1085

Restoration of Sayano-Shushenskaya HPP

At the time of the accident, which occurred on 17 August 2009, in the hydraulic units were nine out of ten (№ 6 was in reserve). As a result, damage to the hydro unit number 2 spewed large amounts of water from the crater of the turbine, which destroyed part of the roof and damaged the structural columns of machine hall. As a result, any water got all the hydroelectric hydroelectric power and mechanical damage, and out of order.

Passed since the accident and a half years, during this time was the first stage of reconstruction of the station and put into operation four hydroelectric. Unlike last winter, pass the water through the dam is carried out in the normal mode through culverts paths hydraulic units working without idle discharges.

via chistoprudov

1. The engine room HPS initially was taken by 10 hydroelectric units with a capacity of 640 MW. The maximum water flow rate through the turbine is 358 cubic meters per second, the turbine efficiency in the optimum zone of about 96%.

2. The building of hydroelectric turbine hall is impressive - almost 300 meters long. On the right side you can see the panorama section of the roof, which was rebuilt after the accident.

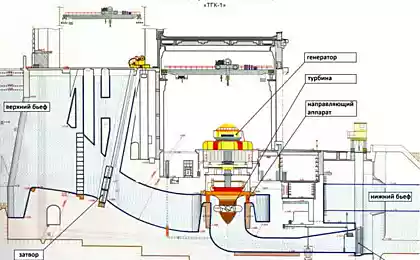

2a. The section of the dam and the turbine hall c hydraulic unit.

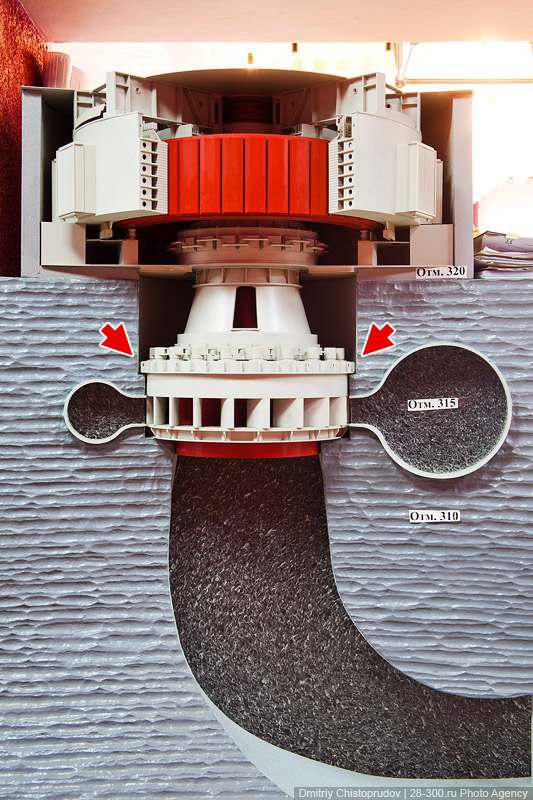

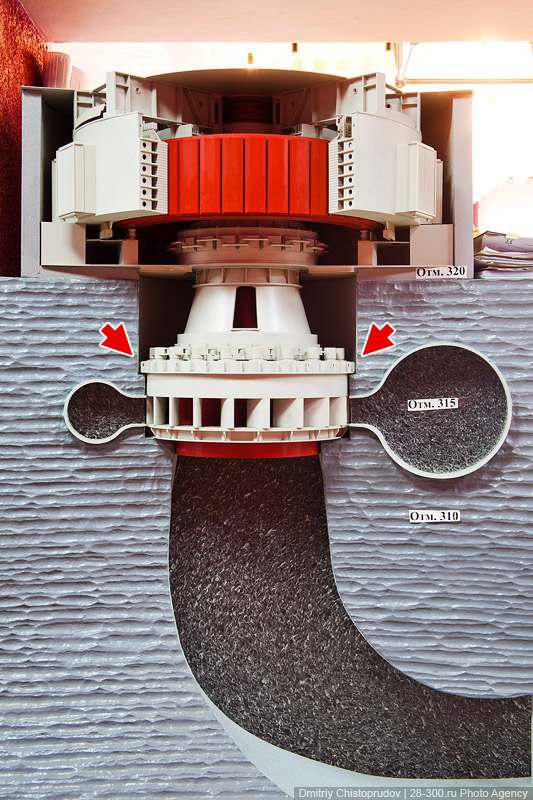

3. Cut the hydraulic unit. The investigation revealed that the immediate cause of the accident was a fatigue failure of the hydraulic unit cover mounting studs №2 (locations marked by the arrows), which led to its failure and flooding of the computer room.

4. Today, the station is actively working to restore the machine room. Here is the place of installation of hydraulic unit №2.

5. A comparison with what had been over a year ago. Author gelio_nsk.

Oleg Myakishev, an eyewitness of the accident, describes this moment as:

"... I was upstairs, heard a growing noise and then saw rises dybitsya corrugated covering hydroelectric. Then he saw from under him raised rotor. He rotated. His eyes did not believe it. He stood three meters. Threw stones, pieces of rebar, we began to turn aside from them ... Riflёnka was somewhere under the roof already, and the very roof blown ... I figured: rising water, 380 cubic meters per second, and - dёru in the direction of the tenth unit. I thought I did not have time, got up, stopped, looked down - look, collapsing all the water comes, people are trying to go ... I thought that the gates should be closed urgently by hand to stop the water ... by hand, because the voltage is not present, no protection did not work ... »

6. Another comparison.

7. Streams of water quickly flooded the engine room and the space under it. All the hydroelectric hydroelectric power station were flooded, while working on hydrogenerators shorted, who brought them out of action. There was a full load shedding hydropower plant, which led to the station blackout.

8. measures undertaken after the accident, a total station blackout rule. Additionally installed diesel generators that start automatically when the main power failure, with whatever it was due.

9.

10. Also added to the system of vibration control for thirty-nine sensors installed on each hydraulic unit that track movement of the shaft and the fluctuations of the assembly. The protection wakes up if the steady state operation of hydraulic unit for more than 15 seconds is kept elevated levels of maximum vibration.

11. "RusHydro" entered into a contract with OAO "Power Machines" for the supply of equipment to the hydropower plant. During 2011, the company will manufacture six new hydroelectric units.

12.

13. In the engine room there are two gantry cranes of 500 tons.

14. cranes can work in tandem to lift immediately and 1,000 tons.

15. For the analysis of more than 5,000 cubic meters of rubble, around 10 hydroelectric organized technological entry for trucks.

16. Since the entry was not initially provided, room for maneuver is practically no. We must really try to drive into the hall with a semi-trailer truck ...

17.

18.

19. Part of the process equipment is collected directly mounting the plant site, and some brought from St. Petersburg. For example impellers water turbines with a diameter of more than 6 meters, deliver water transport.

20.

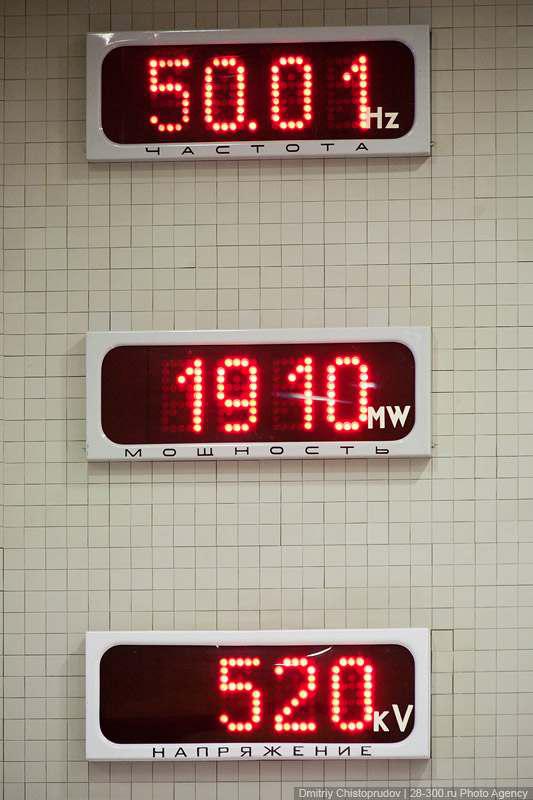

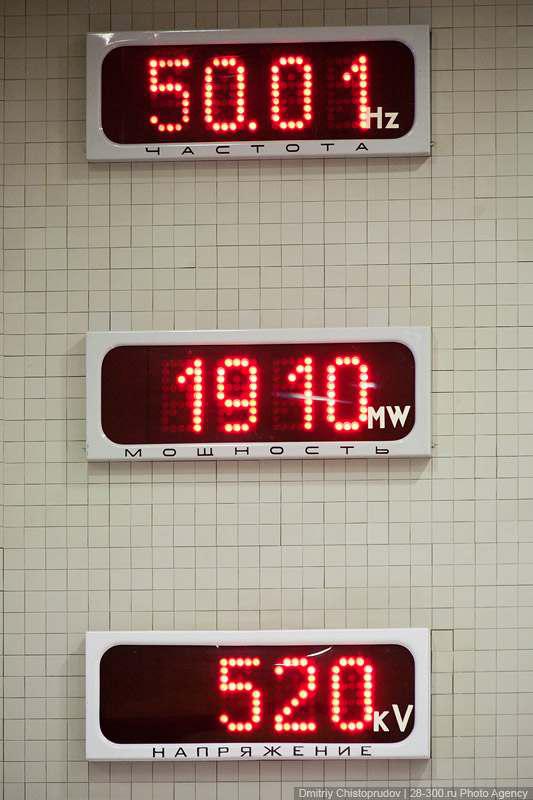

21. Who is the station's capacity is 2560 MW.

22.

23. Zone of working hydraulic units.

24.

25. The turbine is driven by synchronous hydro with a rotor diameter of 10 m 3, outstanding current voltage of 15, 75 kV. According to the results of tests capable of developing new hydroelectric power to 720 MW.

26. Technical facilities in the area of operating hydroelectric.

27. The cylindrical wall of the hydraulic unit and various equipment.

As a result of the accident, all these areas were flooded. 75 people were killed.

28.

29.

30.

31. Within the operating hydroelectric quite noisy ...

32. One of the technical galleries.

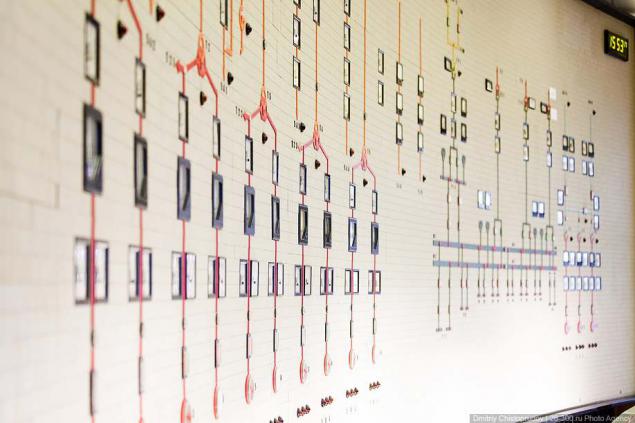

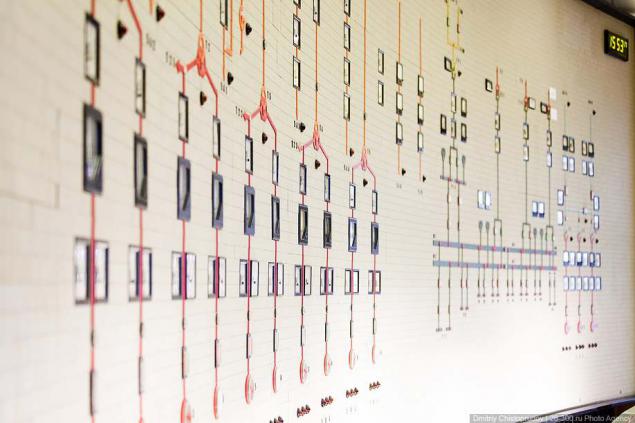

33. The central control power plant.

34.

35. Upgraded security system stops the machine when the power supply is lost, including at an extraordinary situation: the cable breaks, fire, flooding and closure. The action of protection leads to the closure of the guide apparatus, emergency repair gate and turn off the generator from the network.

36.

37. Even if for some reason the automatic does not work, stop the hydraulic unit and reset the emergency repair gates, you can use the special keys on the center console. Emergency keys existed before, but they were directly from the hydraulic units. During the accident, these marks were flooded, and use the key was not possible.

Source:

Passed since the accident and a half years, during this time was the first stage of reconstruction of the station and put into operation four hydroelectric. Unlike last winter, pass the water through the dam is carried out in the normal mode through culverts paths hydraulic units working without idle discharges.

via chistoprudov

1. The engine room HPS initially was taken by 10 hydroelectric units with a capacity of 640 MW. The maximum water flow rate through the turbine is 358 cubic meters per second, the turbine efficiency in the optimum zone of about 96%.

2. The building of hydroelectric turbine hall is impressive - almost 300 meters long. On the right side you can see the panorama section of the roof, which was rebuilt after the accident.

2a. The section of the dam and the turbine hall c hydraulic unit.

3. Cut the hydraulic unit. The investigation revealed that the immediate cause of the accident was a fatigue failure of the hydraulic unit cover mounting studs №2 (locations marked by the arrows), which led to its failure and flooding of the computer room.

4. Today, the station is actively working to restore the machine room. Here is the place of installation of hydraulic unit №2.

5. A comparison with what had been over a year ago. Author gelio_nsk.

Oleg Myakishev, an eyewitness of the accident, describes this moment as:

"... I was upstairs, heard a growing noise and then saw rises dybitsya corrugated covering hydroelectric. Then he saw from under him raised rotor. He rotated. His eyes did not believe it. He stood three meters. Threw stones, pieces of rebar, we began to turn aside from them ... Riflёnka was somewhere under the roof already, and the very roof blown ... I figured: rising water, 380 cubic meters per second, and - dёru in the direction of the tenth unit. I thought I did not have time, got up, stopped, looked down - look, collapsing all the water comes, people are trying to go ... I thought that the gates should be closed urgently by hand to stop the water ... by hand, because the voltage is not present, no protection did not work ... »

6. Another comparison.

7. Streams of water quickly flooded the engine room and the space under it. All the hydroelectric hydroelectric power station were flooded, while working on hydrogenerators shorted, who brought them out of action. There was a full load shedding hydropower plant, which led to the station blackout.

8. measures undertaken after the accident, a total station blackout rule. Additionally installed diesel generators that start automatically when the main power failure, with whatever it was due.

9.

10. Also added to the system of vibration control for thirty-nine sensors installed on each hydraulic unit that track movement of the shaft and the fluctuations of the assembly. The protection wakes up if the steady state operation of hydraulic unit for more than 15 seconds is kept elevated levels of maximum vibration.

11. "RusHydro" entered into a contract with OAO "Power Machines" for the supply of equipment to the hydropower plant. During 2011, the company will manufacture six new hydroelectric units.

12.

13. In the engine room there are two gantry cranes of 500 tons.

14. cranes can work in tandem to lift immediately and 1,000 tons.

15. For the analysis of more than 5,000 cubic meters of rubble, around 10 hydroelectric organized technological entry for trucks.

16. Since the entry was not initially provided, room for maneuver is practically no. We must really try to drive into the hall with a semi-trailer truck ...

17.

18.

19. Part of the process equipment is collected directly mounting the plant site, and some brought from St. Petersburg. For example impellers water turbines with a diameter of more than 6 meters, deliver water transport.

20.

21. Who is the station's capacity is 2560 MW.

22.

23. Zone of working hydraulic units.

24.

25. The turbine is driven by synchronous hydro with a rotor diameter of 10 m 3, outstanding current voltage of 15, 75 kV. According to the results of tests capable of developing new hydroelectric power to 720 MW.

26. Technical facilities in the area of operating hydroelectric.

27. The cylindrical wall of the hydraulic unit and various equipment.

As a result of the accident, all these areas were flooded. 75 people were killed.

28.

29.

30.

31. Within the operating hydroelectric quite noisy ...

32. One of the technical galleries.

33. The central control power plant.

34.

35. Upgraded security system stops the machine when the power supply is lost, including at an extraordinary situation: the cable breaks, fire, flooding and closure. The action of protection leads to the closure of the guide apparatus, emergency repair gate and turn off the generator from the network.

36.

37. Even if for some reason the automatic does not work, stop the hydraulic unit and reset the emergency repair gates, you can use the special keys on the center console. Emergency keys existed before, but they were directly from the hydraulic units. During the accident, these marks were flooded, and use the key was not possible.

Source: