918

Viluiskaya HPP

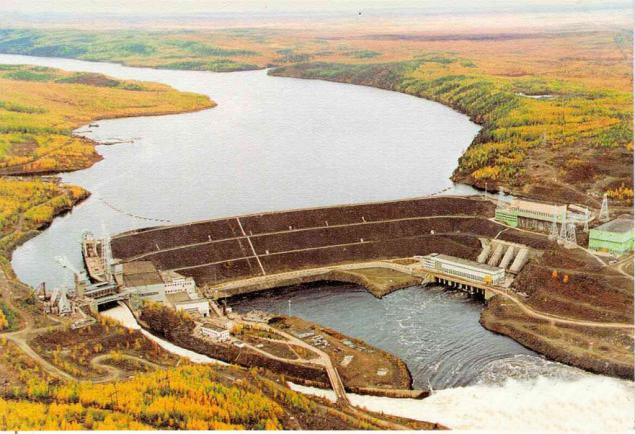

HPP construction began in 1960, ended in 1978. The power plant was built in the 2nd stage, called HPS-I and HPP-II.

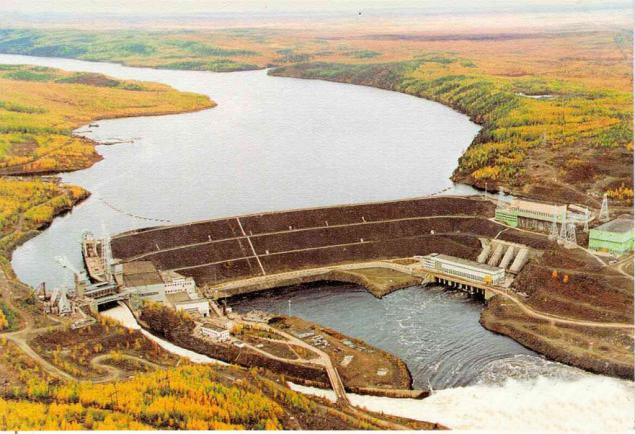

Composition hydroelectric facilities: dam 600 m long and 75 m maximum height

Power HPP - 680 MW,.

The building HPP-I has 4 Kaplan hydro capacity of 85 MW

The building HES-II has 4 Francis hydro capacity of 85 MW.

From the station, laid 5 220 kV transmission lines in the Lena through peaceful, and with a successful Aikhal.

Viluiskaya HPP gave the opportunity to start a large-scale development of diamond deposits in Yakutia. The main consumer of electricity is JSC "ALROSA". Cost of 1 kWh of electricity in 2013 - 90 kopecks.

Viluiskaya HPP was built in extremely difficult conditions of permafrost. Many designs were worked out for the first time.

29 photos will be

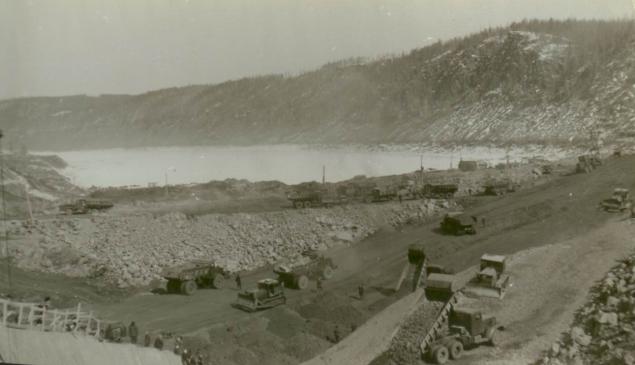

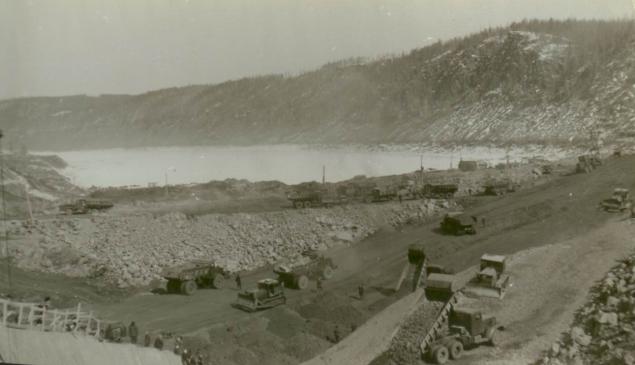

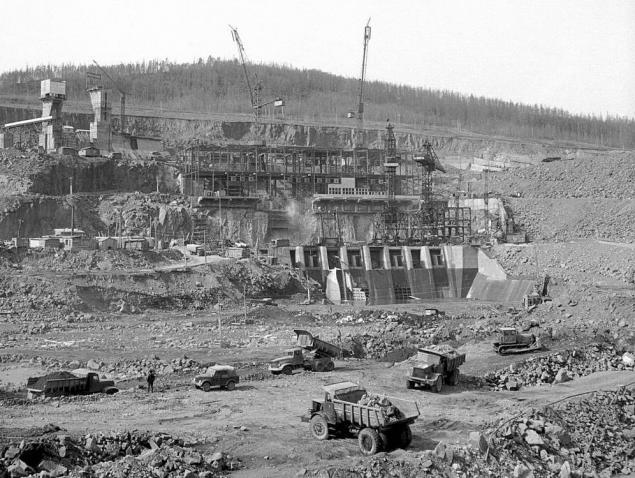

The beginning of construction in 1960

Laying the foundation of loam in the dam - everything happens at subzero temperatures

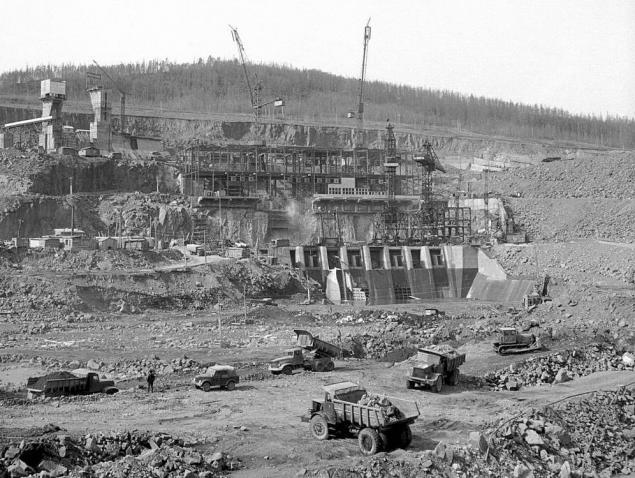

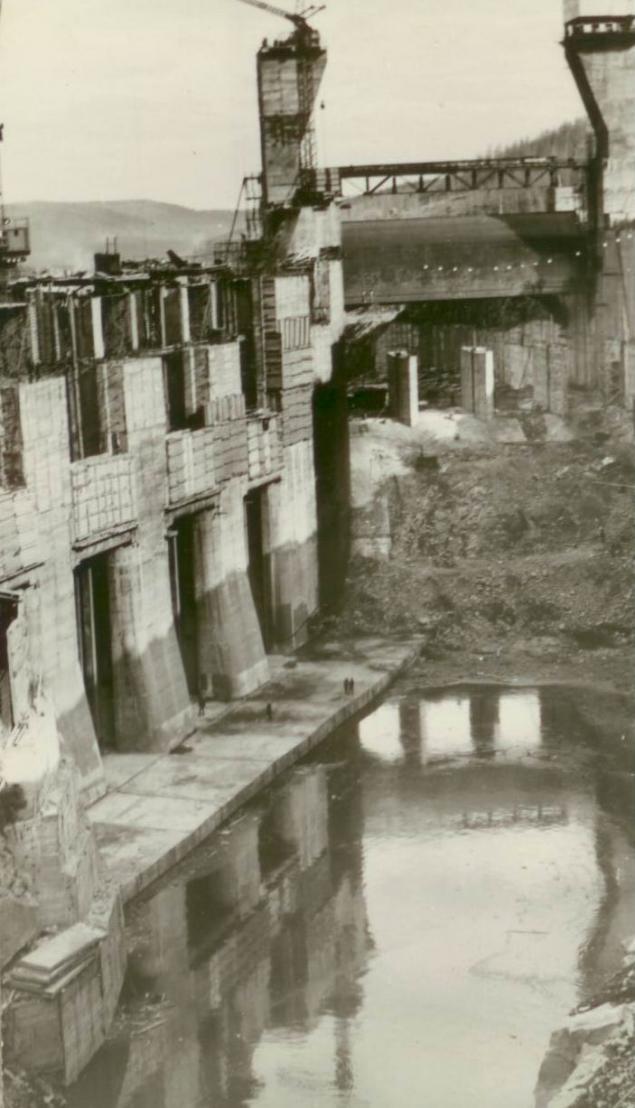

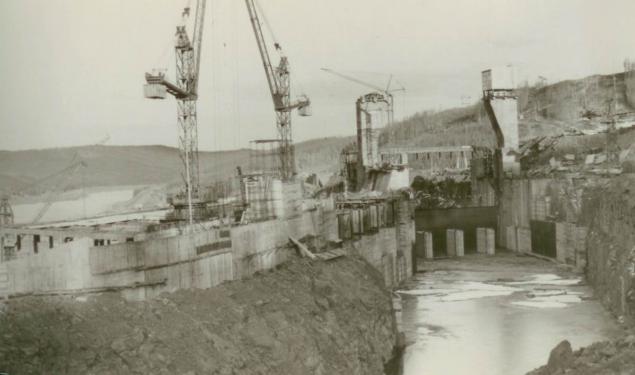

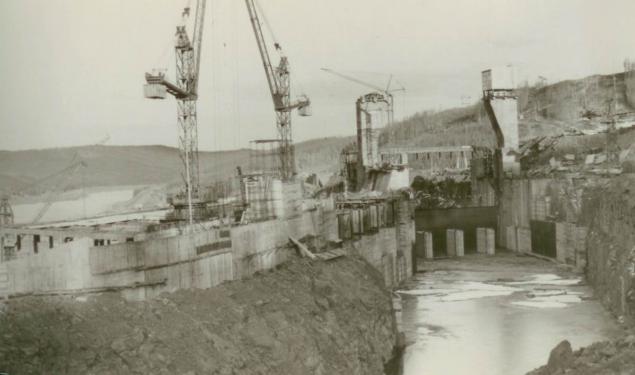

Construction of the first stage of HPP-1

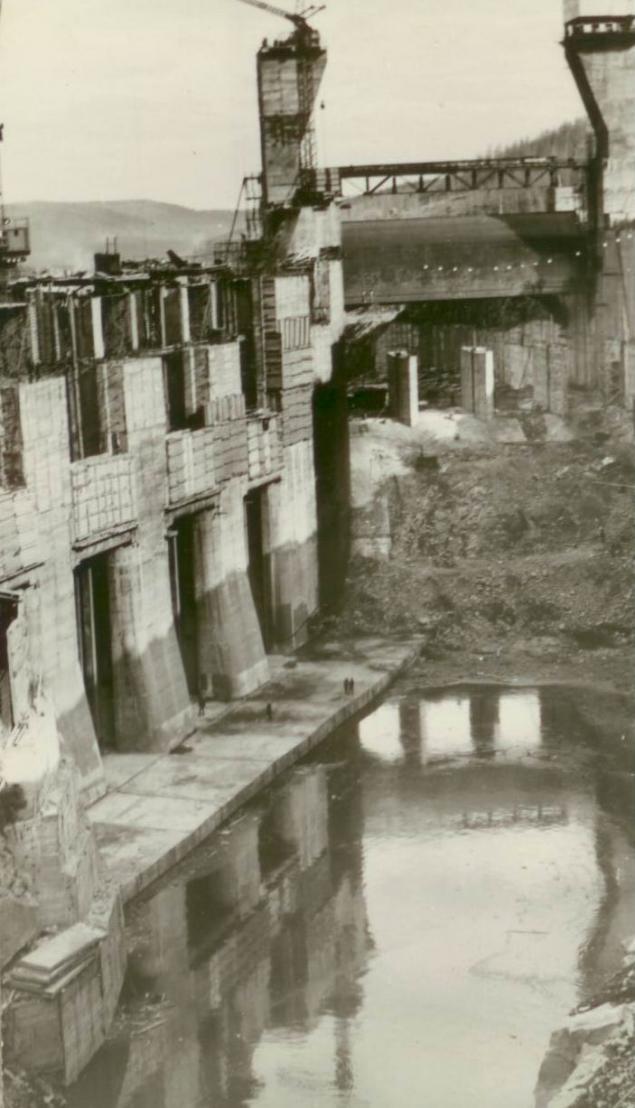

Again blow the dam - is seen as the ground is heated with a heat gun, and then ukatyvayut laden dump trucks. By stacking technology made in the winter and now round the dam has an internal temperature of minus 5, 5. In fact - the dam huge chunk of frozen clay

What used to be a beautiful girl!

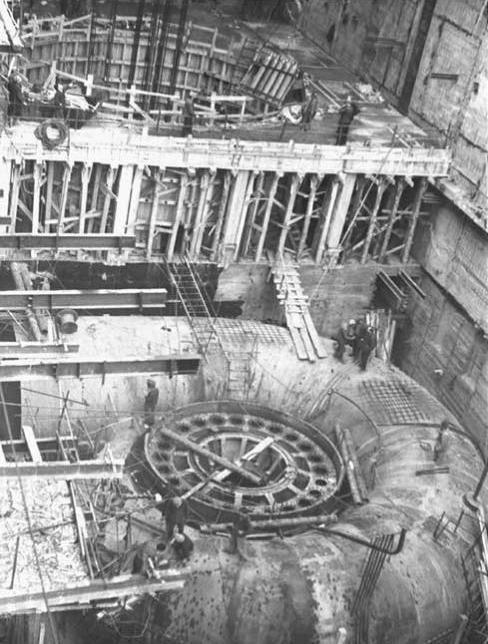

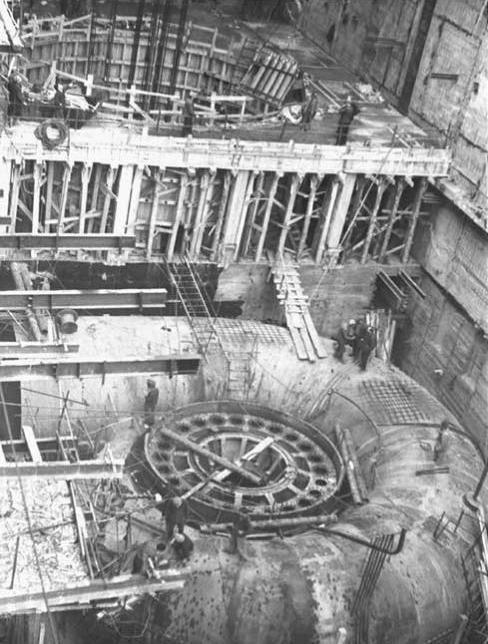

Volute hydroelectric

Pouring concrete using Zielke - there was no cement

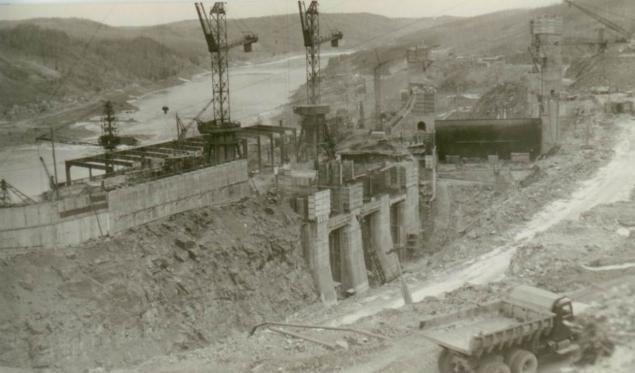

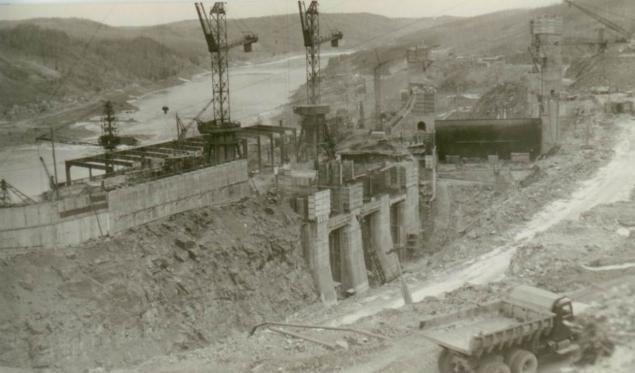

Start of construction of the receiving water

There soon will flood all

Flooding water intake HPP-1

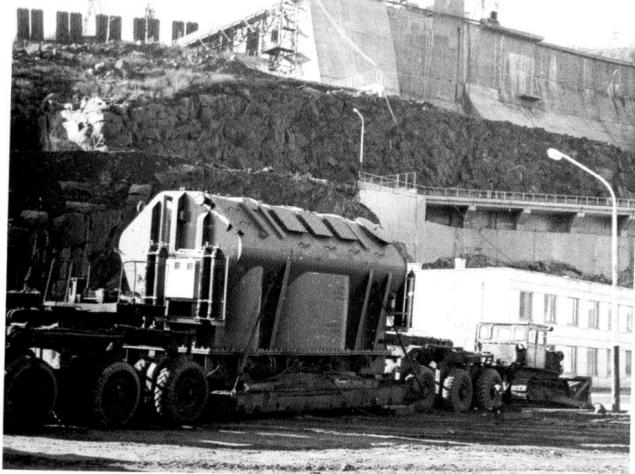

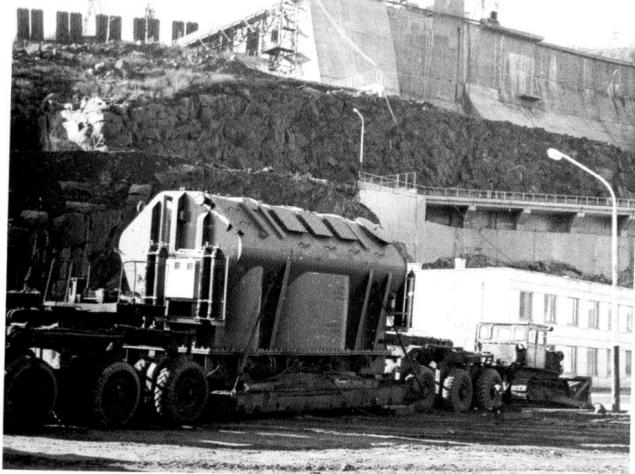

Delivery transformer

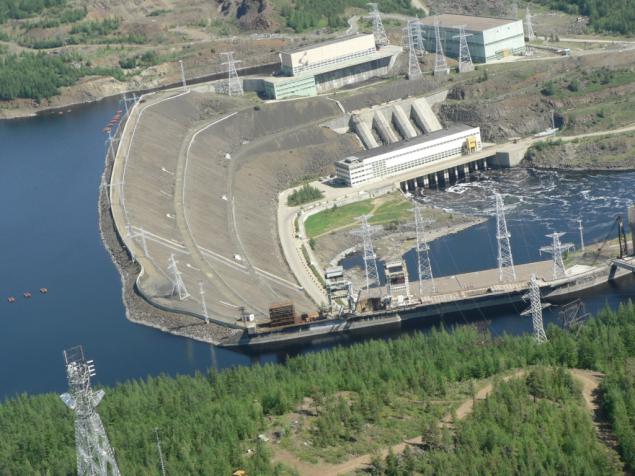

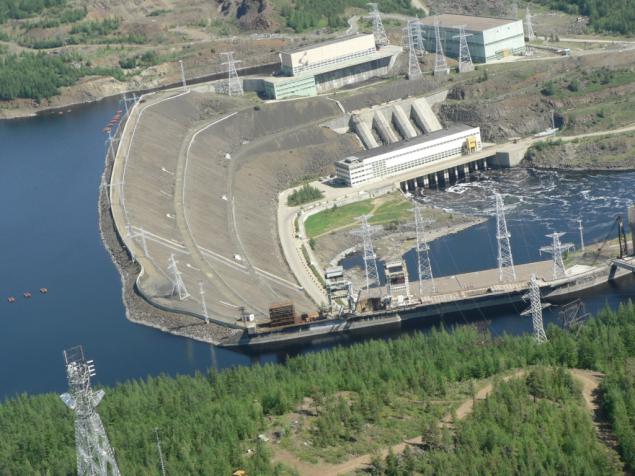

Modern look

GES-1 hydroelectric generator

Computer room HPP-2

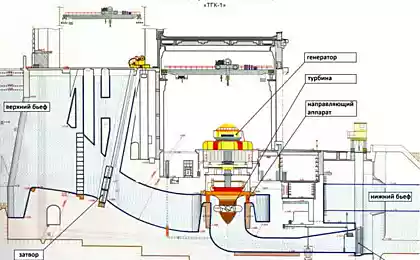

Incision along the axis of hydroelectric stations: Water from the upper pool that the water enters the volute and results in rotation of the impeller wheel in turn rigidly attached to the rotor during rotation which is produced electricity

And here is the very turbine wheel

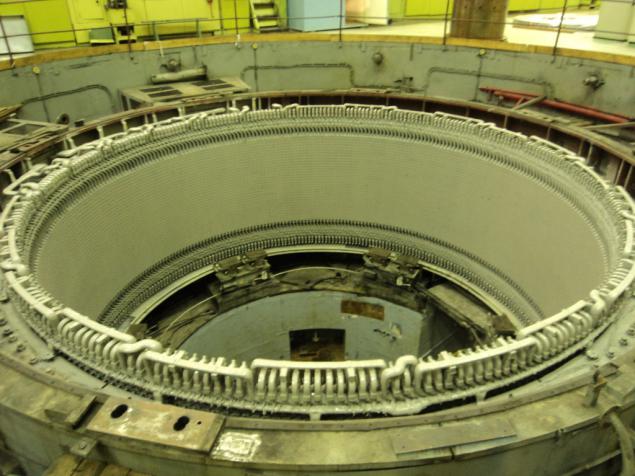

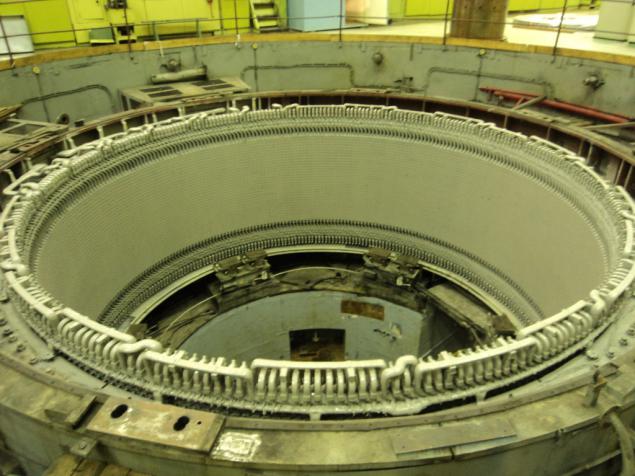

And this is the stator within which the rotor is spinning

And here is the rotor that rotates inside the stator 187 with a speed 5 rpm and the gap between the stator and the rotor is not more than 20 mm and not less than 5 mm

Panel automation - as postroili- way it works

Modern turbine speed control - it is responsible for the frequency of 50 Hz. This control is managed using a free system Windows CE

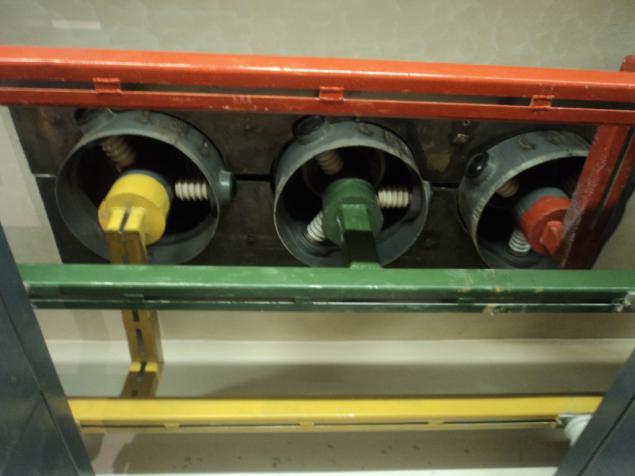

Busbar from hydro - rated current of 4200 amps for short circuit over 20,000 Amps

Busway runs from the stator through the switch to the transformer, where the generator voltage is increased to 13,800 volts 220,000 volts.

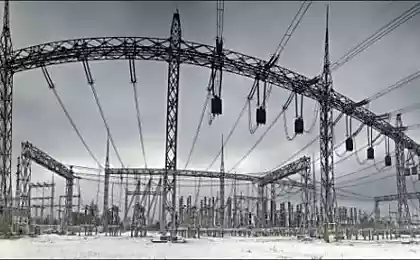

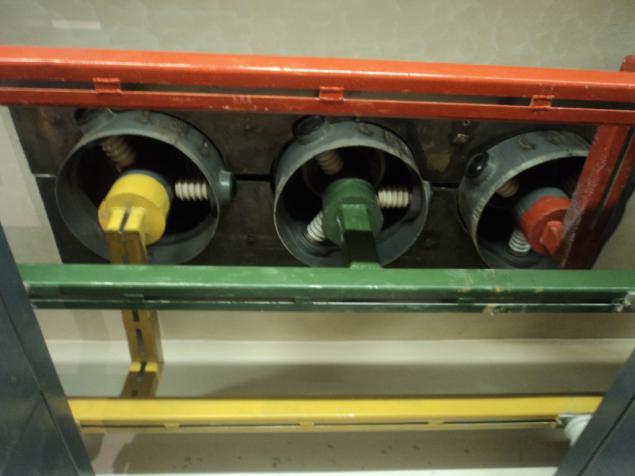

With all of the transformer on the wire enters the ISG-220 (indoor switchgear voltage 220,000 volts) which establishes such air switches CDH-220 (they are controlled by air to 20 atmospheres)

Phone for direct connection to the main control board (main control room)

The main control panel from the time of construction in 1965 has never changed

The most important instrument in the MCR - frequency. Ideally, there should always be 50 Hz.

I almost forgot to mash.zale HPP-2 grow tangerines and it's not photoshop.

Night photo of the dam - this is the last PHOTO - can kick

Source:

Composition hydroelectric facilities: dam 600 m long and 75 m maximum height

Power HPP - 680 MW,.

The building HPP-I has 4 Kaplan hydro capacity of 85 MW

The building HES-II has 4 Francis hydro capacity of 85 MW.

From the station, laid 5 220 kV transmission lines in the Lena through peaceful, and with a successful Aikhal.

Viluiskaya HPP gave the opportunity to start a large-scale development of diamond deposits in Yakutia. The main consumer of electricity is JSC "ALROSA". Cost of 1 kWh of electricity in 2013 - 90 kopecks.

Viluiskaya HPP was built in extremely difficult conditions of permafrost. Many designs were worked out for the first time.

29 photos will be

The beginning of construction in 1960

Laying the foundation of loam in the dam - everything happens at subzero temperatures

Construction of the first stage of HPP-1

Again blow the dam - is seen as the ground is heated with a heat gun, and then ukatyvayut laden dump trucks. By stacking technology made in the winter and now round the dam has an internal temperature of minus 5, 5. In fact - the dam huge chunk of frozen clay

What used to be a beautiful girl!

Volute hydroelectric

Pouring concrete using Zielke - there was no cement

Start of construction of the receiving water

There soon will flood all

Flooding water intake HPP-1

Delivery transformer

Modern look

GES-1 hydroelectric generator

Computer room HPP-2

Incision along the axis of hydroelectric stations: Water from the upper pool that the water enters the volute and results in rotation of the impeller wheel in turn rigidly attached to the rotor during rotation which is produced electricity

And here is the very turbine wheel

And this is the stator within which the rotor is spinning

And here is the rotor that rotates inside the stator 187 with a speed 5 rpm and the gap between the stator and the rotor is not more than 20 mm and not less than 5 mm

Panel automation - as postroili- way it works

Modern turbine speed control - it is responsible for the frequency of 50 Hz. This control is managed using a free system Windows CE

Busbar from hydro - rated current of 4200 amps for short circuit over 20,000 Amps

Busway runs from the stator through the switch to the transformer, where the generator voltage is increased to 13,800 volts 220,000 volts.

With all of the transformer on the wire enters the ISG-220 (indoor switchgear voltage 220,000 volts) which establishes such air switches CDH-220 (they are controlled by air to 20 atmospheres)

Phone for direct connection to the main control board (main control room)

The main control panel from the time of construction in 1965 has never changed

The most important instrument in the MCR - frequency. Ideally, there should always be 50 Hz.

I almost forgot to mash.zale HPP-2 grow tangerines and it's not photoshop.

Night photo of the dam - this is the last PHOTO - can kick

Source: