743

Samara "Baltika" - how it's done

Samara fotoblogger Vladimir Sverkalov unable to visit brewery "Baltika - Samara", which works on the ground in Samara since 2003 and has provided an interesting photo-

33 photos

The author writes: "I remember that year, as a student, liked to drink Samara, the last 5 years is not exactly drank a glass, but other brands of beer drink exactly. For me it was great news that the factory in Samara made "Baltika", "Arsenalnoye", "Neva", "Yarpivo", "Tuborg", Carlsberg, Asahi, Kronenbourg 1664. »

2. Patio of the checkpoint. First of all I want to say that the plant employs true professionals, very pleasant to me to communicate with people, not just like in Samara, sense of corporate culture.

3. Left malting plant, the right bottling and finished goods warehouse. On the right a bit to capture some of the gallery, which connects all the sections of the plant.

4. It all starts with an elevator in which the stored grain that is brought by rail. By the way, the second owner of Baltika in the number of cars after the Railways.

5. I thought the crowd of men with shovels slung grain in the barrel, where the beer is brewed, but it turns out it automatically goes to the crusher, then cleaned and then falls into the mashing with water, filtered by this field and only then enters the digesters.

6. In the brewhouse is very hot and sterile clean! In total there are 3 cooking procedure, ie It can simultaneously cooked to 3 beers. As already mentioned above, the ground falls into a vat of malt for mashing, ie mixing with the water from there into the vat for filtering, then the boiler will all boil, then into a vat to cool and final filtration.

7. In the window you can see how the beer is brewed!

8. Control brewhouse, only a few people on the monitor should be the whole process, so the shop is not crowded.

9. fermentation room. Brewed beer falls into the huge "tanks", where it will ferment for 14 days. It really amazes imagination design that seemed to hang in the air. The picture is hard to see, but in fact the "tanks" are covered with ice, it is necessary to maintain the required temperature for fermentation.

10. Below them are the compressors. At this point, we are very actively began to discuss the sensitive issue about preserving differences "live beer" and pasteurized. As a result, I learned, no preservatives are added to the beer, and not so-called "living beer" or draft does not differ from the bottle and cans. All the beer from a barrel and even taste exactly the same. And it is not only in the Baltic Sea are all white and fluffy, and all normal plants, including the Zhigulevskaya. Ie no preservatives, and tap "nerazlivnoe" taste is no different. If someone will insist that he feels the difference, even more so, and thinks no one will not argue, but the fact remains, I have seen

11. Then go to the line of bottling. Start with cleaning department and reject bottles hanging on the support table of possible defects.

12. Bottles lean close to bottling run, unfortunately, take a picture of the process of filling it is not possible.

13. The filled and corked bottles enter the machine for labeling.

14. The river flows from a bottle rejection (applies properly glued labels) and per package in the package.

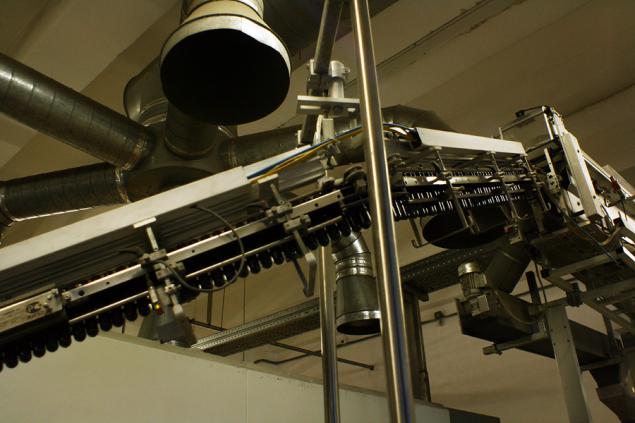

15. The conveyor is continuously covered with grease, if push bottle on an empty canvas, she can travel vertically 20 meters, I think so.

16. Then begins, something absolutely unreal!

In fact, I did not think that production in Samara there are so automated. So the package with bottles formed in the pallet, the pallet film wrap oneself in a vast machine, then it is glued label with a bar code.

17. finished pallet truck pulls up, the driver scans the barcode through the windshield, he gets on the computer and the route is rapidly disappearing. Everything happens with tact, probably in a minute. Forklifts drive at high speed along the narrow corridor between the pallets, that's where to look for Russian "Schumacher".

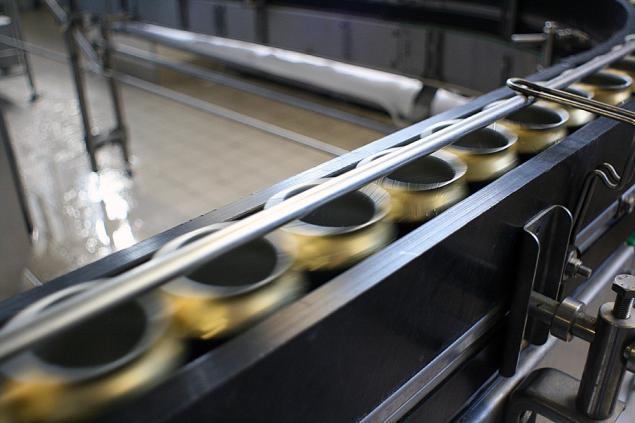

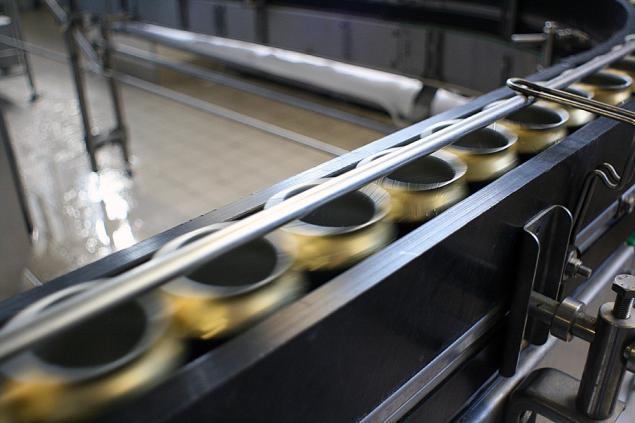

18. Warehouse of bottling divides into two parts, moving in the bottling of cans and plastic bottles.

19. Carefully look at the sides, like in Star Wars whistling here and there, carried by small cars.

20. Empty cans in large pallets arrive at the warehouse.

21. Next comes the hand culling.

22. Banks are moving with great speed, the focus is very difficult to catch.

23. Banks are still open.

24. As it turned out, I missed the aggregate bottling jars.

25. Then the banks get into the car for a very long pasteurization, moving on the conveyor inside the jars cool.

26. Inside the jars with hot water heated to 74 degrees.

27. Packages with banks to raise packing pallets.

28. A slightly different machine, but the principle is similar to the packaging of glass bottles.

29. Germ-liter plastic bottles.

30. The huge plant for bottling.

31. The labeling.

32. In England, the beer is brewed in a similar way.

33. They're coming to the warehouse.

Source:

33 photos

The author writes: "I remember that year, as a student, liked to drink Samara, the last 5 years is not exactly drank a glass, but other brands of beer drink exactly. For me it was great news that the factory in Samara made "Baltika", "Arsenalnoye", "Neva", "Yarpivo", "Tuborg", Carlsberg, Asahi, Kronenbourg 1664. »

2. Patio of the checkpoint. First of all I want to say that the plant employs true professionals, very pleasant to me to communicate with people, not just like in Samara, sense of corporate culture.

3. Left malting plant, the right bottling and finished goods warehouse. On the right a bit to capture some of the gallery, which connects all the sections of the plant.

4. It all starts with an elevator in which the stored grain that is brought by rail. By the way, the second owner of Baltika in the number of cars after the Railways.

5. I thought the crowd of men with shovels slung grain in the barrel, where the beer is brewed, but it turns out it automatically goes to the crusher, then cleaned and then falls into the mashing with water, filtered by this field and only then enters the digesters.

6. In the brewhouse is very hot and sterile clean! In total there are 3 cooking procedure, ie It can simultaneously cooked to 3 beers. As already mentioned above, the ground falls into a vat of malt for mashing, ie mixing with the water from there into the vat for filtering, then the boiler will all boil, then into a vat to cool and final filtration.

7. In the window you can see how the beer is brewed!

8. Control brewhouse, only a few people on the monitor should be the whole process, so the shop is not crowded.

9. fermentation room. Brewed beer falls into the huge "tanks", where it will ferment for 14 days. It really amazes imagination design that seemed to hang in the air. The picture is hard to see, but in fact the "tanks" are covered with ice, it is necessary to maintain the required temperature for fermentation.

10. Below them are the compressors. At this point, we are very actively began to discuss the sensitive issue about preserving differences "live beer" and pasteurized. As a result, I learned, no preservatives are added to the beer, and not so-called "living beer" or draft does not differ from the bottle and cans. All the beer from a barrel and even taste exactly the same. And it is not only in the Baltic Sea are all white and fluffy, and all normal plants, including the Zhigulevskaya. Ie no preservatives, and tap "nerazlivnoe" taste is no different. If someone will insist that he feels the difference, even more so, and thinks no one will not argue, but the fact remains, I have seen

11. Then go to the line of bottling. Start with cleaning department and reject bottles hanging on the support table of possible defects.

12. Bottles lean close to bottling run, unfortunately, take a picture of the process of filling it is not possible.

13. The filled and corked bottles enter the machine for labeling.

14. The river flows from a bottle rejection (applies properly glued labels) and per package in the package.

15. The conveyor is continuously covered with grease, if push bottle on an empty canvas, she can travel vertically 20 meters, I think so.

16. Then begins, something absolutely unreal!

In fact, I did not think that production in Samara there are so automated. So the package with bottles formed in the pallet, the pallet film wrap oneself in a vast machine, then it is glued label with a bar code.

17. finished pallet truck pulls up, the driver scans the barcode through the windshield, he gets on the computer and the route is rapidly disappearing. Everything happens with tact, probably in a minute. Forklifts drive at high speed along the narrow corridor between the pallets, that's where to look for Russian "Schumacher".

18. Warehouse of bottling divides into two parts, moving in the bottling of cans and plastic bottles.

19. Carefully look at the sides, like in Star Wars whistling here and there, carried by small cars.

20. Empty cans in large pallets arrive at the warehouse.

21. Next comes the hand culling.

22. Banks are moving with great speed, the focus is very difficult to catch.

23. Banks are still open.

24. As it turned out, I missed the aggregate bottling jars.

25. Then the banks get into the car for a very long pasteurization, moving on the conveyor inside the jars cool.

26. Inside the jars with hot water heated to 74 degrees.

27. Packages with banks to raise packing pallets.

28. A slightly different machine, but the principle is similar to the packaging of glass bottles.

29. Germ-liter plastic bottles.

30. The huge plant for bottling.

31. The labeling.

32. In England, the beer is brewed in a similar way.

33. They're coming to the warehouse.

Source: