966

Lebedinsky Mining and Processing Plant

31 photos

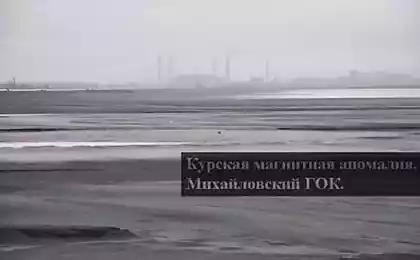

Kursk magnetic anomaly - the most powerful in the world iron ore basin. Currently, the border stretch of iron ore deposits KMA covers an area of over 160 thousand sq. Km, capturing the territory of the nine areas of the Center and South of the country. The largest enterprise of the Kursk Magnetic Anamaliya - "Lebedinsky Mining and Processing Plant" (Lebedinsky GOK), which is in the Belgorod region. Under the cut, also discussed the fate of the quarry.

Lebedinsky GOK is part of the holding "Metalloinvest" and is Russia's largest mining and processing of iron ore and the production of high quality raw materials for the steel industry.

The raw material base of the plant - unique in scale and quality of the reserves of ferruginous quartzites.

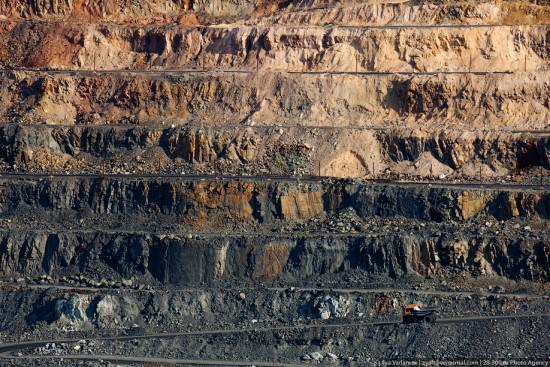

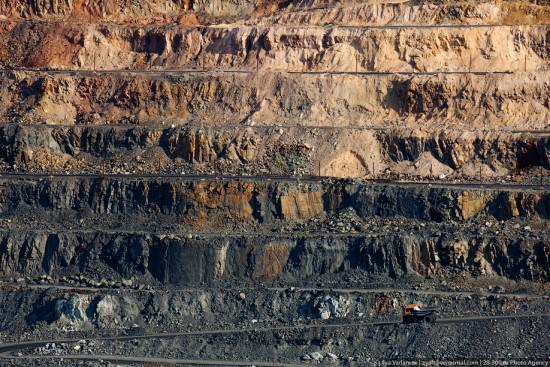

The initial link in the technological chain of production of iron ore is the quarry. Extraction of ore by open way by means of blasting, excavation and transportation of mined rock by road and rail.

Along the way, non-metallic mineral raw materials - sand, chalk, crystalline schists, quartzitic sandstone are mined by an internal railway transport is shipped to consumers.

Also, using rail transport is made unnecessary transportation of rock and loose rock to the special blades, which were later covered with earth and planted sea buckthorn.

Testing of the rock mass (removal of her career) precedes the explosive training carried out with the aim of loosening of the rock mass. Drilling of blast holes is performed by special drilling rigs. The wells are filled with charge and explode the chain. For 1-2 seconds in turn explodes several dozen wells. If you blow up all at the same time, the force of the detonation would be comparable to an earthquake.

Dobavleno1 in [mergetime] 1254568589 [/ mergetime]

Testing of ferruginous quartzite and rock made huge excavators of the "shovel". Bucket capacity of the excavator is 10 cubic meters, or the body of one of KAMAZ.

Operating weight of such machines about 400 tons, and height (with boom box head) almost five-story building. The crawler chassis allows you to move on slopes up to 12 degrees.

If working off passes near the railroad tracks, excavators are charged ore and parodies directly into cars.

In the case before the railway far, the ore is first loaded into dump trucks and then transferred to a rail on special transfer points in his career.

In addition, the loose overburden (at the loosened blast rock mass) used excavators of the "dragline" or the common people - "draglines." Unlike the caterpillar, the use of hydraulic walking mover reduces the load on the ground, so that the weight of the machine can reach hundreds and even thousands of tons. The greatest radius of the excavator digging up of almost 100 meters, which is five times more than the excavators "mechanical shovel."

Transportation of ore to the processing plant and the loose rock overburden dumps is made on special trains. At the head of the composition is OPE1 traction units, which is specially designed to work on the railways and open cast mining is able to pull out of a career laden Railroad dump cars (freight cars for transportation and automated unloading of the overburden). The mill trains are called "decks" for tipping for unloading the car body.

Because of the gradual development of career railways often have to be dismantled and re-transfer. Since the "pinwheel" run on electricity have to electrify all the way.

Of course, he relsoukladchik runs on diesel fuel.

Right in the quarry located facility for crushing of gravel for roads and railways career (top right).

In the year of the career of Lebedinsky GOK is exported to 50 million cubic meters of rock mass that allows the team to the plant to produce about a third of Russia's total iron ore products.

According to the forecasts in Lebedinsky iron ore reserves of the field amount to 11 billion tons, which ensures a stable supply of raw materials the company more than a hundred years.

19

20

21

Lebedinsky GOK is listed twice in the Guinness Book of Records:

As a company, develops unique reserves of iron ore deposit (20, 2 billion tons).

And, as a company, which has the world's largest quarry of non-combustible mineral resources.

The size of a giant "bowl" - a width of about four kilometers long and about five.

In the center of the quarry there is an island rock, similar in shape to the language. This waste rock and not to waste time on its exports to the Soviet era this place get round. Now mount a serious obstacle to further development and its krarera systematically began to develop.

The length of the railway lines at the plant is about 350 kilometers (approximately half the distance from Moscow to Belgorod).

Drilling rigs, excavators, huge dump trucks, bulldozers, trains, at a depth of 450 meters seem toy.

Dobavleno1 in [mergetime] 1254568952 [/ mergetime]

28

28

Systems drainage career includes dewatering wells, submersible pumps, drainage ditches and drainage vnutrikarernye device. All this is not visible from the outside, but the system is one of the most important at the plant. If you turn off the drainage system, the entire quarry filled with water for 3 days!

30

"Billionth cubic meters of rock mass. September 1993 »

Source

Source:

Kursk magnetic anomaly - the most powerful in the world iron ore basin. Currently, the border stretch of iron ore deposits KMA covers an area of over 160 thousand sq. Km, capturing the territory of the nine areas of the Center and South of the country. The largest enterprise of the Kursk Magnetic Anamaliya - "Lebedinsky Mining and Processing Plant" (Lebedinsky GOK), which is in the Belgorod region. Under the cut, also discussed the fate of the quarry.

Lebedinsky GOK is part of the holding "Metalloinvest" and is Russia's largest mining and processing of iron ore and the production of high quality raw materials for the steel industry.

The raw material base of the plant - unique in scale and quality of the reserves of ferruginous quartzites.

The initial link in the technological chain of production of iron ore is the quarry. Extraction of ore by open way by means of blasting, excavation and transportation of mined rock by road and rail.

Along the way, non-metallic mineral raw materials - sand, chalk, crystalline schists, quartzitic sandstone are mined by an internal railway transport is shipped to consumers.

Also, using rail transport is made unnecessary transportation of rock and loose rock to the special blades, which were later covered with earth and planted sea buckthorn.

Testing of the rock mass (removal of her career) precedes the explosive training carried out with the aim of loosening of the rock mass. Drilling of blast holes is performed by special drilling rigs. The wells are filled with charge and explode the chain. For 1-2 seconds in turn explodes several dozen wells. If you blow up all at the same time, the force of the detonation would be comparable to an earthquake.

Dobavleno1 in [mergetime] 1254568589 [/ mergetime]

Testing of ferruginous quartzite and rock made huge excavators of the "shovel". Bucket capacity of the excavator is 10 cubic meters, or the body of one of KAMAZ.

Operating weight of such machines about 400 tons, and height (with boom box head) almost five-story building. The crawler chassis allows you to move on slopes up to 12 degrees.

If working off passes near the railroad tracks, excavators are charged ore and parodies directly into cars.

In the case before the railway far, the ore is first loaded into dump trucks and then transferred to a rail on special transfer points in his career.

In addition, the loose overburden (at the loosened blast rock mass) used excavators of the "dragline" or the common people - "draglines." Unlike the caterpillar, the use of hydraulic walking mover reduces the load on the ground, so that the weight of the machine can reach hundreds and even thousands of tons. The greatest radius of the excavator digging up of almost 100 meters, which is five times more than the excavators "mechanical shovel."

Transportation of ore to the processing plant and the loose rock overburden dumps is made on special trains. At the head of the composition is OPE1 traction units, which is specially designed to work on the railways and open cast mining is able to pull out of a career laden Railroad dump cars (freight cars for transportation and automated unloading of the overburden). The mill trains are called "decks" for tipping for unloading the car body.

Because of the gradual development of career railways often have to be dismantled and re-transfer. Since the "pinwheel" run on electricity have to electrify all the way.

Of course, he relsoukladchik runs on diesel fuel.

Right in the quarry located facility for crushing of gravel for roads and railways career (top right).

In the year of the career of Lebedinsky GOK is exported to 50 million cubic meters of rock mass that allows the team to the plant to produce about a third of Russia's total iron ore products.

According to the forecasts in Lebedinsky iron ore reserves of the field amount to 11 billion tons, which ensures a stable supply of raw materials the company more than a hundred years.

19

20

21

Lebedinsky GOK is listed twice in the Guinness Book of Records:

As a company, develops unique reserves of iron ore deposit (20, 2 billion tons).

And, as a company, which has the world's largest quarry of non-combustible mineral resources.

The size of a giant "bowl" - a width of about four kilometers long and about five.

In the center of the quarry there is an island rock, similar in shape to the language. This waste rock and not to waste time on its exports to the Soviet era this place get round. Now mount a serious obstacle to further development and its krarera systematically began to develop.

The length of the railway lines at the plant is about 350 kilometers (approximately half the distance from Moscow to Belgorod).

Drilling rigs, excavators, huge dump trucks, bulldozers, trains, at a depth of 450 meters seem toy.

Dobavleno1 in [mergetime] 1254568952 [/ mergetime]

28

28

Systems drainage career includes dewatering wells, submersible pumps, drainage ditches and drainage vnutrikarernye device. All this is not visible from the outside, but the system is one of the most important at the plant. If you turn off the drainage system, the entire quarry filled with water for 3 days!

30

"Billionth cubic meters of rock mass. September 1993 »

Source

Source: