated. Because the plate is installed on each reel may be a bit biased, the final image will be printed with disperse colors. For example with the help of these indicators generate fit each plate. As you can see a huge number of printed sheets when such an operation is sent directly into the trash.

Experienced printers can with minimum consumption of paper and ink do makeready on the press. After the fitting is done, the work begins with color. On the magnetic board is usually hung proofing reference for comparison (if any). A densitometer using the measured optical density of color on special scales on the edges of the printed sheet. If a color print of the customer call or printed only on the scales, and relying on the taste of the color printer.

Yellow paint (yellow) to the filler tray. It is reasonable to note that the print production quite toxic and poisonous paint.

This blue color (cyan). During printing, ink flows to the printing plate and then left in those places where to make the so-called notch, and then immediately rolled recording sheet, so desired paint is applied onto the sheet only where "notches."

Nearby stands a small printing machine for black-and-white printing Adast Dominant 725.

A floor below is another modern printing machine company Mitsubishi 3F5. It has 5 sections, which allows you to print in 5 colors (for example, full color + Pantone).

Cans of paint. When printing letterhead or not reproducible CMYK color flowers usually use some additional paint color fan Pantone.

Desktop printing machine. Large format printing and advanced management.

In Japan presses all the inscriptions in English (German - in German).

In the hall where the press is installed an automated system to maintain the desired humidity.

The final section of the printing machine, are mounted receiver for the printed sheets. Powerful fans blow in additional sheets to speed drying.

Printing machine - a complex machine and it needs regular maintenance.

Then, after it gets printed products to the shop stitching. There are a variety of machines, each of which is optimized for the specific format of the printed products.

The device performs a simple operation on folding sheets in the finished booklet.

The process is continuously monitored by the operator, are also sometimes be jammed paper.

Stitched products.

There are cell phones and more difficult.

Long conveyor which first gather individual sheets of the booklet, then all closed cover.

And going through a bond. This is not an office stapler, but just two tape wire which is cut and bent into place.

Then the trimming edges.

General view of the shop. Visible as soon as printed products, and fully prepared, packed in paper.

Another conveyor.

And it - cutter. In a single pass of the perfectly straight cuts a stack of sheets of about 8 centimeters.

Apparatus for creasing (folds). Make the folds on a solid paper in the right places.

If required, the finished product can be sealed in foil.

Here manual packing is made of finished products.

Then the products are sent to the warehouse. There are trucks, machines for packaging and one device for lamination.

And from the warehouse finished products supplied to the customer. I note that the print production process is very complicated and records not reveal all the details of production.

Source: