996

Galosha as the engine of progress

Fashion for rubber footwear has long moved from Russia to Europe and back is not returned.

Protect shoes from moisture and cold feet, not forgetting about the convenience and elegance - not an easy task. To solve it required new technologies and bold ideas ...

From a functional point of view, overshoes can be defined as a third layer of shoes - socks bearing the first. But then you have to admit that they are in this class are not alone. There, at least, even bots that many in the kindergarten age brought a lot of trouble with pulling on top of the shoe, and then back to staskivaniem. Photo: Milos Luzanin / Shutterstock

Letters + 6 ph © Sergey Kutovojs

The Treasure of the Indians

"In vain, gentlemen, you go without galoshes!" - Said his uninvited guests hero famous literary works of Professor Preobrazhensky.

Today, his words may cause many a small smile, because in recent years galoshes reckon almost complete anachronism, along with boots from the distant happy childhood. But how wrong are those who think so! And paying the price for his mistake is unserviceable new shoes, then their health.

For centuries in Eurasia for the manufacture of footwear used three materials: leather, wood (including bark and) and cloth. Alas, all three have a common drawback - they are afraid of water, which inevitably occurs in the form of puddles gathered in precipitation, do not dry dirt country road or a fun babbling brook. Salo, or tar, so that the dignity of the place to discuss the characters of another literary work - "Evenings on a Farm near Dikanka" Gogol - not much alleviate the problem. Waterproof boots - the question of a successful combination of art and sound operation of a shoemaker.

A systematic wet feet easily transformed from home care in the state. After all, most people a serving his time in the open air, and therefore in need of good clothes and shoes. With the onset of cold rainy autumn in hospitals could easily be laid up half the army. Maybe that's why, and then chose to fight a hot summer or freezing winter?

But European civilization developed rapidly. We had to work hard and fight as much any time of year. And the aristocracy, coming out of their castles to the world, gasped in fear for the purity of their expensive clothes. Protection from the weather person at some point become a real geopolitical factor.

And in 1735, the French explorer Charles Marie de la Condamine (Charles-Marie de la Condamine, 1701-1774) went to explore the Amazon, where he met with the Hevea tree (Hevea brasiliensis) and latex, latex. From it evaporated sticky lumps of matter, called the Indians "Couch" (rubber), and the sages of the Paris Academy of Sciences fated rubber (from the Latin word resina, reisnae - ie resin gum). The natives have long used latex for impregnating fabrics, they shelter from the rain. It turned out that this fabric is not just fine withstand moisture - it ensures almost completely watertight.

Brought to Europe as overseas wonders, rubber is not immediately found a use. Decades before seen in him a real treasure Indians - perhaps far more valuable than all the gold of the legendary El Dorado. Because this new material was the raw material for countless rubber products: gaskets, hoses, tires and tubes, insulation materials and much, much more. None of which would hardly be possible, our technical civilization. However, the opening of the rubber, and the appearance of the rubber industry began with ... galoshes. More specifically, a solution of the urgent problem of wet feet.

The juice of rubber trees, also known as the rubber tree, kind of reminds dandelion juice and behaves during solidification is also very similar. Photos (Creative Commons license): Jon Rawlinson

Galoshes for Totosha

Natural latex impregnated fabric has a serious drawback, only partly familiar to Indians: heating up in the sun, this tissue becomes sticky, and in the cold - on the contrary, hardened like a stone, and even cracked. The latter was, perhaps, its main drawback. After all, the new material is appreciated overseas, primarily because of its flexibility, resistance to bending and other mechanical stress - nothing had traditional European water repellents.

Nevertheless, in 1791 the English hereditary shoemaker Samuel Peel (Samuel Peal, 1751-1818) patented his method of making cloth soaked in turpentine solution of rubber, which, however, did not save him from bankruptcy in 1793, but it has brought prosperity created by the company Peal & Co. It seems that around this time began the first experiments on the kind of protection shoe covers made of this fabric. But fame is not fully deserved, made a man to make her the first raincoat - Scotsman Charles Macintosh (Charles Macintosh, 1766-1843), which gave them produced Raincoat his name. He mixed rubber with various fillers (carbon black, oils, sulfur), trying to change its physical properties. His experiments were quite futile, but had a great importance for the future, because in the throes of being born a recipe for future rubber.

It came to light only in 1839, when an American researcher Charles Goodyear (Charles Goodyear, 1800-1860), accidentally forgotten on the stove a piece of cloth makintoshovskoy, discovered a method of curing - a chemical process in which the sulfur atoms connect the molecular chains of the rubber, turning it in a flexible and resistant material. And in the world to start a real boom in the rubberized fabric and rubber shoes. And at first the most important North American manufacturer of galoshes were the United States - they have exported to different countries of the world, including in Russia. They cost is not cheap, and buy them first could only rich people.

Today it may seem strange, but it is the "Lord" needed galoshes, like no other. It was not so much that their expensive shoes and boots had to be protected from getting wet, but in the fact that they did not want to go in dirty shoes in their offices and at home, dirtying flooring and carpets. "And my carpets are Persian!" - Philip Philipovich angrily explained the chairman of the House Committee Shvonder Transfiguration.

But pretty soon the mass production of galoshes made them accessible to all segments of the population. And this contributed to the technology of their production. Traditional leather or "canvas" shoes then produced mainly artisans single. Even the massive military orders did everything the same cobblers gathered in the dim halls of manufactories. All they needed to do - simple tool, pad and shoe anvil. So such a "small business", literally at his home, he could take any person with skillful hands, trained by a skilled shoemaker. The production of rubber galoshes was only possible at the factory, where there were serious equipment: machines for the manufacture of the rubber compound, rolling it into sheets calenders, vulcanizing autoclaves, mold and so on. D. Not to mention the accessories, which produces steam and drives a movement of these mechanisms. Working with such devices require special training, let alone guide it - in general and technical education.

In 1859, he arrived in St. Petersburg German businessman Ferdinand Krauzkopf (Ferdinand von Krauskopf), which is at home represented the interests of the US "galoshnoy" companies start production in Hamburg. Seeing the huge emerging market, Herr Krauzkopf quickly found investors, and a year later founded the "Association of the Russian-American factory", which built the first Russian factory for the production of galoshes, which received later the name "Triangle". The famous company that has been a half-century is the flagship of the domestic production of rubber footwear and rubber products.

On the complexity of the production is the fact that the first employees of the factory were foreign experts - and at the same time going training of the Russian workers and engineers. On respect for the valuable personnel said the fact the social arrangement of workers of the "triangle": due to the company were built apartment houses, a nursery and a school for their children, recreation, and even a bowling alley.

It would seem that long-held fashion galoshes suddenly back again. Perhaps it is a consequence of global climate change?

Impermeability - not only the dignity of rubber footwear. Galoshes served their owners for twenty years and more, while the tires did not begin to crack. Caring for them was very simple: it was enough to wash dirt galoshes, and they became as new again. And to give them a more elegant type of galoshes steel varnishing - covering the product with a thin layer of a special composition based on rubber. Then, in the XIX century, experiments were carried out to produce another galoshes, not just black color - with the result that there was a colored rubber, which later became the material for the production of toys, sporting goods and travel.

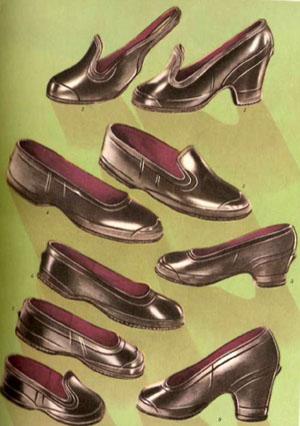

Popularity galoshes grew by leaps and bounds, and if the rich were still a means of protection against water, for the common people, they have become a major element in the then fashion. Primarily in galoshes shod then a continued part of winter costume as boots. Absolute impermeability rubber shoes made her extremely popular among those who had to work in conditions of constant dampness: farmers, fishermen, miners, who wore practical rubber boots.

But overshoes worn not only in wet weather. Light cotton or felt boots white with black galoshes became popular autumn footwear workers, clerks and merchants. And the shoes-off parade. To her wore new pants, a silk or satin shirt, trousers, vest, or "pindzhak" greased hair oil - and as such the then dudes went to visit for the holidays, at the reception to the authorities.

However, there appeared and disadvantages of rubber shoes: not only do not absorb moisture, but did not release it. Since they are not removed from the morning until the evening, the whole pot remained inside, and she tires very well spent (or rather - output) heat. Especially dangerous it was for those who wore the shoes "barefoot" without footcloths or warm socks. That was the appearance of its bad reputation as a cause of the common cold and rheumatism. Perhaps that is why it was not accepted as army uniforms - although on rubber boots dreamed many soldiers of the First World in flooded trenches. But army rubber boots came later in the form of the bottom of the chemical protection suit. And yet, amid the destruction of war, its production dramatically collapse, giving place to the production of a needed tires, rubber parts for cars, protivogaznyh masks. Ordinary galoshes become scarce and they are no longer worth the rash left in front unattended ...

In the middle latitudes Russia never came winter children's shoes, which could compete with the boots. Photo: Ugorenkov Aleksandr / Shutterstock

From boots to smartphones

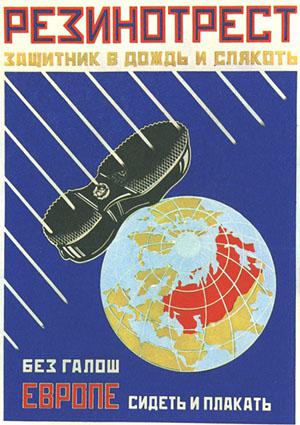

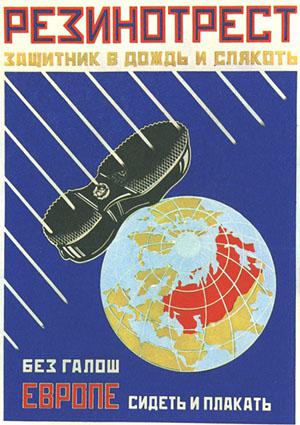

However, the devastation was not the main problem of the young Soviet rubber industry - already in the 20s release galoshes resumed. And in advertising products nationalized "Red Triangle" took part and the poet Vladimir Mayakovsky (1893-1930). But still acute was the shortage of imported natural rubber. Attempts to produce it from domestic plants (eg dandelion juice) or to no avail. And then it was decided to create its synthetic analogue. What in 1927 performed admirably chemist Sergey Lebedev (1847-1934), who in the absence of the necessary equipment in just a bottle of champagne has created the world's first synthetic butadiene rubber. This event was more than important, not only for the Soviet industry: synthetic rubbers have reduced consumption of natural and, more importantly, they have new properties - such as resistance to oils and gasoline.

It was not only a scarce overseas natural rubber, but also the domestic leather, which is not enough for mass production of military and work shoes. The problem was solved in the same way: in 1935, Ivan Vasilyevich Plotnikov (1902-1995) has developed a technology called "synthetic leather", all based on the same old recipe waterproof fabric. The cotton coat with calender special rubber mixture made embossed under the skin and vulcanized. This "leatherette" used for the manufacture of tops, and he is known to us under the name of "tarpaulin", which, according to legend, an abbreviation of "Kirov factory of artificial skin." Ugly and ridicule, he still differs cheapness and durability, and most importantly - was the first in a series of all kinds of "artificial skin", which are now widely used in the manufacture of footwear, outerwear, upholstery materials.

But perhaps the most important result of the use of rubber in the shoe industry was the production of soles. Before that they were made of leather, which had two drawbacks: she was suffering from the water and was completely smooth, so that winter shoes had to shoe, so it does not slip on the ice. And here at the sole galoshes already done with numerous small spines or serrated. The case remained for small: to launch the production of individual shoe soles. What's interesting: for a long time, not only the heel, but also the sole boots were separate parts that can be replaced. Only relatively recently, such a structure is gone, replaced by a full "one-off" shoe "monoblock».

It would seem that all these little things, unworthy of our attention. But let's imagine that the shoes are still made on the technology of our ancestors, from natural raw materials. The result would be not only our eternal wet feet, but the high cost of such a terrible shoes. We would hardly could buy a year a few pairs of new shoes and boots - so that the poor would have to walk like in the old days, in sandals or barefoot!

Meanwhile, rubber and polymers allow unthinkable cheap shoes in incredible numbers - and its typical example is the flip-flops, which, according to conservative estimates, today are more than two billion people living in Africa and Asia. With their apparent simplicity, for the production of these "sneakers" it was necessary to use a very complex and powerful equipment and technology of new materials. Pick up our room or beach sandals and a closer look at what was not noticed before: here and buckle made of artificial leather, and durable outer part of the sole of figure "protector" and a soft inner layer of sponge rubber. A minimum of three sophisticated manufacturing operations, which were then joined together by the fourth.

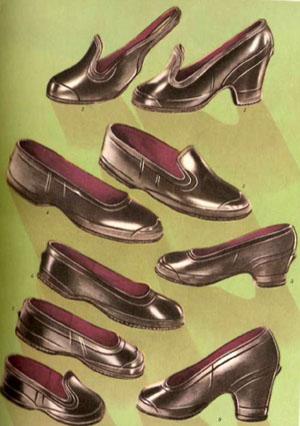

But back to our galoshes - that somehow have been unjustly forgotten. And - just us. Black galoshes with flannel inner trim red and black rubber boots (knee-length or higher "fishing") were the only domestic rubber footwear until the 50s. And then, the industry has decided to please the Soviet buyer more civilized range. Issue special galoshes for women's boots (under the heel), bright child and adolescent boots. The material, in addition to rubber, polyurethane, and polyvinyl chloride was used. Appeared in the city in the ordinary, "collective" rubber boots was in bad taste - they went only plumbers and builders.

As things like that in the Soviet Union, all dreamed about, to buy not just beautiful "civilized" rubber footwear, namely import. Including Finnish companies «Nokia» - that from 1923 to 1988, specializing, among other things, also on the issue of rubber products, including boots and galoshes. It is said that during the crisis they helped keep afloat the company, which now has worldwide fame thanks to their mobile phones.

The last boom in rubber boots have occurred in the late '80s, when there were very trendy boots combined: lower part of the cast from the "tractor" soles, uppers of rubber or nylon fabric and warm "wadded" insert. They can be worn with autumn until spring, not afraid of no water, no cold. And then ... she just disappeared. The stores were only hiking boots rather inconspicuous so ugly Chinese galoshes, not even rubber, and from some of the polymer, which put on his winter boots bazaar merchants.

Source:

Protect shoes from moisture and cold feet, not forgetting about the convenience and elegance - not an easy task. To solve it required new technologies and bold ideas ...

From a functional point of view, overshoes can be defined as a third layer of shoes - socks bearing the first. But then you have to admit that they are in this class are not alone. There, at least, even bots that many in the kindergarten age brought a lot of trouble with pulling on top of the shoe, and then back to staskivaniem. Photo: Milos Luzanin / Shutterstock

Letters + 6 ph © Sergey Kutovojs

The Treasure of the Indians

"In vain, gentlemen, you go without galoshes!" - Said his uninvited guests hero famous literary works of Professor Preobrazhensky.

Today, his words may cause many a small smile, because in recent years galoshes reckon almost complete anachronism, along with boots from the distant happy childhood. But how wrong are those who think so! And paying the price for his mistake is unserviceable new shoes, then their health.

For centuries in Eurasia for the manufacture of footwear used three materials: leather, wood (including bark and) and cloth. Alas, all three have a common drawback - they are afraid of water, which inevitably occurs in the form of puddles gathered in precipitation, do not dry dirt country road or a fun babbling brook. Salo, or tar, so that the dignity of the place to discuss the characters of another literary work - "Evenings on a Farm near Dikanka" Gogol - not much alleviate the problem. Waterproof boots - the question of a successful combination of art and sound operation of a shoemaker.

A systematic wet feet easily transformed from home care in the state. After all, most people a serving his time in the open air, and therefore in need of good clothes and shoes. With the onset of cold rainy autumn in hospitals could easily be laid up half the army. Maybe that's why, and then chose to fight a hot summer or freezing winter?

But European civilization developed rapidly. We had to work hard and fight as much any time of year. And the aristocracy, coming out of their castles to the world, gasped in fear for the purity of their expensive clothes. Protection from the weather person at some point become a real geopolitical factor.

And in 1735, the French explorer Charles Marie de la Condamine (Charles-Marie de la Condamine, 1701-1774) went to explore the Amazon, where he met with the Hevea tree (Hevea brasiliensis) and latex, latex. From it evaporated sticky lumps of matter, called the Indians "Couch" (rubber), and the sages of the Paris Academy of Sciences fated rubber (from the Latin word resina, reisnae - ie resin gum). The natives have long used latex for impregnating fabrics, they shelter from the rain. It turned out that this fabric is not just fine withstand moisture - it ensures almost completely watertight.

Brought to Europe as overseas wonders, rubber is not immediately found a use. Decades before seen in him a real treasure Indians - perhaps far more valuable than all the gold of the legendary El Dorado. Because this new material was the raw material for countless rubber products: gaskets, hoses, tires and tubes, insulation materials and much, much more. None of which would hardly be possible, our technical civilization. However, the opening of the rubber, and the appearance of the rubber industry began with ... galoshes. More specifically, a solution of the urgent problem of wet feet.

The juice of rubber trees, also known as the rubber tree, kind of reminds dandelion juice and behaves during solidification is also very similar. Photos (Creative Commons license): Jon Rawlinson

Galoshes for Totosha

Natural latex impregnated fabric has a serious drawback, only partly familiar to Indians: heating up in the sun, this tissue becomes sticky, and in the cold - on the contrary, hardened like a stone, and even cracked. The latter was, perhaps, its main drawback. After all, the new material is appreciated overseas, primarily because of its flexibility, resistance to bending and other mechanical stress - nothing had traditional European water repellents.

Nevertheless, in 1791 the English hereditary shoemaker Samuel Peel (Samuel Peal, 1751-1818) patented his method of making cloth soaked in turpentine solution of rubber, which, however, did not save him from bankruptcy in 1793, but it has brought prosperity created by the company Peal & Co. It seems that around this time began the first experiments on the kind of protection shoe covers made of this fabric. But fame is not fully deserved, made a man to make her the first raincoat - Scotsman Charles Macintosh (Charles Macintosh, 1766-1843), which gave them produced Raincoat his name. He mixed rubber with various fillers (carbon black, oils, sulfur), trying to change its physical properties. His experiments were quite futile, but had a great importance for the future, because in the throes of being born a recipe for future rubber.

It came to light only in 1839, when an American researcher Charles Goodyear (Charles Goodyear, 1800-1860), accidentally forgotten on the stove a piece of cloth makintoshovskoy, discovered a method of curing - a chemical process in which the sulfur atoms connect the molecular chains of the rubber, turning it in a flexible and resistant material. And in the world to start a real boom in the rubberized fabric and rubber shoes. And at first the most important North American manufacturer of galoshes were the United States - they have exported to different countries of the world, including in Russia. They cost is not cheap, and buy them first could only rich people.

Today it may seem strange, but it is the "Lord" needed galoshes, like no other. It was not so much that their expensive shoes and boots had to be protected from getting wet, but in the fact that they did not want to go in dirty shoes in their offices and at home, dirtying flooring and carpets. "And my carpets are Persian!" - Philip Philipovich angrily explained the chairman of the House Committee Shvonder Transfiguration.

But pretty soon the mass production of galoshes made them accessible to all segments of the population. And this contributed to the technology of their production. Traditional leather or "canvas" shoes then produced mainly artisans single. Even the massive military orders did everything the same cobblers gathered in the dim halls of manufactories. All they needed to do - simple tool, pad and shoe anvil. So such a "small business", literally at his home, he could take any person with skillful hands, trained by a skilled shoemaker. The production of rubber galoshes was only possible at the factory, where there were serious equipment: machines for the manufacture of the rubber compound, rolling it into sheets calenders, vulcanizing autoclaves, mold and so on. D. Not to mention the accessories, which produces steam and drives a movement of these mechanisms. Working with such devices require special training, let alone guide it - in general and technical education.

In 1859, he arrived in St. Petersburg German businessman Ferdinand Krauzkopf (Ferdinand von Krauskopf), which is at home represented the interests of the US "galoshnoy" companies start production in Hamburg. Seeing the huge emerging market, Herr Krauzkopf quickly found investors, and a year later founded the "Association of the Russian-American factory", which built the first Russian factory for the production of galoshes, which received later the name "Triangle". The famous company that has been a half-century is the flagship of the domestic production of rubber footwear and rubber products.

On the complexity of the production is the fact that the first employees of the factory were foreign experts - and at the same time going training of the Russian workers and engineers. On respect for the valuable personnel said the fact the social arrangement of workers of the "triangle": due to the company were built apartment houses, a nursery and a school for their children, recreation, and even a bowling alley.

It would seem that long-held fashion galoshes suddenly back again. Perhaps it is a consequence of global climate change?

Impermeability - not only the dignity of rubber footwear. Galoshes served their owners for twenty years and more, while the tires did not begin to crack. Caring for them was very simple: it was enough to wash dirt galoshes, and they became as new again. And to give them a more elegant type of galoshes steel varnishing - covering the product with a thin layer of a special composition based on rubber. Then, in the XIX century, experiments were carried out to produce another galoshes, not just black color - with the result that there was a colored rubber, which later became the material for the production of toys, sporting goods and travel.

Popularity galoshes grew by leaps and bounds, and if the rich were still a means of protection against water, for the common people, they have become a major element in the then fashion. Primarily in galoshes shod then a continued part of winter costume as boots. Absolute impermeability rubber shoes made her extremely popular among those who had to work in conditions of constant dampness: farmers, fishermen, miners, who wore practical rubber boots.

But overshoes worn not only in wet weather. Light cotton or felt boots white with black galoshes became popular autumn footwear workers, clerks and merchants. And the shoes-off parade. To her wore new pants, a silk or satin shirt, trousers, vest, or "pindzhak" greased hair oil - and as such the then dudes went to visit for the holidays, at the reception to the authorities.

However, there appeared and disadvantages of rubber shoes: not only do not absorb moisture, but did not release it. Since they are not removed from the morning until the evening, the whole pot remained inside, and she tires very well spent (or rather - output) heat. Especially dangerous it was for those who wore the shoes "barefoot" without footcloths or warm socks. That was the appearance of its bad reputation as a cause of the common cold and rheumatism. Perhaps that is why it was not accepted as army uniforms - although on rubber boots dreamed many soldiers of the First World in flooded trenches. But army rubber boots came later in the form of the bottom of the chemical protection suit. And yet, amid the destruction of war, its production dramatically collapse, giving place to the production of a needed tires, rubber parts for cars, protivogaznyh masks. Ordinary galoshes become scarce and they are no longer worth the rash left in front unattended ...

In the middle latitudes Russia never came winter children's shoes, which could compete with the boots. Photo: Ugorenkov Aleksandr / Shutterstock

From boots to smartphones

However, the devastation was not the main problem of the young Soviet rubber industry - already in the 20s release galoshes resumed. And in advertising products nationalized "Red Triangle" took part and the poet Vladimir Mayakovsky (1893-1930). But still acute was the shortage of imported natural rubber. Attempts to produce it from domestic plants (eg dandelion juice) or to no avail. And then it was decided to create its synthetic analogue. What in 1927 performed admirably chemist Sergey Lebedev (1847-1934), who in the absence of the necessary equipment in just a bottle of champagne has created the world's first synthetic butadiene rubber. This event was more than important, not only for the Soviet industry: synthetic rubbers have reduced consumption of natural and, more importantly, they have new properties - such as resistance to oils and gasoline.

It was not only a scarce overseas natural rubber, but also the domestic leather, which is not enough for mass production of military and work shoes. The problem was solved in the same way: in 1935, Ivan Vasilyevich Plotnikov (1902-1995) has developed a technology called "synthetic leather", all based on the same old recipe waterproof fabric. The cotton coat with calender special rubber mixture made embossed under the skin and vulcanized. This "leatherette" used for the manufacture of tops, and he is known to us under the name of "tarpaulin", which, according to legend, an abbreviation of "Kirov factory of artificial skin." Ugly and ridicule, he still differs cheapness and durability, and most importantly - was the first in a series of all kinds of "artificial skin", which are now widely used in the manufacture of footwear, outerwear, upholstery materials.

But perhaps the most important result of the use of rubber in the shoe industry was the production of soles. Before that they were made of leather, which had two drawbacks: she was suffering from the water and was completely smooth, so that winter shoes had to shoe, so it does not slip on the ice. And here at the sole galoshes already done with numerous small spines or serrated. The case remained for small: to launch the production of individual shoe soles. What's interesting: for a long time, not only the heel, but also the sole boots were separate parts that can be replaced. Only relatively recently, such a structure is gone, replaced by a full "one-off" shoe "monoblock».

It would seem that all these little things, unworthy of our attention. But let's imagine that the shoes are still made on the technology of our ancestors, from natural raw materials. The result would be not only our eternal wet feet, but the high cost of such a terrible shoes. We would hardly could buy a year a few pairs of new shoes and boots - so that the poor would have to walk like in the old days, in sandals or barefoot!

Meanwhile, rubber and polymers allow unthinkable cheap shoes in incredible numbers - and its typical example is the flip-flops, which, according to conservative estimates, today are more than two billion people living in Africa and Asia. With their apparent simplicity, for the production of these "sneakers" it was necessary to use a very complex and powerful equipment and technology of new materials. Pick up our room or beach sandals and a closer look at what was not noticed before: here and buckle made of artificial leather, and durable outer part of the sole of figure "protector" and a soft inner layer of sponge rubber. A minimum of three sophisticated manufacturing operations, which were then joined together by the fourth.

But back to our galoshes - that somehow have been unjustly forgotten. And - just us. Black galoshes with flannel inner trim red and black rubber boots (knee-length or higher "fishing") were the only domestic rubber footwear until the 50s. And then, the industry has decided to please the Soviet buyer more civilized range. Issue special galoshes for women's boots (under the heel), bright child and adolescent boots. The material, in addition to rubber, polyurethane, and polyvinyl chloride was used. Appeared in the city in the ordinary, "collective" rubber boots was in bad taste - they went only plumbers and builders.

As things like that in the Soviet Union, all dreamed about, to buy not just beautiful "civilized" rubber footwear, namely import. Including Finnish companies «Nokia» - that from 1923 to 1988, specializing, among other things, also on the issue of rubber products, including boots and galoshes. It is said that during the crisis they helped keep afloat the company, which now has worldwide fame thanks to their mobile phones.

The last boom in rubber boots have occurred in the late '80s, when there were very trendy boots combined: lower part of the cast from the "tractor" soles, uppers of rubber or nylon fabric and warm "wadded" insert. They can be worn with autumn until spring, not afraid of no water, no cold. And then ... she just disappeared. The stores were only hiking boots rather inconspicuous so ugly Chinese galoshes, not even rubber, and from some of the polymer, which put on his winter boots bazaar merchants.

Source: