864

House of SIP-panels

To create this psto, prompted the theme of "What cost us build a house ...", two wonderful, rukastogo guys.

I like a man who loves construction and they are engaged in the topic butted.

The personal questions went - pretty much.

I thought and thought, decided to tell you how you can build a house for 900K, within a month.

The post will be about ~ 30 photos

Well, it is interesting - I will answer all the questions as possible.

And so, once, in 2011, in the spring - there were my customers.

Middle-aged, married couple. Live life in the city, and retirement - have decided to sell the city kopeck piece, so - to build a house.

Ingenuously confessed, saying the apartment was sold for 2.8kk, but want to keep on a construction site in 1kk allegedly "300-400 thousand to finish 300-400 thousand for furniture and to a million was on deposit, granddaughter inherited»

The site they had.

What - not a trivial task, but I have a gambling man, so started.

Generally, the selection of the project will lower, and so on.

And so, we begin.

The post will be about 30-40 photos, text Troshkov.

Well, it is interesting - I will answer all the questions as possible.

Early August.

We arrived at the station, settled their guys (kindly provided by the customer home, even his grandfather)

Here in this place - will be home in a half floors and a 136m2 area.

White animal - a dog Kesha, which (attention) known only 22 years of age.

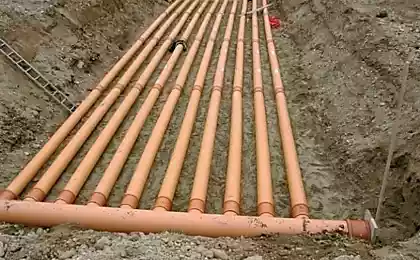

The next day, using the cord marked out pile field, drove the pegs on the future site of the foundation, and for a half day hardboiled 23 piles with a diameter of 110 mm and a length of 3 meters.

In the photo - preparation for pouring piles conventional cement mortar.

While these works were carried out, the customer had dug two Tajiks. pit under the pump to deliver water from the well. In principle - the photo shows the pile of sand.

It piles welded square end cap, 200x200, vertical studs are inserted with the release in 300mm, which planted timber size 200h200mm.

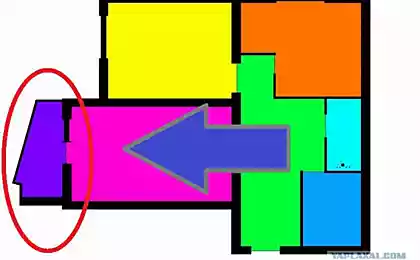

This is the skeleton of the zero level of the future house.

Bruce processed homemade impregnation, based on mining, washing powder and boric acid)

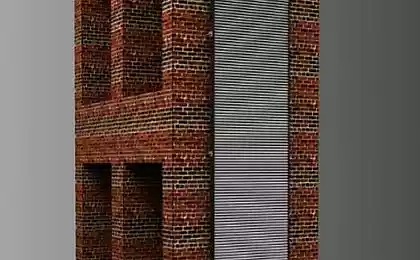

In the distance can be seen the future walls, floors and roof of the house.

View from another angle.

Basically, when using SIP does not require any steep machines, cranes, laser levels and other nanotechnology.

The most precise instruments in the world - it plummet and gidrouroven.))

A rest day, and started.

On obvzyaochny timber stacked panel sip-zero level (he floor 1st floor)

Panel thickness - 226mm, in principle, is more than enough.

The panels are interconnected mortgage Log dimensions 100h150mm. They serve as additional reinforcement floor.

DFC - well - withdrawn corners of the walls of the first floor.

In SIP- building walls chased from the corners to the doorway. It's faster and easier.

Yes, still - this 9th day of construction.

And the horizon is filled up))

Chase walls, simultaneously closes mortgage timbers angles and output window openings.

The important point, cool and easier.

If correctly and clearly in terms of the angles to set, how they say "whip and whip", because errors panels - are minimal.

More photos.

View from inside.

Derived interior walls.

Day 15-17 was devoted to installing floors.

The principle is the same as zero overlap.

The difficult part of the job, maybe each panel weighs more than 100 kg, and no mechanization))

Fortunately there are lots of old-fashioned way, by means of which the work easier at times.

The film, which is visible in the photo - sheltered overlap Short rain. In principle, the panel it is not terrible, but it was trite lazy to pull off downward extensions, screwdrivers, and other remanent.

Rested for 2 days, in connection with which the local festivities and went to do the 2nd floor.

In the photo is clearly seen protruding central beam, which will be stowed roof ridge.

SPIL all unnecessary corners, laid skate and here it is - the roof.

Too hard part of the job, maybe, the height is already rather big, too heavy panels.

But to the right.

Day 26)

The next 5 days left for the installation of chimney, roof soft tile iotdelku Shinglas and cleaning hellish sracha inherent in every construction site.

Here it is - the house.

The windows are inserted hour later)

Bonus

From the first days of construction, the guys here such StroyTehNadzor pribludy)))

I climbed the entire construction site where no hitting.

Posted in [mergetime] 1365670756 [/ mergetime]

Actually, that's it.

Final

Number of employees: 3-4 people, 2 of which "bring-feed»

Budget: 900K with the work.

100 spent on the channel, the water supply and electrical wiring.

31 or 32 days, I'm afraid to tell lies - was spent on the job.

The first winter, the customer electrician to heat the house.

Scores - minuscule, maybe the house is really very warm.

It seems like everything I wanted to write.

Thank you all.

Source:

I like a man who loves construction and they are engaged in the topic butted.

The personal questions went - pretty much.

I thought and thought, decided to tell you how you can build a house for 900K, within a month.

The post will be about ~ 30 photos

Well, it is interesting - I will answer all the questions as possible.

And so, once, in 2011, in the spring - there were my customers.

Middle-aged, married couple. Live life in the city, and retirement - have decided to sell the city kopeck piece, so - to build a house.

Ingenuously confessed, saying the apartment was sold for 2.8kk, but want to keep on a construction site in 1kk allegedly "300-400 thousand to finish 300-400 thousand for furniture and to a million was on deposit, granddaughter inherited»

The site they had.

What - not a trivial task, but I have a gambling man, so started.

Generally, the selection of the project will lower, and so on.

And so, we begin.

The post will be about 30-40 photos, text Troshkov.

Well, it is interesting - I will answer all the questions as possible.

Early August.

We arrived at the station, settled their guys (kindly provided by the customer home, even his grandfather)

Here in this place - will be home in a half floors and a 136m2 area.

White animal - a dog Kesha, which (attention) known only 22 years of age.

The next day, using the cord marked out pile field, drove the pegs on the future site of the foundation, and for a half day hardboiled 23 piles with a diameter of 110 mm and a length of 3 meters.

In the photo - preparation for pouring piles conventional cement mortar.

While these works were carried out, the customer had dug two Tajiks. pit under the pump to deliver water from the well. In principle - the photo shows the pile of sand.

It piles welded square end cap, 200x200, vertical studs are inserted with the release in 300mm, which planted timber size 200h200mm.

This is the skeleton of the zero level of the future house.

Bruce processed homemade impregnation, based on mining, washing powder and boric acid)

In the distance can be seen the future walls, floors and roof of the house.

View from another angle.

Basically, when using SIP does not require any steep machines, cranes, laser levels and other nanotechnology.

The most precise instruments in the world - it plummet and gidrouroven.))

A rest day, and started.

On obvzyaochny timber stacked panel sip-zero level (he floor 1st floor)

Panel thickness - 226mm, in principle, is more than enough.

The panels are interconnected mortgage Log dimensions 100h150mm. They serve as additional reinforcement floor.

DFC - well - withdrawn corners of the walls of the first floor.

In SIP- building walls chased from the corners to the doorway. It's faster and easier.

Yes, still - this 9th day of construction.

And the horizon is filled up))

Chase walls, simultaneously closes mortgage timbers angles and output window openings.

The important point, cool and easier.

If correctly and clearly in terms of the angles to set, how they say "whip and whip", because errors panels - are minimal.

More photos.

View from inside.

Derived interior walls.

Day 15-17 was devoted to installing floors.

The principle is the same as zero overlap.

The difficult part of the job, maybe each panel weighs more than 100 kg, and no mechanization))

Fortunately there are lots of old-fashioned way, by means of which the work easier at times.

The film, which is visible in the photo - sheltered overlap Short rain. In principle, the panel it is not terrible, but it was trite lazy to pull off downward extensions, screwdrivers, and other remanent.

Rested for 2 days, in connection with which the local festivities and went to do the 2nd floor.

In the photo is clearly seen protruding central beam, which will be stowed roof ridge.

SPIL all unnecessary corners, laid skate and here it is - the roof.

Too hard part of the job, maybe, the height is already rather big, too heavy panels.

But to the right.

Day 26)

The next 5 days left for the installation of chimney, roof soft tile iotdelku Shinglas and cleaning hellish sracha inherent in every construction site.

Here it is - the house.

The windows are inserted hour later)

Bonus

From the first days of construction, the guys here such StroyTehNadzor pribludy)))

I climbed the entire construction site where no hitting.

Posted in [mergetime] 1365670756 [/ mergetime]

Actually, that's it.

Final

Number of employees: 3-4 people, 2 of which "bring-feed»

Budget: 900K with the work.

100 spent on the channel, the water supply and electrical wiring.

31 or 32 days, I'm afraid to tell lies - was spent on the job.

The first winter, the customer electrician to heat the house.

Scores - minuscule, maybe the house is really very warm.

It seems like everything I wanted to write.

Thank you all.

Source: