677

Printing house

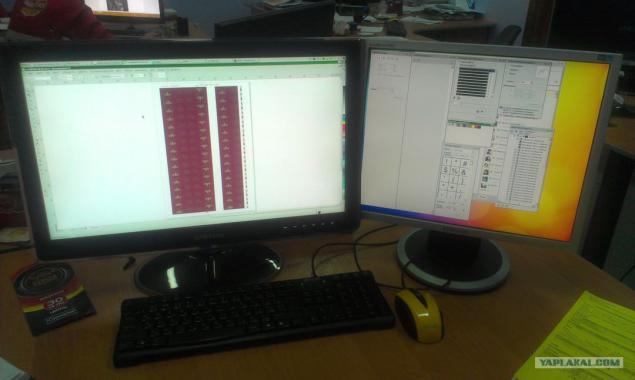

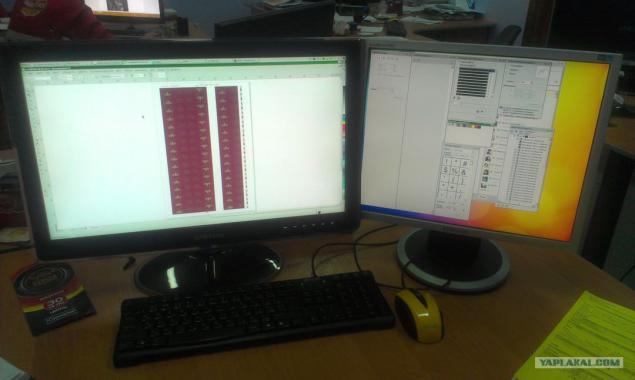

1) my workplace in the department "Design of printed products", owing to prevailing in our region living foundations, the main tool of work SorelDraw. My job is to adjust the received Print layouts, align all operations on products.

It will be about 20 photos

2) The first step in the actual printing process is the conclusion we have aluminum plates. Forms essentially two-layer top coated with a hydrophobic polymer layer (water repellent).

3) This unit (in the background) breaks in the right places this layer by laser, in consequence of that we get a result at the output of the developer:

Now:

4) The essence of offset printing is that the first ordinary water is uniformly applied on the form (moistening), and then there is applied paint, oil-based, and naturally there where the water paint misses, then paint form through rubber shaft is transmitted directly to the sheet Paper

5) And here is the printing machine, or rather where the party already printed sheets go, the way prints 16,000 sheets per hour, and is a 4 second sheet,

6) Remote control of the machine, now all the sensory, and the car is not necessary to go almost exclusively to load the paint, by the way runs on windows vista)

7) It is the very paint, yes, so fill up on top with a spatula.

8) Feed paper into the machine by a plurality of sensors and vacuum

9) cutting machine, runs on windows XP, unfortunately it was off the monitor screen

10) down into the basement, we see platen press, closing his carries two plates embossed with gold or cutting the product of any form

11) interlining machine - gluing unit with cover, mainly used for magazines

12) The application of gloss varnish, UV drying of the left

13) has printing machine caught on the road

14) and another on the windows NT))

15) plant for the production of tubes, tape wound around a steel shaft, top kleetsya label, the main type of use - gift wrapping for alcohol

16) small warehouse with paper rolls

17) finished tubes

With me probably enough

Source:

It will be about 20 photos

2) The first step in the actual printing process is the conclusion we have aluminum plates. Forms essentially two-layer top coated with a hydrophobic polymer layer (water repellent).

3) This unit (in the background) breaks in the right places this layer by laser, in consequence of that we get a result at the output of the developer:

Now:

4) The essence of offset printing is that the first ordinary water is uniformly applied on the form (moistening), and then there is applied paint, oil-based, and naturally there where the water paint misses, then paint form through rubber shaft is transmitted directly to the sheet Paper

5) And here is the printing machine, or rather where the party already printed sheets go, the way prints 16,000 sheets per hour, and is a 4 second sheet,

6) Remote control of the machine, now all the sensory, and the car is not necessary to go almost exclusively to load the paint, by the way runs on windows vista)

7) It is the very paint, yes, so fill up on top with a spatula.

8) Feed paper into the machine by a plurality of sensors and vacuum

9) cutting machine, runs on windows XP, unfortunately it was off the monitor screen

10) down into the basement, we see platen press, closing his carries two plates embossed with gold or cutting the product of any form

11) interlining machine - gluing unit with cover, mainly used for magazines

12) The application of gloss varnish, UV drying of the left

13) has printing machine caught on the road

14) and another on the windows NT))

15) plant for the production of tubes, tape wound around a steel shaft, top kleetsya label, the main type of use - gift wrapping for alcohol

16) small warehouse with paper rolls

17) finished tubes

With me probably enough

Source: