561

And we washed down the bed!

All the same, Yap spodvigaet on feats. What, actually, I did and saw on itself. Given: Old, creaky double bed 10 years ago. All good! But that's all faded prettiness, pooblupilas, cracked yes pooblomalas. Springs do not give sleep, and sounds are not allowed to show their passion in full scale! Resheno- will build a new one! It was build as a priority were as follows: To make it softness because the kids and I myself often about sharp corners put a bed bruises. Further, it should be beautiful. How does the aesthetics of our time is not the last thing. Next poslednee- and environmental friendliness. that is not all there to use chipboard and other chemical components. The strength and not to make it under the skripuchest- than spryatotsya in the bombardment and the neighbors do not wake ...

The old bed was sold at a price of 4 thousand per set, flew immediately. That she was ...

Next will be another 24 pictures, including one video.

Then we went to the hardware store, bought a 6-meter bar 10 * 15 6 m in length, and two 10 * 15 6 m, too.

Of these, 2 have made the blank piece 10 * 15 * 200 - the two bars are along the bed.

and three 10 * 10 * 140, these will lie perpendicular. Then I konesh slightly miscalculated over to do the bars along and across the I, but then recovered, all are not for sale do.

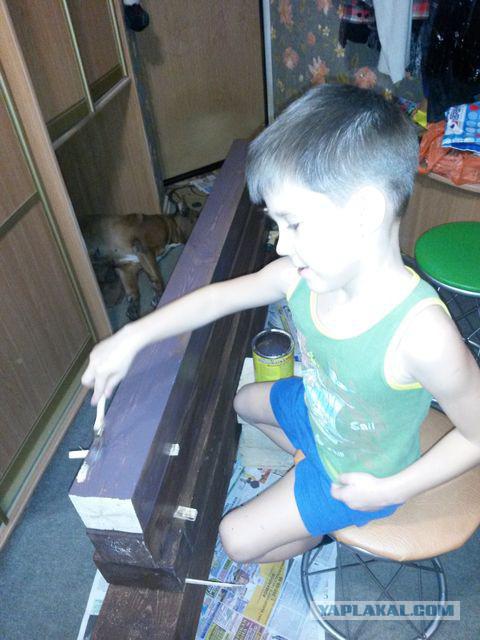

Especially on this occasion bought a grinder, as would not planed, flat still do not shop, and the machine has a bag of sawdust, and collects them like a vacuum cleaner. Polished rods covered with a special compound from fungi and other nasty things. It added to the dye, so that a quite nice :)

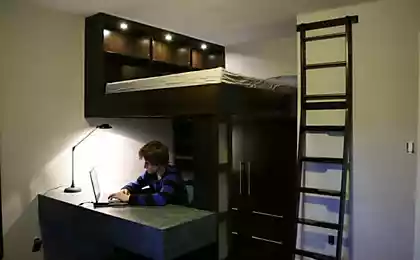

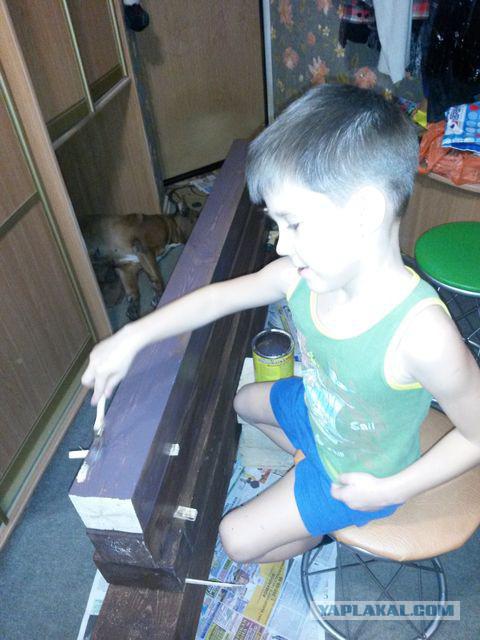

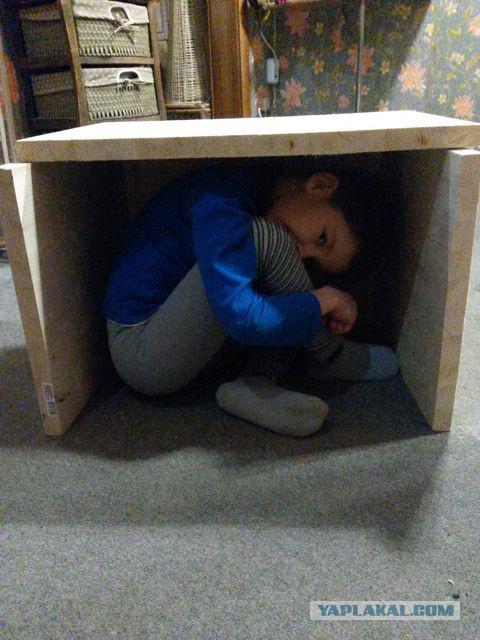

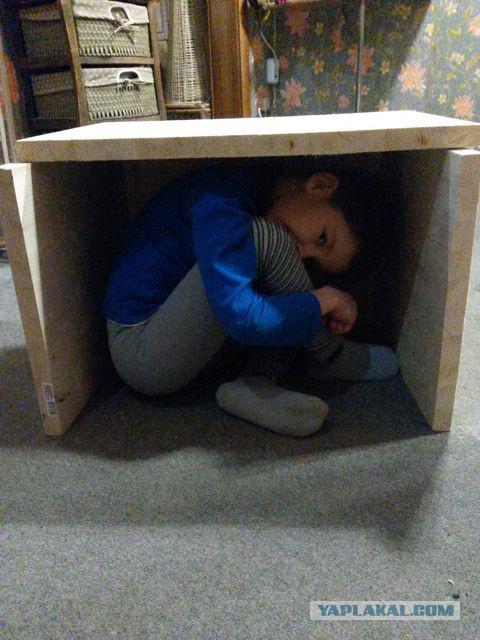

Assistants have a lot who is actively involved, someone passively :))

Forgot to say that all this is done while the mother is away, that is to say, a gift :))

Then buy a sheet of foam 10 200 * 20mm thick. And fabric furniture, local production plant "Iskozh»

Long sticks wrapped with foam, on top of a cloth. Everybody is attached to the stapler. Putting the frame.

We are putting it all on corners, ochchchchen good bolt.

Prepare internal cross

And here we get the base

even along the long bars reechki fasten plywood to maintain

Fanerku was taken at Leroy Merlin, there is sawn in size 140 * 100

On this first day ended, it began routine. Sections of the materials are intended for small naznacheniyu- builds a house :) :) A good start will be only plant a tree and raise a son :)

We came the next weekend, build more!

More materials were purchased on the side legs and the backrest. Feet made of 30 cm, attached with screws to the side fundamentals and reinforced corners.

Oh, and the previous photo in the middle of vstavochka dopolnenie- ... For durability and that plywood does not bend in the middle.

Large wooden boards found, stopped on the fact that you can dock the panel 2.

"Furniture wood panels" were bought at Castorama, 2 pcs 200 * 60 and 2 * 40 200 units of which were taken back by bonding and cutting :))

By stapler prishlepyvaem foam. At the head spinku- 60 mm, the one that legs- 20 mm. Moreover head obshlepyvayu backrest with only one hand, since the back will always rests against the wall, but the foot on both sides, as important and side view.

and the reverse side

Since he embroidering and sewing do not speak, I had to strain your friends and co-tailor and sew the side covers. Which have been put on the back and bottom of the fixed stapler. Just made ventilation in plywood. It turns already organic look :)

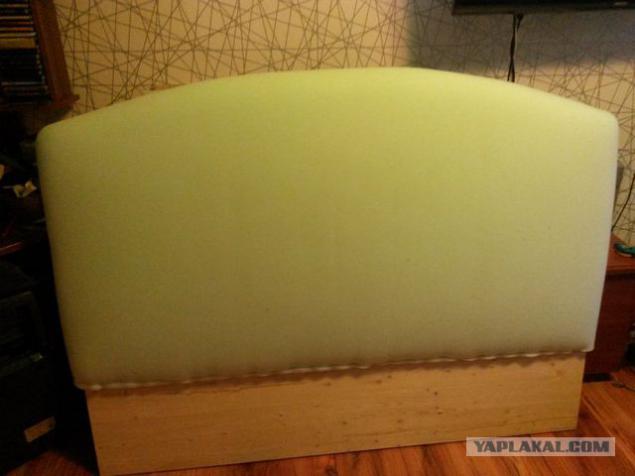

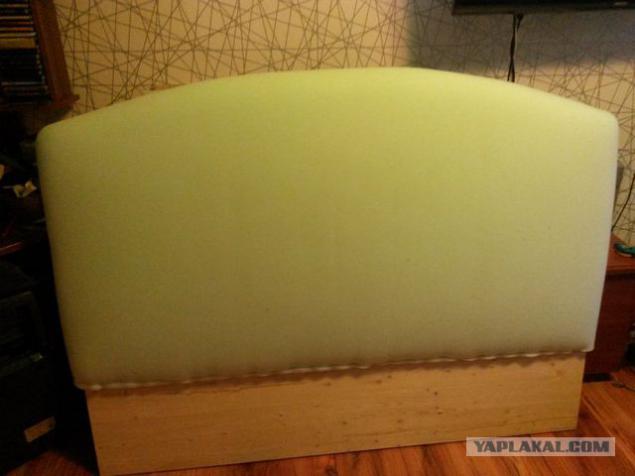

Try on the back of the head

We found the desk, which makes the embroidery on the fabric. All there chevrons, and so on. Made on the fabric headboard Picture

The result look like this :)

Well, if the rear view ... how strange twists the camera down. From the double bed seems single :)

Well, the bought in Ikeja Mattress 200 * 140 lay as though there is always lying!

And another angle

Source:

The old bed was sold at a price of 4 thousand per set, flew immediately. That she was ...

Next will be another 24 pictures, including one video.

Then we went to the hardware store, bought a 6-meter bar 10 * 15 6 m in length, and two 10 * 15 6 m, too.

Of these, 2 have made the blank piece 10 * 15 * 200 - the two bars are along the bed.

and three 10 * 10 * 140, these will lie perpendicular. Then I konesh slightly miscalculated over to do the bars along and across the I, but then recovered, all are not for sale do.

Especially on this occasion bought a grinder, as would not planed, flat still do not shop, and the machine has a bag of sawdust, and collects them like a vacuum cleaner. Polished rods covered with a special compound from fungi and other nasty things. It added to the dye, so that a quite nice :)

Assistants have a lot who is actively involved, someone passively :))

Forgot to say that all this is done while the mother is away, that is to say, a gift :))

Then buy a sheet of foam 10 200 * 20mm thick. And fabric furniture, local production plant "Iskozh»

Long sticks wrapped with foam, on top of a cloth. Everybody is attached to the stapler. Putting the frame.

We are putting it all on corners, ochchchchen good bolt.

Prepare internal cross

And here we get the base

even along the long bars reechki fasten plywood to maintain

Fanerku was taken at Leroy Merlin, there is sawn in size 140 * 100

On this first day ended, it began routine. Sections of the materials are intended for small naznacheniyu- builds a house :) :) A good start will be only plant a tree and raise a son :)

We came the next weekend, build more!

More materials were purchased on the side legs and the backrest. Feet made of 30 cm, attached with screws to the side fundamentals and reinforced corners.

Oh, and the previous photo in the middle of vstavochka dopolnenie- ... For durability and that plywood does not bend in the middle.

Large wooden boards found, stopped on the fact that you can dock the panel 2.

"Furniture wood panels" were bought at Castorama, 2 pcs 200 * 60 and 2 * 40 200 units of which were taken back by bonding and cutting :))

By stapler prishlepyvaem foam. At the head spinku- 60 mm, the one that legs- 20 mm. Moreover head obshlepyvayu backrest with only one hand, since the back will always rests against the wall, but the foot on both sides, as important and side view.

and the reverse side

Since he embroidering and sewing do not speak, I had to strain your friends and co-tailor and sew the side covers. Which have been put on the back and bottom of the fixed stapler. Just made ventilation in plywood. It turns already organic look :)

Try on the back of the head

We found the desk, which makes the embroidery on the fabric. All there chevrons, and so on. Made on the fabric headboard Picture

The result look like this :)

Well, if the rear view ... how strange twists the camera down. From the double bed seems single :)

Well, the bought in Ikeja Mattress 200 * 140 lay as though there is always lying!

And another angle

Source: