1501

Two days - and the modular home ready

Why publish here - read a subject about the house for about 900K and technology of its construction, as well as about a man who built a house, garage - inspired. Therefore it was decided to give the idea to the wolves just yapovtsam :)

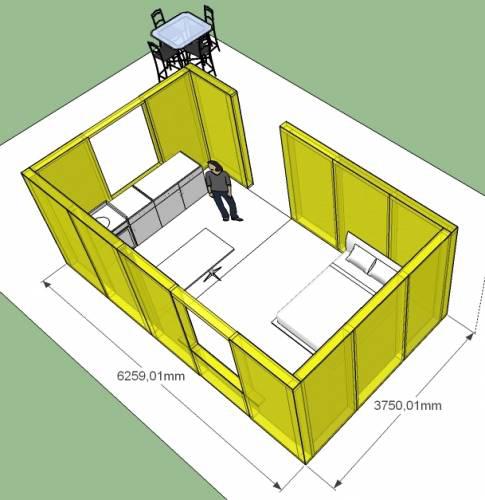

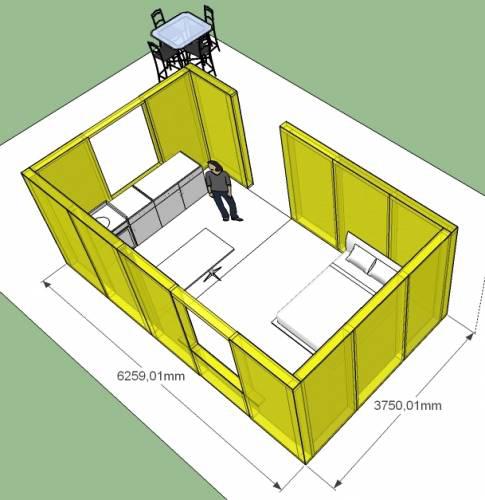

The cost price of the cabin 4x6 m ~ 1.000 $

Construction time - somewhere in 2 days ...

8 photos

Strongly inspired by the idea of modular fast-constructed housing. The problem of existing realities - the extremely low biological and environmental safety and the relatively high cost of its construction. To most of these technologies can be safely ascribe the fragility of the structure and heat-preserving properties operated facilities.

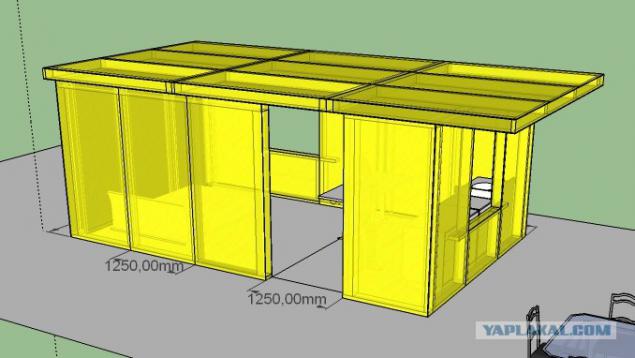

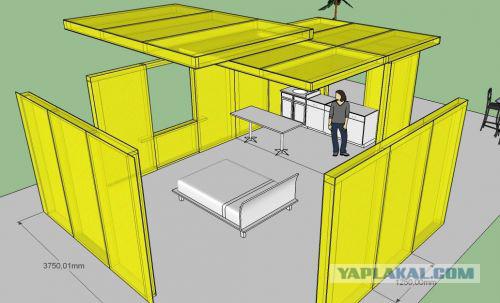

So look at the implementation of my idea. Construction of the foundation and the floor is missed intentionally. The building is easy and the subtleties on the construction of the foundation does not possess in perfection. Looks simple, but worth every thirty cheaper ...

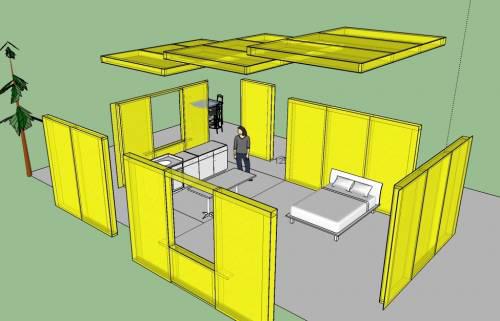

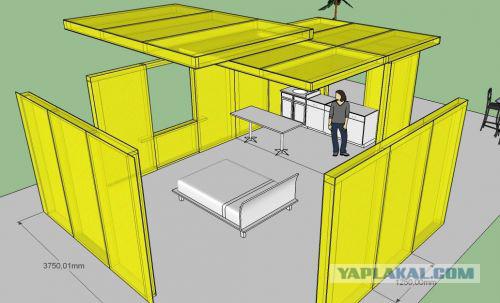

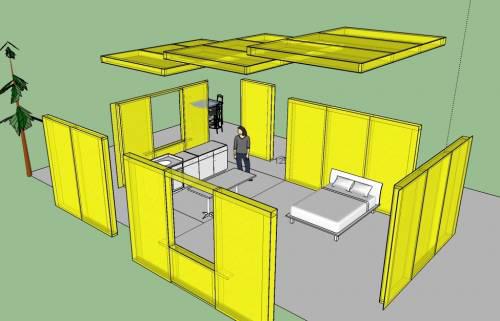

The house is built of parts, units - modules - is the wall, ceiling or roof part. This difference is probably the very concept of a modular construction, since in most cases we are talking about the module as part of the finished habitable.

MATERIAL:

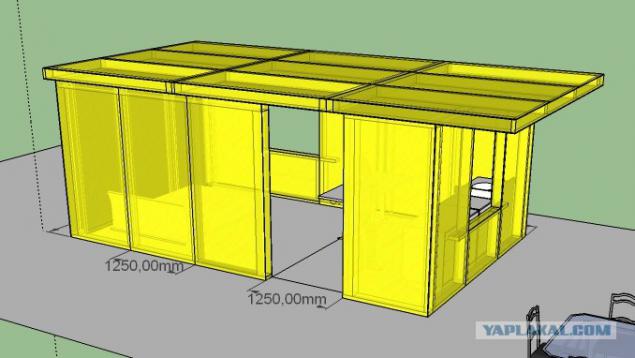

For the manufacture of OSB panel module uses the standard size 2500h1250 minimum thickness 9 mm. The essence of the choice of the thickness does not change because you can pick and three times thicker. The second component module performs BEAM width 150 mm thickness from 50 to 150 mm depending on the location. Assembling module glue + screws / staples to taste.

The market price of one OSB panels - 500 rubles, a cubic meter of timber 5000.

The most controversial moment of the entire project - thermal insulation. Its not at all. Rather, acts as thermal insulation air hermetically enclosed in blocks ~ 2400x1100. That execution modules in the form of a sealed can save on mineral wool or polystyrene foam. In short - the foam is a straight road in oncology due to phenol and other muck and mineral wool if not settle for the first winter, then pick up moisture and is an ideal heat conductor. Probably purely my misconception is not about that.

Manufacturing technology modules involves minimal operating costs. OSB is practically not changed, only the boards are cut to the desired length - that's the whole fur. process. Due to a perfectly flat surface OSB panels and boards achieve tightness when gluing them is easy. The durability of the connection depends on the type of adhesive and the amount of additional gain in the form of application of screws or staples.

This embodiment of the facade module (T3) of 3 panels. Easily expandable to 4 or down to 1 bar. Option slab walls or inserting the front door the same, only without the butt of the recess 168 mm (width of the beam 150 + 9 + 9 mm panel). Carriers, so to speak, the walls are performed even easier because they do not need to do butt recess at all, just the right amount of glue panels with cut lumber. The upper and lower rails whole over the entire length of the module. in the figure are painted blue. Lower (and possibly upper) to save enough to use 50mm median of 100 mm on the top and side 150mm

Next ready modules elementary and importantly very quickly joined into a single structure using mounting foam and screws at the joints. Manufacture modules involves organizing their production. Installation is carried out either by the customer or a team of workers. That is, the modules themselves are not made by hand, and at work - even though it is elementary.

Blocks and blocks of the ceiling of the side walls of the T3 three panels are identical. Sheathing siding or painting the walls at will, polyurea roofing or roofing material in the draft is not considered, since there will already fantasies. Themselves OSB panel as described are not afraid of moisture and do not absorb it, and if crudely assembled cabin generally can not refine.

This version of the country house, the most economical and at the same time suitable for habitation. The very idea of modules allows after its erection some time to supplement it with one or two more rooms or San uzmom - a full bath and toilet. The same principle can be built next to "guest house" or garage ...

Little House in the minimum configuration includes 3 or 4 bed, nightstand or dresser easily fit, enough space around the bed. Spacious kitchen sector large dining table and chairs did not interfere. Furniture, windows and doors are not included in the calculation, since both the windows and the door can bet every 1,000 $

Precise counting do not. If the estimate, the total applied 24 OSB panels cost 400-500 rubles and bars, of which count count can not. Total cost of the cabin 4x6 m ~ 1.000 $

For the prototype took this beauty. As seen on the photo - one room and a kitchen is very convenient)))

Posted in [mergetime] 1388542830 [/ mergetime]

Everything.

Source: http: //

The cost price of the cabin 4x6 m ~ 1.000 $

Construction time - somewhere in 2 days ...

8 photos

Strongly inspired by the idea of modular fast-constructed housing. The problem of existing realities - the extremely low biological and environmental safety and the relatively high cost of its construction. To most of these technologies can be safely ascribe the fragility of the structure and heat-preserving properties operated facilities.

So look at the implementation of my idea. Construction of the foundation and the floor is missed intentionally. The building is easy and the subtleties on the construction of the foundation does not possess in perfection. Looks simple, but worth every thirty cheaper ...

The house is built of parts, units - modules - is the wall, ceiling or roof part. This difference is probably the very concept of a modular construction, since in most cases we are talking about the module as part of the finished habitable.

MATERIAL:

For the manufacture of OSB panel module uses the standard size 2500h1250 minimum thickness 9 mm. The essence of the choice of the thickness does not change because you can pick and three times thicker. The second component module performs BEAM width 150 mm thickness from 50 to 150 mm depending on the location. Assembling module glue + screws / staples to taste.

The market price of one OSB panels - 500 rubles, a cubic meter of timber 5000.

The most controversial moment of the entire project - thermal insulation. Its not at all. Rather, acts as thermal insulation air hermetically enclosed in blocks ~ 2400x1100. That execution modules in the form of a sealed can save on mineral wool or polystyrene foam. In short - the foam is a straight road in oncology due to phenol and other muck and mineral wool if not settle for the first winter, then pick up moisture and is an ideal heat conductor. Probably purely my misconception is not about that.

Manufacturing technology modules involves minimal operating costs. OSB is practically not changed, only the boards are cut to the desired length - that's the whole fur. process. Due to a perfectly flat surface OSB panels and boards achieve tightness when gluing them is easy. The durability of the connection depends on the type of adhesive and the amount of additional gain in the form of application of screws or staples.

This embodiment of the facade module (T3) of 3 panels. Easily expandable to 4 or down to 1 bar. Option slab walls or inserting the front door the same, only without the butt of the recess 168 mm (width of the beam 150 + 9 + 9 mm panel). Carriers, so to speak, the walls are performed even easier because they do not need to do butt recess at all, just the right amount of glue panels with cut lumber. The upper and lower rails whole over the entire length of the module. in the figure are painted blue. Lower (and possibly upper) to save enough to use 50mm median of 100 mm on the top and side 150mm

Next ready modules elementary and importantly very quickly joined into a single structure using mounting foam and screws at the joints. Manufacture modules involves organizing their production. Installation is carried out either by the customer or a team of workers. That is, the modules themselves are not made by hand, and at work - even though it is elementary.

Blocks and blocks of the ceiling of the side walls of the T3 three panels are identical. Sheathing siding or painting the walls at will, polyurea roofing or roofing material in the draft is not considered, since there will already fantasies. Themselves OSB panel as described are not afraid of moisture and do not absorb it, and if crudely assembled cabin generally can not refine.

This version of the country house, the most economical and at the same time suitable for habitation. The very idea of modules allows after its erection some time to supplement it with one or two more rooms or San uzmom - a full bath and toilet. The same principle can be built next to "guest house" or garage ...

Little House in the minimum configuration includes 3 or 4 bed, nightstand or dresser easily fit, enough space around the bed. Spacious kitchen sector large dining table and chairs did not interfere. Furniture, windows and doors are not included in the calculation, since both the windows and the door can bet every 1,000 $

Precise counting do not. If the estimate, the total applied 24 OSB panels cost 400-500 rubles and bars, of which count count can not. Total cost of the cabin 4x6 m ~ 1.000 $

For the prototype took this beauty. As seen on the photo - one room and a kitchen is very convenient)))

Posted in [mergetime] 1388542830 [/ mergetime]

Everything.

Source: http: //