870

The second life of a glass bottle

Now the life of the back of the bottle begins either with station waste sorting (they choose different types of waste from mixed waste, or from pre-sorted - in the cities, where there are separate waste collection) or reception center which, despite everything, still continue to exist. After the bottle, we went to the reception desk.

24 photo.

The point is always lively - people constantly bring and pass the different recyclables. The contingent of the receiving point is constant - basically, it's a neat pensioners. Many inspector knows by sight and by name.

According to him, in the day, people sit on recycled 4600-4800 rubles (at this point not only to take glass bottles and plastic, waste paper, aluminum cans). In summer, the turnover increased - it is understandable, because the consumption increases and various foam and not a beverage.

As you can see, this item receives bottles of different varieties of beer, vodka and other alcoholic beverages.

Paragraph bottles are sorted by type and are preparing to transfer the production, where the bottles are reused.

One of the major buyers of glass at this point is "Baltika" - its representatives work directly with the item. "Baltika" - one of the largest players in the segment. This means that the company is a model for other smaller productions. But it means that in the company is responsible for quite a lot of waste.

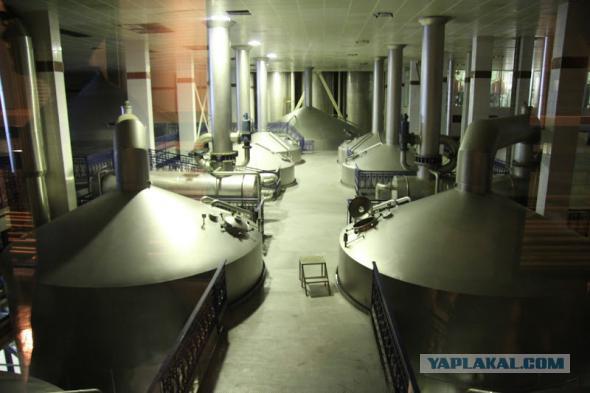

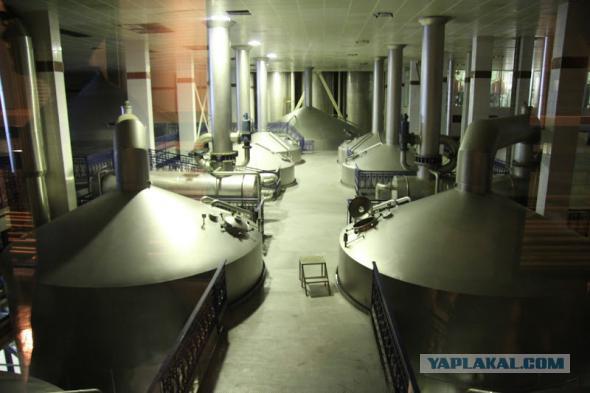

The headquarters and one of the company's plants located in St. Petersburg. On the plant and get the bottle from the receiving point at which we have already visited.

But before we see what is happening here already use bottles, we talked to the employees, who are also concerned about the ban on the back of the packaging. Stanislav Shitko, head of regional procurement, and is responsible for ensuring that "Baltika" secondary packaging.

Stanislav said that was extremely surprised and shocked by the adoption of technical regulations - "Baltika", like other breweries, just a fait accompli. There are no reasonable arguments, no explanation. At the same time, producers of juices, water and dairy products will continue to use the back a bottle - the ban only touched alcohol producers and baby food. The technical regulations there is a slight possibility that allows the preparation of a specific authorization to use the reverse bottle until 2014 - now the company is trying to achieve to obtain these permissions in order to continue to use recycled glass containers.

The company buys and uses in the production of bottle reverse since the beginning of the work (before 2003 generally use only a secondary glass containers!). Today "Baltika" work with 4500 points receiving recyclable materials throughout Russia - from Kaliningrad to Vladivostok. This allows the plants to return to production is about 50% of its bottles. And in the last few years, the percentage of using the back of the bottle has been gradually increasing.

Representatives of the "Baltic" refers to three reasons for their plant uses reverse bottle. The first reason - the economic feasibility. Recycled bottle costs about 20% cheaper than buying a new bottle. And reduced transportation costs, because the main glass production located in central Russia (in particular, in the Vladimir region), and plants scattered throughout the country. And in the case of secondary bottle plant buys container from local points.

The second reason - social responsibility. After use the back of the bottle - it is the most environmentally friendly way to reduce the amount of waste and not to waste natural resources, primary

And finally, the third reason - reducing risks. Recycled bottle has passed the test of time - you can be sure that it has no micro-cracks, it will not burst.

The main argument of the authors of the new technical regulations of the Customs Union was that already used one bottle may not be safe for the consumer. However, what is interesting: a new washing process and has already used the same bottle - both types of bottles held a series of cleaning and disinfecting in a special machine. Primary products from the bottle washed glass production, and the secondary - from the remnants of a drink, garbage and so on. However secondary bottle passes additional quality control step.

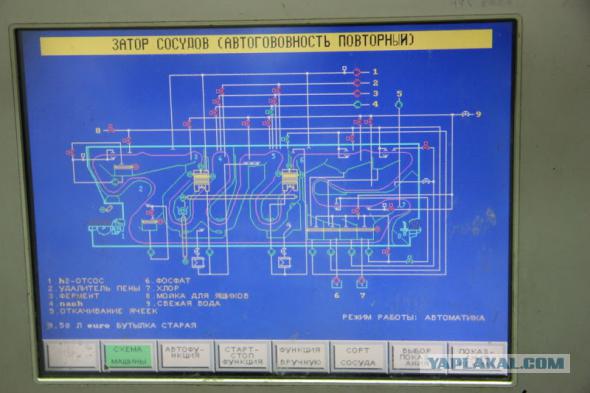

We leave in one of the shops of the company, which is equipped with modern German washer Krones - these machines are the most expensive and the most reliable.

More photos

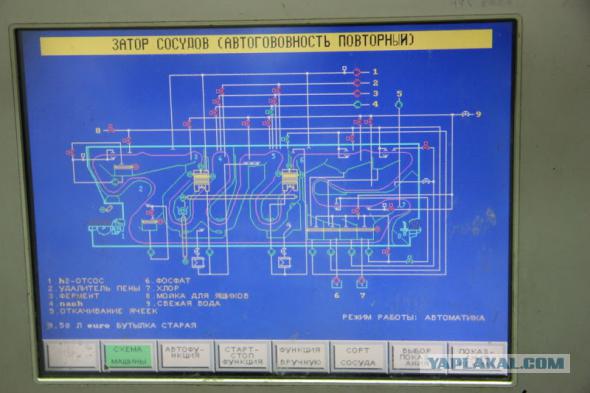

It takes a bottle of so-called road - car engines gradually move the bottle at different stages: preheating, alkaline baths, syringes, allowing wash bottle inside a bottle of lye laundering and gradual cooling. The combination of high temperatures and caustic soda gives the greatest disinfectant effect.

More photos

More

More photos

At the beginning of the bottles enter the cell, which then will be all the way in the car.

By the way, for a change here formed a cake labels, washed with bottles - they were not thrown out, and dried, pressed, and pass in the trash.

Performance of the machine is large enough - 60 thousand bottles per hour.

More photos

Each bottle holds in the car about 30-40 minutes - then the other side of the machine is already washed out and sparkling clean bottles. They go into the car inspector who monitors the quality of washed bottles. Inspector clean bottles discarded all the bottles that do not meet the necessary requirements.

The bottles in the car-inspector sweep and transmission at a furious pace, so take pictures of them - is not easy.

Bottles that have failed inspection, are returned to the line again and again tested the entire processing cycle in a washing machine - here try to send as little as possible cullet bottles. Bottles in this photo culled and sent back to bathing.

As a result of the washing machine and plant in which bottled beverages in about an hour bottle, widely regarded as the garbage is already filled and will be re-used. In the foreground - the bottles enter the washer, and the background is already finished product is sent to the consumer. Such is the cycle of bottles in a single plant.

Posted in [mergetime] 1391056741 [/ mergetime]

In conclusion, it should be noted that in the world there is a whole industry Bottle, which is represented by the various machines are commonly used in various factories. The industry is well developed and meets the necessary safety requirements.

Photos of George and Mary Timofeev Musatov.

Source:

24 photo.

The point is always lively - people constantly bring and pass the different recyclables. The contingent of the receiving point is constant - basically, it's a neat pensioners. Many inspector knows by sight and by name.

According to him, in the day, people sit on recycled 4600-4800 rubles (at this point not only to take glass bottles and plastic, waste paper, aluminum cans). In summer, the turnover increased - it is understandable, because the consumption increases and various foam and not a beverage.

As you can see, this item receives bottles of different varieties of beer, vodka and other alcoholic beverages.

Paragraph bottles are sorted by type and are preparing to transfer the production, where the bottles are reused.

One of the major buyers of glass at this point is "Baltika" - its representatives work directly with the item. "Baltika" - one of the largest players in the segment. This means that the company is a model for other smaller productions. But it means that in the company is responsible for quite a lot of waste.

The headquarters and one of the company's plants located in St. Petersburg. On the plant and get the bottle from the receiving point at which we have already visited.

But before we see what is happening here already use bottles, we talked to the employees, who are also concerned about the ban on the back of the packaging. Stanislav Shitko, head of regional procurement, and is responsible for ensuring that "Baltika" secondary packaging.

Stanislav said that was extremely surprised and shocked by the adoption of technical regulations - "Baltika", like other breweries, just a fait accompli. There are no reasonable arguments, no explanation. At the same time, producers of juices, water and dairy products will continue to use the back a bottle - the ban only touched alcohol producers and baby food. The technical regulations there is a slight possibility that allows the preparation of a specific authorization to use the reverse bottle until 2014 - now the company is trying to achieve to obtain these permissions in order to continue to use recycled glass containers.

The company buys and uses in the production of bottle reverse since the beginning of the work (before 2003 generally use only a secondary glass containers!). Today "Baltika" work with 4500 points receiving recyclable materials throughout Russia - from Kaliningrad to Vladivostok. This allows the plants to return to production is about 50% of its bottles. And in the last few years, the percentage of using the back of the bottle has been gradually increasing.

Representatives of the "Baltic" refers to three reasons for their plant uses reverse bottle. The first reason - the economic feasibility. Recycled bottle costs about 20% cheaper than buying a new bottle. And reduced transportation costs, because the main glass production located in central Russia (in particular, in the Vladimir region), and plants scattered throughout the country. And in the case of secondary bottle plant buys container from local points.

The second reason - social responsibility. After use the back of the bottle - it is the most environmentally friendly way to reduce the amount of waste and not to waste natural resources, primary

And finally, the third reason - reducing risks. Recycled bottle has passed the test of time - you can be sure that it has no micro-cracks, it will not burst.

The main argument of the authors of the new technical regulations of the Customs Union was that already used one bottle may not be safe for the consumer. However, what is interesting: a new washing process and has already used the same bottle - both types of bottles held a series of cleaning and disinfecting in a special machine. Primary products from the bottle washed glass production, and the secondary - from the remnants of a drink, garbage and so on. However secondary bottle passes additional quality control step.

We leave in one of the shops of the company, which is equipped with modern German washer Krones - these machines are the most expensive and the most reliable.

More photos

It takes a bottle of so-called road - car engines gradually move the bottle at different stages: preheating, alkaline baths, syringes, allowing wash bottle inside a bottle of lye laundering and gradual cooling. The combination of high temperatures and caustic soda gives the greatest disinfectant effect.

More photos

More

More photos

At the beginning of the bottles enter the cell, which then will be all the way in the car.

By the way, for a change here formed a cake labels, washed with bottles - they were not thrown out, and dried, pressed, and pass in the trash.

Performance of the machine is large enough - 60 thousand bottles per hour.

More photos

Each bottle holds in the car about 30-40 minutes - then the other side of the machine is already washed out and sparkling clean bottles. They go into the car inspector who monitors the quality of washed bottles. Inspector clean bottles discarded all the bottles that do not meet the necessary requirements.

The bottles in the car-inspector sweep and transmission at a furious pace, so take pictures of them - is not easy.

Bottles that have failed inspection, are returned to the line again and again tested the entire processing cycle in a washing machine - here try to send as little as possible cullet bottles. Bottles in this photo culled and sent back to bathing.

As a result of the washing machine and plant in which bottled beverages in about an hour bottle, widely regarded as the garbage is already filled and will be re-used. In the foreground - the bottles enter the washer, and the background is already finished product is sent to the consumer. Such is the cycle of bottles in a single plant.

Posted in [mergetime] 1391056741 [/ mergetime]

In conclusion, it should be noted that in the world there is a whole industry Bottle, which is represented by the various machines are commonly used in various factories. The industry is well developed and meets the necessary safety requirements.

Photos of George and Mary Timofeev Musatov.

Source: