424

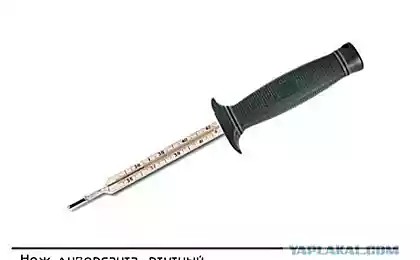

Knife tanto

He asked me one good man to make a gift to another good man knife. Well, the point is usual, and in some cases even simple enough already ... but I was immediately "landed" - the customer wanted "something like a wakizashi." Took estimate - have realized that it is very off-budget, and the deadline is running out for this project, but the most important thing - I do not know anything about nicherta YAIHO! * As the saying goes - at hand is gone! In general we agreed that we needed a Aykut or tanto (both term anyone can google). What came of it - see 9 photos (please do not break).

* Japanese historical edged weapons

For starters we order from a friend blacksmith armourer blade. TTX blade: 170h25h4 mm in cross-section - a diamond 5 polyhedron with a slightly concave slopes, mixed by zero, had to work very carefully, so as not to cause injury. Steel smith I have not called, but I believe that it is uglerodka some or U8 or U10, but a cunning way forged and termichenaya because the feature line quenching - jamon, both of Japanese blades is not particularly visible, but got very beautiful "damask" pattern that will be seen next. Hardness feelings about 57-58 units HRC.

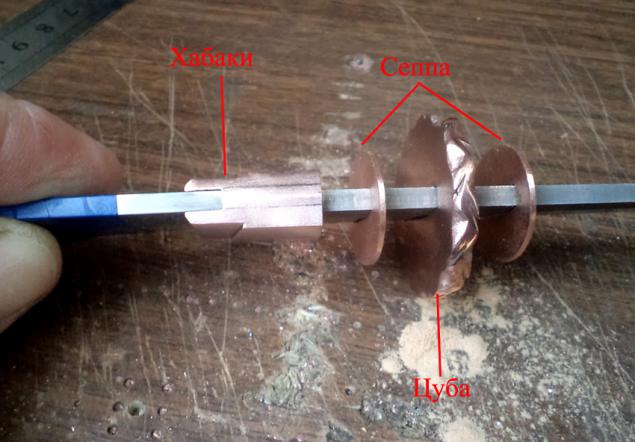

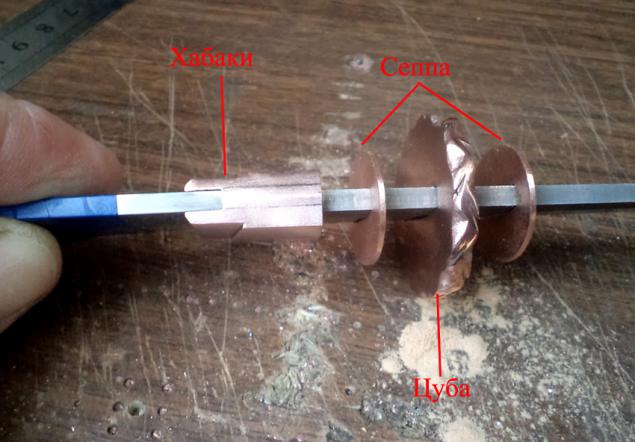

Next, you need to make accessories. He started with soldering Khabakov. This process fotkal I did not, and so it was for both "Merfologii" - to perform most operations require three hands! Khabakov consists of 3 parts, soldered copper-silver solder. Material - Copper 3, 5 mm. Sepp - copper 1, 5mm, tsuba - copper 5mm. On tsube using Needle sliced faylvork. All this Grind kratsovochnoy soft brush to give a specific texture of copper. Further, the composition was taken to bluing metal "Clover" and patinated copper them to black and then felt the excess coating has been removed. All planting cuts meticulous detail, without play and slack, customized needle files under the shank of the blade.

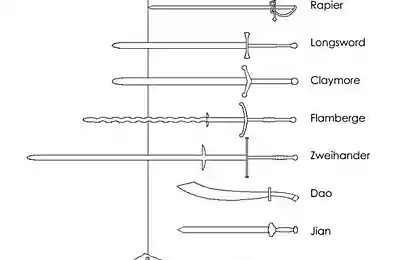

to make it clear - that where and how

The material for the manufacture of the handle (tsuka) and sheath (saya) served laysvud. The handle propyl fit under liner - that still eblya with dancing and I still gaps about the ... weak, but it is solved: epoxy clay and shank oiled lithologic saved the day - no longer handle the backlash in the assembly of the knife together. Just do something, according to the canons of manufacture and handle and sheath are assembled from two halves, then glued together, but laysvuda tricky texture and I did not want it to spoil, sawn bar. Here with scabbard - no options, there is a wedge hole will not choose "blind", so the two were glued plates with sampling locations on the blade and Khabakov, by which the knife is held in a sheath. Wood sanded to 2000 grid, polished with carnauba wax and coated with shellac. Mekugi (stick in the handle holding the entire structure) -from bamboo.

...

Well, the results

...

...

...

and in his hand

Posted in [mergetime] 1355989236 [/ mergetime]

That I once took for such an order - danunakuy !!!

It did not quite authentic, not by the canons, but the client was very good. happy, and this is important!

Source:

* Japanese historical edged weapons

For starters we order from a friend blacksmith armourer blade. TTX blade: 170h25h4 mm in cross-section - a diamond 5 polyhedron with a slightly concave slopes, mixed by zero, had to work very carefully, so as not to cause injury. Steel smith I have not called, but I believe that it is uglerodka some or U8 or U10, but a cunning way forged and termichenaya because the feature line quenching - jamon, both of Japanese blades is not particularly visible, but got very beautiful "damask" pattern that will be seen next. Hardness feelings about 57-58 units HRC.

Next, you need to make accessories. He started with soldering Khabakov. This process fotkal I did not, and so it was for both "Merfologii" - to perform most operations require three hands! Khabakov consists of 3 parts, soldered copper-silver solder. Material - Copper 3, 5 mm. Sepp - copper 1, 5mm, tsuba - copper 5mm. On tsube using Needle sliced faylvork. All this Grind kratsovochnoy soft brush to give a specific texture of copper. Further, the composition was taken to bluing metal "Clover" and patinated copper them to black and then felt the excess coating has been removed. All planting cuts meticulous detail, without play and slack, customized needle files under the shank of the blade.

to make it clear - that where and how

The material for the manufacture of the handle (tsuka) and sheath (saya) served laysvud. The handle propyl fit under liner - that still eblya with dancing and I still gaps about the ... weak, but it is solved: epoxy clay and shank oiled lithologic saved the day - no longer handle the backlash in the assembly of the knife together. Just do something, according to the canons of manufacture and handle and sheath are assembled from two halves, then glued together, but laysvuda tricky texture and I did not want it to spoil, sawn bar. Here with scabbard - no options, there is a wedge hole will not choose "blind", so the two were glued plates with sampling locations on the blade and Khabakov, by which the knife is held in a sheath. Wood sanded to 2000 grid, polished with carnauba wax and coated with shellac. Mekugi (stick in the handle holding the entire structure) -from bamboo.

...

Well, the results

...

...

...

and in his hand

Posted in [mergetime] 1355989236 [/ mergetime]

That I once took for such an order - danunakuy !!!

It did not quite authentic, not by the canons, but the client was very good. happy, and this is important!

Source: