501

How do the bottles

How many of us, pouring into the glasses bitter, think about, but as this bottle was made?

School glassblower will not open, but in two or three words and I will tell you this is quite not an easy process.

The link to the source did not bring because, as they say, the music and the words of the people that my.

Perhaps I'll start. Sand.

Who is not in the subject - making glass from sand. But there is not any sand from the beach, and especially (I admit even

Do not know where to take this) grains are all one to one, melenkie, accurate and in any case no dust.

Needless to sand Saboya added various materials such as dolomite, chalk (limestone), and dyes, to impart various glass

properties.

Posted in [mergetime] 1303601124 [/ mergetime]

For example, to add brown glass iron oxide for green - chrome, and aluminum sulfate for white.

Also, to the main components are mixed in a fair amount of caustic soda, (but this is for lowering the melting point

sand). In general, all this stirred hefty mixer and adding the desired color of broken glass on the conveyor lines sent

closer to the glass furnace.

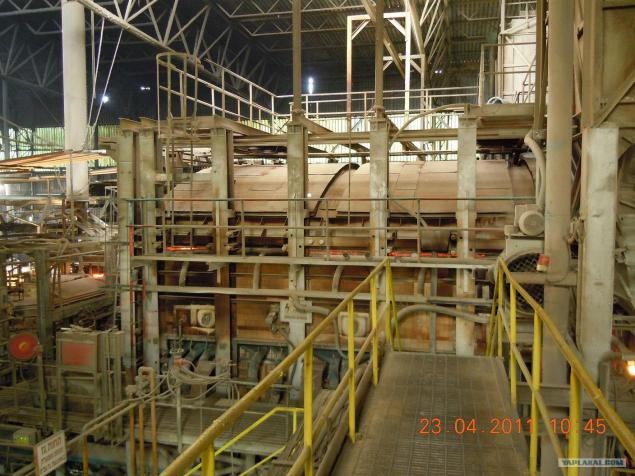

That's actually the very oven. To attach it Khalabuda any many more, but the bulk of it here.

Furnaces have different sizes, but particularly the 270 tons. Pecs and installed with a slight slope, so that glass flows by gravity.

And this is a mixture of sand gets inside the oven.

Gehenna

She

degrees in 1580

Battery fuel oil nozzles for the upper heating.

Since the depth of the liquid glass in the furnace about fifteen meters, its temperature near the bottom estesstvenno much lower, and that's what would equate

temperature below the glass is heated with electricity (12 molybdenum electrodes with a thickness of a hand).

But since the oven looks from the inside.

Through this neck of the glass flows out.

And this is what happens with silicate blocks under the influence of temperature and constant current window.

and here

Ceiling.

Managed by the whole rigmarole here.

and hence

That's the way the transition from white to green glass.

So, go ahead. On this sleeve (there are 4), the glass gets to razduvochnuyu car.

A stream of glass cut special miracle scissors

and a drop of liquid glass on the guide goes into its mold

blowing

and this is also

and it

Once the bottle is ready, it must go through ohlazhdayushuyu oven, that would remove the internal stress of the glass. Without this

procedures bottle explode even a light touch.

At the exit of the cooling furnace bottles need to sprinkle a special solution that could become slippery. Try rubbing

one bottle for another, if they do not slip and leave scratches on each other, so spraying was complete.

Then all the bottles pass through special devices to check for defects.

Finally get on the packaging line, where they are placed on pallets, lay cardboard, sealed in plastic and a warehouse.

...

...

...

Thank you for attention!

Source:

School glassblower will not open, but in two or three words and I will tell you this is quite not an easy process.

The link to the source did not bring because, as they say, the music and the words of the people that my.

Perhaps I'll start. Sand.

Who is not in the subject - making glass from sand. But there is not any sand from the beach, and especially (I admit even

Do not know where to take this) grains are all one to one, melenkie, accurate and in any case no dust.

Needless to sand Saboya added various materials such as dolomite, chalk (limestone), and dyes, to impart various glass

properties.

Posted in [mergetime] 1303601124 [/ mergetime]

For example, to add brown glass iron oxide for green - chrome, and aluminum sulfate for white.

Also, to the main components are mixed in a fair amount of caustic soda, (but this is for lowering the melting point

sand). In general, all this stirred hefty mixer and adding the desired color of broken glass on the conveyor lines sent

closer to the glass furnace.

That's actually the very oven. To attach it Khalabuda any many more, but the bulk of it here.

Furnaces have different sizes, but particularly the 270 tons. Pecs and installed with a slight slope, so that glass flows by gravity.

And this is a mixture of sand gets inside the oven.

Gehenna

She

degrees in 1580

Battery fuel oil nozzles for the upper heating.

Since the depth of the liquid glass in the furnace about fifteen meters, its temperature near the bottom estesstvenno much lower, and that's what would equate

temperature below the glass is heated with electricity (12 molybdenum electrodes with a thickness of a hand).

But since the oven looks from the inside.

Through this neck of the glass flows out.

And this is what happens with silicate blocks under the influence of temperature and constant current window.

and here

Ceiling.

Managed by the whole rigmarole here.

and hence

That's the way the transition from white to green glass.

So, go ahead. On this sleeve (there are 4), the glass gets to razduvochnuyu car.

A stream of glass cut special miracle scissors

and a drop of liquid glass on the guide goes into its mold

blowing

and this is also

and it

Once the bottle is ready, it must go through ohlazhdayushuyu oven, that would remove the internal stress of the glass. Without this

procedures bottle explode even a light touch.

At the exit of the cooling furnace bottles need to sprinkle a special solution that could become slippery. Try rubbing

one bottle for another, if they do not slip and leave scratches on each other, so spraying was complete.

Then all the bottles pass through special devices to check for defects.

Finally get on the packaging line, where they are placed on pallets, lay cardboard, sealed in plastic and a warehouse.

...

...

...

Thank you for attention!

Source: