696

How to make olive oil

Ilya Varlamov writes:

In Jordan, I visited the factory for the production of olive oil. To my surprise, the director of the plant started up production to shoot without question, conducted tours and was very pleased to visit. When I was shooting, the plant is not in full force, as the main crop is already processed. To plant in the offseason is not idle, the administration let the peasants here, which can recycle their crops. Anyone can bring their olives and making oil. The cost of 1 liter a total of 40 cents.

34 photos

01. The process of oil production begin with the collection of olives. Olives are collected only in a specific time when they are most ripe. In January, out of season, so the plant is working at the floor strength, low-quality raw materials are processed.

02. Olives are brought to the factory. It happens every day, which is very important as it reduces the daily transport between the collection and the process of spinning, which in turn improves the quality of the finished product.

03. The cost of olives are now about 60 cents per 1 kg.

04.

05.

06

07. Then the olives are washed.

08.

09

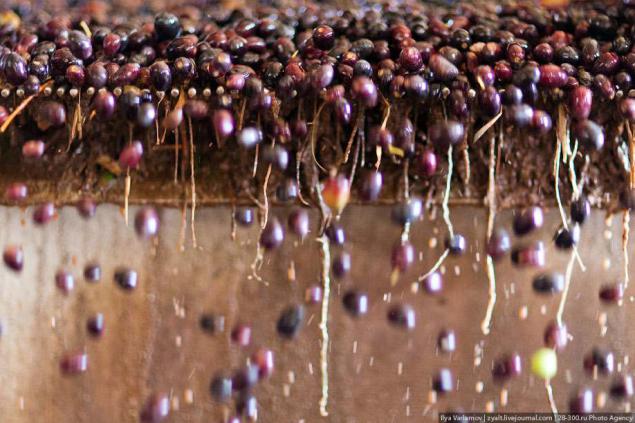

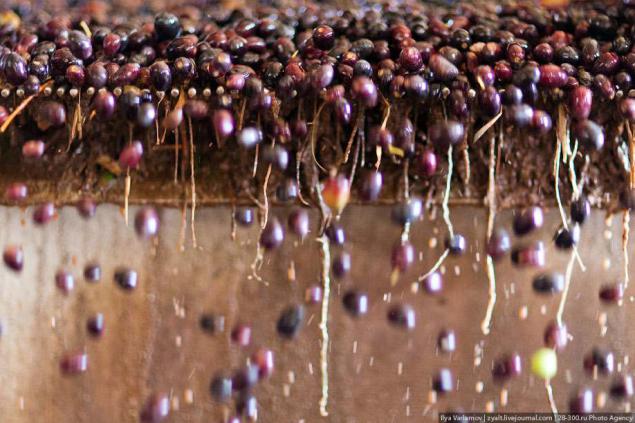

10. Immediately followed by the grinding process until a paste of olives. Generally, the olive oil is concentrated in the cells of the fetus. To extract it using a special device that resembles a mill consisting of two rolls rotating granite. This process allows the cells to extract the oil from the berries without heating, so the process is called "cold pressing".

11.

12

13

14. In a side part of the reservoir situated mill valve through which the pasta and exits is formed in the form of round pellets. Then they are placed on each other under a hydraulic press and subjected to further compression. The first result of pressure gives the oil of the highest quality, followed by a second and a third - the oil of lower quality. All these processes are hidden.

15

16

17

18. After pressing it turns out is such a liquid with water and olive slices.

19

20

21. The oil was then placed in a large settling tank for a period of 30-40 days. During this time, the olive oil became clear and ready for use. Color of oil depends on the variety and ripeness of the olives.

22

23. The final stage: the oil is poured into the separator to separate it from the water and fine particulate matter. To avoid the deterioration of oil quality during this process adheres temperature 16-28 ° C.

24. The finished oil is poured into canisters.

25

26. High-quality olive oil must be stored in dark glass bottles to prevent chemical processes. The acid content of olive oil oxidation causes plastic bottles. Long-term storage of olive oil in plastic bottles at the temperature difference can lead to a chemical process.

27. The best can be considered extra-virgin olive oil is not filtered, (write the English on the label. Extra Virgin Unfiltered Olive Oil, or extra-unfiltered (indicated on its label Italian. Olio d'oliva l'extravergine, Eng. Extra virgin olive oil, or App. extra virgin). This olive oil acidity is typically less than 1%, and it is believed that the lower the acidity of the oil, the higher its quality. Even more valuable is considered to be "drip" olive oil "cold pressed" (Engl. first cold press ), although this concept is rather arbitrary - oil in varying degrees, heated and "cold pressing».

28

29

30

31

32. Remains of olives and dried doing here such briketiki. They are used as fuel for furnaces.

33. Sometimes the taste and flavor in the oil add the garlic, peppers and other products. This is done by hand.

34

Source:

In Jordan, I visited the factory for the production of olive oil. To my surprise, the director of the plant started up production to shoot without question, conducted tours and was very pleased to visit. When I was shooting, the plant is not in full force, as the main crop is already processed. To plant in the offseason is not idle, the administration let the peasants here, which can recycle their crops. Anyone can bring their olives and making oil. The cost of 1 liter a total of 40 cents.

34 photos

01. The process of oil production begin with the collection of olives. Olives are collected only in a specific time when they are most ripe. In January, out of season, so the plant is working at the floor strength, low-quality raw materials are processed.

02. Olives are brought to the factory. It happens every day, which is very important as it reduces the daily transport between the collection and the process of spinning, which in turn improves the quality of the finished product.

03. The cost of olives are now about 60 cents per 1 kg.

04.

05.

06

07. Then the olives are washed.

08.

09

10. Immediately followed by the grinding process until a paste of olives. Generally, the olive oil is concentrated in the cells of the fetus. To extract it using a special device that resembles a mill consisting of two rolls rotating granite. This process allows the cells to extract the oil from the berries without heating, so the process is called "cold pressing".

11.

12

13

14. In a side part of the reservoir situated mill valve through which the pasta and exits is formed in the form of round pellets. Then they are placed on each other under a hydraulic press and subjected to further compression. The first result of pressure gives the oil of the highest quality, followed by a second and a third - the oil of lower quality. All these processes are hidden.

15

16

17

18. After pressing it turns out is such a liquid with water and olive slices.

19

20

21. The oil was then placed in a large settling tank for a period of 30-40 days. During this time, the olive oil became clear and ready for use. Color of oil depends on the variety and ripeness of the olives.

22

23. The final stage: the oil is poured into the separator to separate it from the water and fine particulate matter. To avoid the deterioration of oil quality during this process adheres temperature 16-28 ° C.

24. The finished oil is poured into canisters.

25

26. High-quality olive oil must be stored in dark glass bottles to prevent chemical processes. The acid content of olive oil oxidation causes plastic bottles. Long-term storage of olive oil in plastic bottles at the temperature difference can lead to a chemical process.

27. The best can be considered extra-virgin olive oil is not filtered, (write the English on the label. Extra Virgin Unfiltered Olive Oil, or extra-unfiltered (indicated on its label Italian. Olio d'oliva l'extravergine, Eng. Extra virgin olive oil, or App. extra virgin). This olive oil acidity is typically less than 1%, and it is believed that the lower the acidity of the oil, the higher its quality. Even more valuable is considered to be "drip" olive oil "cold pressed" (Engl. first cold press ), although this concept is rather arbitrary - oil in varying degrees, heated and "cold pressing».

28

29

30

31

32. Remains of olives and dried doing here such briketiki. They are used as fuel for furnaces.

33. Sometimes the taste and flavor in the oil add the garlic, peppers and other products. This is done by hand.

34

Source: