868

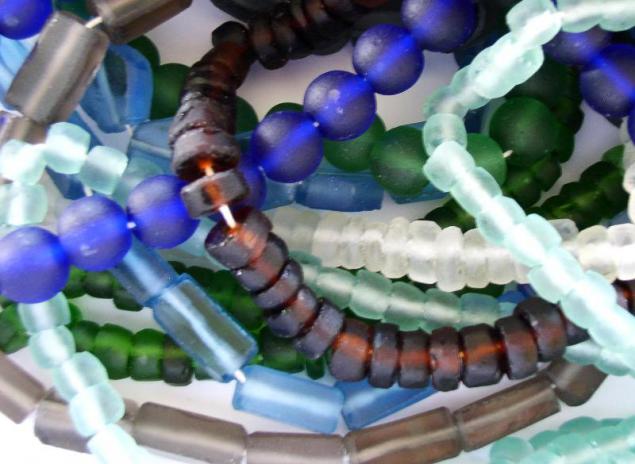

African beads bottle glass.

Writes sirickss:

Those of us who are closely involved in the creation of jewelry, or prefer to wear them and understand the fashion and style, knows how valuable unique rare materials. Admit it, you've spent more than one hour, considering the book or going from site to site in search of rare beads, copyright, vintage or ethnic.

Today I want to talk about some kinds of glass beads African. And, I do not want to talk about the history of their appearance, more everything is more or less clear, but it is about the practical side.

First of all these amazing colors and designs stёklyshki unusual in that many of them are made of glass bottle!

Under the cut - a huge number of pictures of their manufacturing process, photographs of finished products, as well as video.

In this review, I will not touch the African counterpart millefiori inherent in more Kenyan craftsmen and discuss basic techniques for working with crushed glass bottle used in Krobia.

Krobia - an area in Ghana, a relatively large center of modern production of beads with a variety of workshops.

They produce beads of five main types:

- Beads powder (powdered glass beads)

- Transparent beads (translucent beads)

- Painted beads (painted glass beads)

- Beads (seed beads)

- Bodum bead (??? chevrons did not understand and did not find enough information

When using the powder obtained by the classic footy embroidered beads. In fairness, I note that they are not all necessarily made of bottles, but often it is. Also use window glass, car headlights, etc., in short, any glass recyclables.

This is done as follows.

Bottles cleaned and possibly washed, sorted by color.

Then pounded in a mortar high.

The finer fraction obtained by grinding glass sand between two stones.

And periodically sieved powder was triturated again until the powder will not be as thin as possible.

Of course, all this is done manually.

Make a ceramic mold with indentations.

...

The forms are dried, roasted and immediately before filling the glass cell, the entire form is covered with kaolin (a kind of clay, the main component of the porcelain) preventing sintering of the glass to form and dried. This coating is periodically renewed.

In large workshops plurality of such forms, of different sizes and configurations.

In the center of form for beads of powder sometimes make a small indentation:

In order to get a bead with a hole in the center of the form is placed floral twig (manioc stalks).

Heat treatment takes place fairly quickly and at low temperature, so the glass powder is not converted into a homogeneous piece extending out of molten glass, a grain of sand was hot for each other as in fusing.

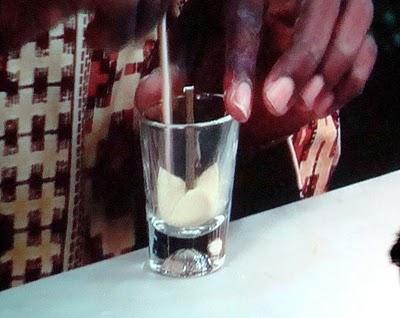

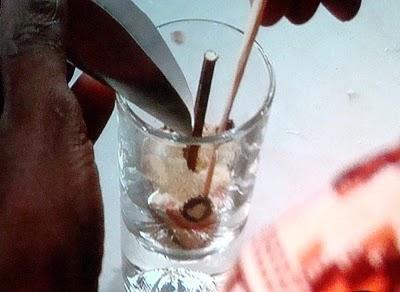

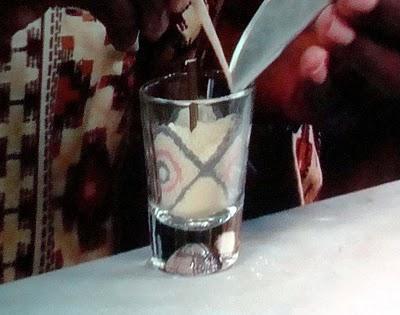

Multi-colored powder is filled into the mold layer by layer on the same principle as in the Egyptian souvenir bottles filled with colored sand. The pattern is formed this way, cold way.

For clarity of the pictures, as it happens, but in a glass:

...

...

...

...

That is how the filling of forms to beads.

The mold is then sent to the furnace.

Hellish structure made of local red clay, wood stoked

Flaps conditional protect from direct heat during operation.

The temperature there is relatively low (600-800grad), so the glass is sintered only partially bead remains murky and grains of glass are easily distinguishable.

The temperature is determined by the master on the eyes, the color of melting glass.

Stem fade, leaving a smooth bead hole:

The furnace is in the form during 20-45 minutes depending on the temperature and size of the product.

The idea then would be nice to make a joke (standing up on the melting temperature of glass (about 550grad) for uniform distribution of molecules and stress relief), but given the nature of technology and the workplace, African masters do without it.

In today's large furnaces for Huta near the crucible filled with molten glass, there is a place ler, which is folded and molded products for annealing. Maybe sometimes they do the same, but more often simply leave the beads to cool slowly in the mold.

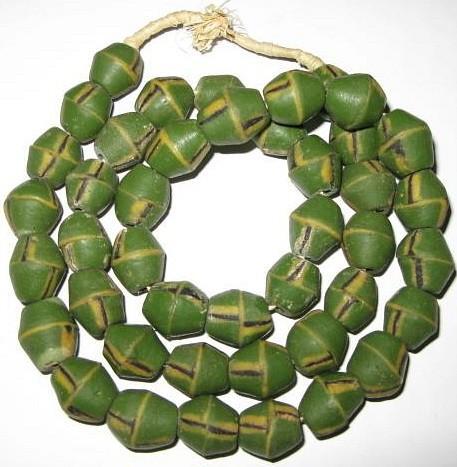

To make here are biconical beads ...

... First of two powder sintered patterned cone, then skewer them on the same plant twig and sintered both halves. Presumably, at a slightly lower temperature.

...

Solid beads of powder paint ceramic paints (a solution of clay with colored glass powder), dried, lay in the same molds and fired again.

Figure Apply a thin stick or a needle.

...

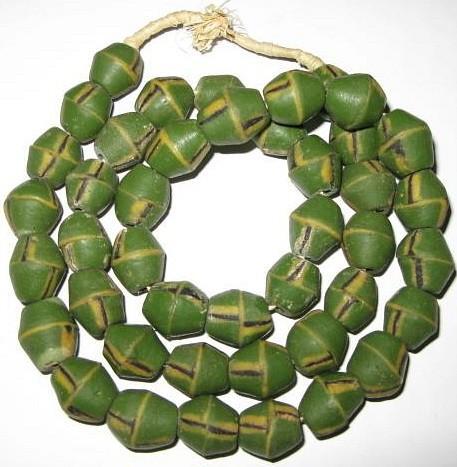

Obtained recognizable pёstnye bright beads with specific patterns.

...

Posted in [mergetime] 1306584364 [/ mergetime]

The video, shot one of the workshops:

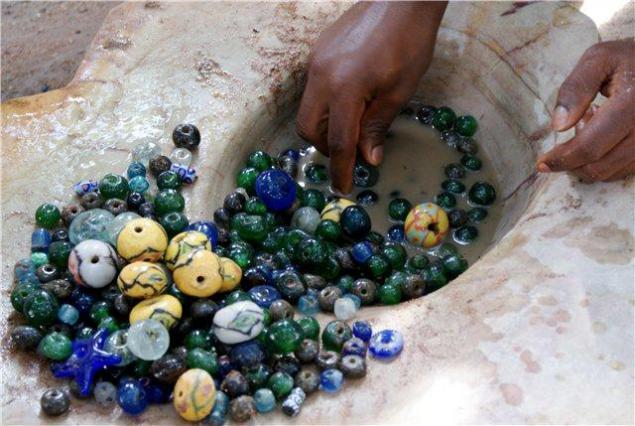

Beads of the larger pieces of glass are made of similar form, except that they do not have recess in the center for cassava twig. The cells serve as a measuring cup for a more or less equal-sized beads, crucibles for melting glass and boards for rolling at the same time.

To begin the mold is filled monochrome or suitable to mix (given coefficient of thermal expansion, recognizable in practice) of crushed glass.

Then sent to the furnace at a slightly longer time and higher temperature than the beads of powder.

Upon reaching the desired degree of softness of the glass, the form is removed and quickly formed beads, working two shilami. First are holding a ceramic form, the second pierced the glass mass and quickly scroll through it, pressing to form steknkam to bead steel round

...

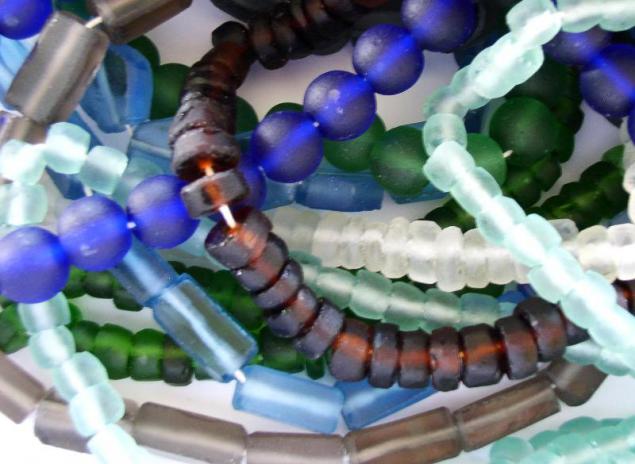

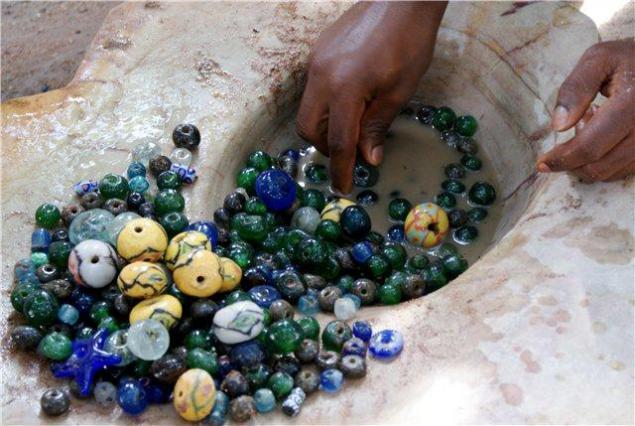

And they both beads after cooling is ground on the stone with water and sand. How? Hands, of course: - /

After polishing beads oiled machinery or plant food.

Beads from a simple broken glass are more or less transparent, but the glass particles sometimes still distinguishable (in the case of insufficient heat):

...

The beads are easily recognized color bottle, but that they have not become less beautiful in their naivety and primitive simplicity.

...

...

...

...

...

These beads, as well as their products, are available at the Internet-shops and e-bay.

Next - a small gallery of jewelry made with these amazing beads, with the assembly not only ethnic, but also European and American authors.

...

...

...

...

...

...

...

...

...

...

via sirickss LJ

Source:

Those of us who are closely involved in the creation of jewelry, or prefer to wear them and understand the fashion and style, knows how valuable unique rare materials. Admit it, you've spent more than one hour, considering the book or going from site to site in search of rare beads, copyright, vintage or ethnic.

Today I want to talk about some kinds of glass beads African. And, I do not want to talk about the history of their appearance, more everything is more or less clear, but it is about the practical side.

First of all these amazing colors and designs stёklyshki unusual in that many of them are made of glass bottle!

Under the cut - a huge number of pictures of their manufacturing process, photographs of finished products, as well as video.

In this review, I will not touch the African counterpart millefiori inherent in more Kenyan craftsmen and discuss basic techniques for working with crushed glass bottle used in Krobia.

Krobia - an area in Ghana, a relatively large center of modern production of beads with a variety of workshops.

They produce beads of five main types:

- Beads powder (powdered glass beads)

- Transparent beads (translucent beads)

- Painted beads (painted glass beads)

- Beads (seed beads)

- Bodum bead (??? chevrons did not understand and did not find enough information

When using the powder obtained by the classic footy embroidered beads. In fairness, I note that they are not all necessarily made of bottles, but often it is. Also use window glass, car headlights, etc., in short, any glass recyclables.

This is done as follows.

Bottles cleaned and possibly washed, sorted by color.

Then pounded in a mortar high.

The finer fraction obtained by grinding glass sand between two stones.

And periodically sieved powder was triturated again until the powder will not be as thin as possible.

Of course, all this is done manually.

Make a ceramic mold with indentations.

...

The forms are dried, roasted and immediately before filling the glass cell, the entire form is covered with kaolin (a kind of clay, the main component of the porcelain) preventing sintering of the glass to form and dried. This coating is periodically renewed.

In large workshops plurality of such forms, of different sizes and configurations.

In the center of form for beads of powder sometimes make a small indentation:

In order to get a bead with a hole in the center of the form is placed floral twig (manioc stalks).

Heat treatment takes place fairly quickly and at low temperature, so the glass powder is not converted into a homogeneous piece extending out of molten glass, a grain of sand was hot for each other as in fusing.

Multi-colored powder is filled into the mold layer by layer on the same principle as in the Egyptian souvenir bottles filled with colored sand. The pattern is formed this way, cold way.

For clarity of the pictures, as it happens, but in a glass:

...

...

...

...

That is how the filling of forms to beads.

The mold is then sent to the furnace.

Hellish structure made of local red clay, wood stoked

Flaps conditional protect from direct heat during operation.

The temperature there is relatively low (600-800grad), so the glass is sintered only partially bead remains murky and grains of glass are easily distinguishable.

The temperature is determined by the master on the eyes, the color of melting glass.

Stem fade, leaving a smooth bead hole:

The furnace is in the form during 20-45 minutes depending on the temperature and size of the product.

The idea then would be nice to make a joke (standing up on the melting temperature of glass (about 550grad) for uniform distribution of molecules and stress relief), but given the nature of technology and the workplace, African masters do without it.

In today's large furnaces for Huta near the crucible filled with molten glass, there is a place ler, which is folded and molded products for annealing. Maybe sometimes they do the same, but more often simply leave the beads to cool slowly in the mold.

To make here are biconical beads ...

... First of two powder sintered patterned cone, then skewer them on the same plant twig and sintered both halves. Presumably, at a slightly lower temperature.

...

Solid beads of powder paint ceramic paints (a solution of clay with colored glass powder), dried, lay in the same molds and fired again.

Figure Apply a thin stick or a needle.

...

Obtained recognizable pёstnye bright beads with specific patterns.

...

Posted in [mergetime] 1306584364 [/ mergetime]

The video, shot one of the workshops:

Beads of the larger pieces of glass are made of similar form, except that they do not have recess in the center for cassava twig. The cells serve as a measuring cup for a more or less equal-sized beads, crucibles for melting glass and boards for rolling at the same time.

To begin the mold is filled monochrome or suitable to mix (given coefficient of thermal expansion, recognizable in practice) of crushed glass.

Then sent to the furnace at a slightly longer time and higher temperature than the beads of powder.

Upon reaching the desired degree of softness of the glass, the form is removed and quickly formed beads, working two shilami. First are holding a ceramic form, the second pierced the glass mass and quickly scroll through it, pressing to form steknkam to bead steel round

...

And they both beads after cooling is ground on the stone with water and sand. How? Hands, of course: - /

After polishing beads oiled machinery or plant food.

Beads from a simple broken glass are more or less transparent, but the glass particles sometimes still distinguishable (in the case of insufficient heat):

...

The beads are easily recognized color bottle, but that they have not become less beautiful in their naivety and primitive simplicity.

...

...

...

...

...

These beads, as well as their products, are available at the Internet-shops and e-bay.

Next - a small gallery of jewelry made with these amazing beads, with the assembly not only ethnic, but also European and American authors.

...

...

...

...

...

...

...

...

...

...

via sirickss LJ

Source: