663

How to really make medical equipment in Russia

Prohibiting foreign purchases of medical equipment and consumables, the bill of the Government of the Russian Federation published and will be reviewed. I'm not going to speculate about what the government members do not visit our clinics; of social stratification - to be treated at a private clinic on imported equipment and on our budget - is not going to; even the absence of elementary competitive environment between our vendors, kickbacks and monopolies arising out of this, I will not. There are a variety of opinions, and different sound.

Instead, I'll show you how to actually produce in the Russian medical equipment. I was lucky enough to visit the factory in Kazan, where they make the systems and consumables for endoscopic surgery.

The name of the plant will not be called, that you may have not considered advertising the post or, conversely, to pounce, though, if you want to find it is not difficult, in Kazan only two such production, and even then - they were born out of the collapse of one.

After the overwhelming foreign vidosikov in mind the majority of consumers might get the idea of the coming twenty-first century and nanotechnology. On the scale of large companies and advertising - it is. But a small production, and even aggravated Russian realities, their calculations and planning. In short, who has ever tried to do something on their own perfectly understand what I mean.

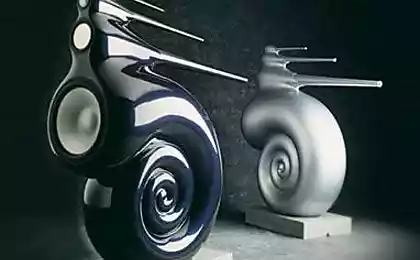

The plant does everything for minimally invasive operations: tools, racks, camera, insufflator and still full of all. The director, it seemed to me a very sincere man, honest talks, saying that it is a copy of the German Storz, but the German is worse, but better than the Chinese, but it is cheaper but, as such a thing is not unique at all ...

That's warehouse. So, one of the shelves. What do you expect to see? A huge hangar with lift trucks? This is not a product that is shipped as a range of M-Video.

This is considered a huge amount. Each piece of hardware - the future endoscopic tool that domestic hospital will buy in the amount of one or two, high prices at tenders, for years to come.

For young people there machines. Cadres no man forges, and those that have - came with the collapse of the plants, even the old school masters.

Is there engineers, quality control technicians, that's all, but it was not a promotional tour blog, because you bore the "mandatory program" photo report is not going to.

According to those who have the equipment I use - it is good, really good tools do. Particularly pleased with customer-oriented, that is suitable for sterilizing equipment archaic systems that are installed in our hospitals, what can be done reusable - is, in contrast to foreign companies, where all one-time maximum.

But I'm not about to say what they are cool guys. This production was made possible by a number of reasons, among them the personal qualities, and (some no) gos.podderzhka and elementary luck. The main thing is that such plants in the country are rare and inconsistent. Any comparison with Western giants scale, innovation and turnover, they can not go.

Of course, I would like to «made in Russia" was a sign of quality, but yet somehow Yotafon and E-mobility are increasingly ... And for some reason it seems to me that the restraining technique, of course, will increase the turnover of those few plants that already it is working, but they do not create new ones. They will lower the technological equipment, take us to the Soviet economic model. Maybe I'm wrong and exaggerate, not seeing the long-term prospects. I would be glad if you convince me.

Source: shadrapa.livejournal.com

Instead, I'll show you how to actually produce in the Russian medical equipment. I was lucky enough to visit the factory in Kazan, where they make the systems and consumables for endoscopic surgery.

The name of the plant will not be called, that you may have not considered advertising the post or, conversely, to pounce, though, if you want to find it is not difficult, in Kazan only two such production, and even then - they were born out of the collapse of one.

After the overwhelming foreign vidosikov in mind the majority of consumers might get the idea of the coming twenty-first century and nanotechnology. On the scale of large companies and advertising - it is. But a small production, and even aggravated Russian realities, their calculations and planning. In short, who has ever tried to do something on their own perfectly understand what I mean.

The plant does everything for minimally invasive operations: tools, racks, camera, insufflator and still full of all. The director, it seemed to me a very sincere man, honest talks, saying that it is a copy of the German Storz, but the German is worse, but better than the Chinese, but it is cheaper but, as such a thing is not unique at all ...

That's warehouse. So, one of the shelves. What do you expect to see? A huge hangar with lift trucks? This is not a product that is shipped as a range of M-Video.

This is considered a huge amount. Each piece of hardware - the future endoscopic tool that domestic hospital will buy in the amount of one or two, high prices at tenders, for years to come.

For young people there machines. Cadres no man forges, and those that have - came with the collapse of the plants, even the old school masters.

Is there engineers, quality control technicians, that's all, but it was not a promotional tour blog, because you bore the "mandatory program" photo report is not going to.

According to those who have the equipment I use - it is good, really good tools do. Particularly pleased with customer-oriented, that is suitable for sterilizing equipment archaic systems that are installed in our hospitals, what can be done reusable - is, in contrast to foreign companies, where all one-time maximum.

But I'm not about to say what they are cool guys. This production was made possible by a number of reasons, among them the personal qualities, and (some no) gos.podderzhka and elementary luck. The main thing is that such plants in the country are rare and inconsistent. Any comparison with Western giants scale, innovation and turnover, they can not go.

Of course, I would like to «made in Russia" was a sign of quality, but yet somehow Yotafon and E-mobility are increasingly ... And for some reason it seems to me that the restraining technique, of course, will increase the turnover of those few plants that already it is working, but they do not create new ones. They will lower the technological equipment, take us to the Soviet economic model. Maybe I'm wrong and exaggerate, not seeing the long-term prospects. I would be glad if you convince me.

Source: shadrapa.livejournal.com