645

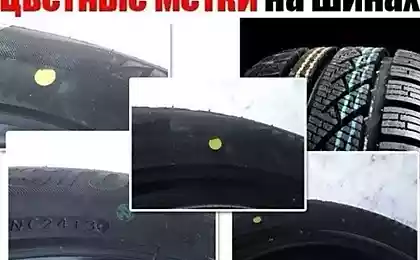

Colored labels on tires

On the Internet you can find many versions of the origin of color labels on new tires, starting from the one that all the colored labels are purely technological and end-user no significance, and before that with the help of colored labels tire manufacturers marked defective and / or Last weekend the quality control of the products.

Where is the truth?

In fact, logic dictates that inflicting any sign painted on the bus, which sooner or later will be erased (wash off) tire manufacturer suggests that the information that bears such a mark has a temporary relevance, for example, before the first installation of the tire on the disc. Here on this and must be repelled.

There are three main types of colored labels that are applied to the paint surface of the tire:

1. Coloured round spots with a diameter of 5-10 mm, coated on the outer side of the tire is closer to the rim of the disc. These spots are yellow, red, green, white, etc.

Depending on the color and the particular tire manufacturer, these spots are different information. Macular, usually marked with the lightest area of the tire. The first spot of tire service is recommended to combine with nipple wheels - so the wheel assembly will be more balanced and require less of compensating weights when balancing. Obviously, the difference in weight of different parts of the tire for high-quality new tire is scanty, and the relevance of the label lost already at the first emergency braking, so that even at the second tire service that label can not look.

Tags of any other color, or carry a similar meaning (eg, the red mark is usually marked with the hardest part of the tire, which is recommended to install in front of the nipple), or intended for use when you first install the tires on a new car at the factory, so virtually no value either for the consumer nor for the master tire are not.

2. The number (number) of the triangle (square, circle, diamond), applied white (usually) and paint on the outside sidewall of the tire.

It's a sign, is completely analogous to the Soviet stamp "OTC". An employee of the manufacturer bus carries the output quality control of finished products, and affix a stamp, which, in turn, has two fuknktsii: First, it shows that the control is made, and, secondly, it points to a specific employee-controller who is responsible for the quality control of the output. If you do not work at the plant, which produces tires for you stamp this absolutely does not mean anything.

3. The colored strip applied along the circumference of the tire in the tread or the tread itself, or within the grooves.

It is about these mysterious bands of different rumors about what they may indicate a faulty or sub-standard bus. In fact, everything is prosaic - the strips are applied solely for the purpose of rapid identification of different models and types of tires in warehouses when the warehouse worker only sees the area of tire tread due to the nature of their storage.

All

Source:

Where is the truth?

In fact, logic dictates that inflicting any sign painted on the bus, which sooner or later will be erased (wash off) tire manufacturer suggests that the information that bears such a mark has a temporary relevance, for example, before the first installation of the tire on the disc. Here on this and must be repelled.

There are three main types of colored labels that are applied to the paint surface of the tire:

1. Coloured round spots with a diameter of 5-10 mm, coated on the outer side of the tire is closer to the rim of the disc. These spots are yellow, red, green, white, etc.

Depending on the color and the particular tire manufacturer, these spots are different information. Macular, usually marked with the lightest area of the tire. The first spot of tire service is recommended to combine with nipple wheels - so the wheel assembly will be more balanced and require less of compensating weights when balancing. Obviously, the difference in weight of different parts of the tire for high-quality new tire is scanty, and the relevance of the label lost already at the first emergency braking, so that even at the second tire service that label can not look.

Tags of any other color, or carry a similar meaning (eg, the red mark is usually marked with the hardest part of the tire, which is recommended to install in front of the nipple), or intended for use when you first install the tires on a new car at the factory, so virtually no value either for the consumer nor for the master tire are not.

2. The number (number) of the triangle (square, circle, diamond), applied white (usually) and paint on the outside sidewall of the tire.

It's a sign, is completely analogous to the Soviet stamp "OTC". An employee of the manufacturer bus carries the output quality control of finished products, and affix a stamp, which, in turn, has two fuknktsii: First, it shows that the control is made, and, secondly, it points to a specific employee-controller who is responsible for the quality control of the output. If you do not work at the plant, which produces tires for you stamp this absolutely does not mean anything.

3. The colored strip applied along the circumference of the tire in the tread or the tread itself, or within the grooves.

It is about these mysterious bands of different rumors about what they may indicate a faulty or sub-standard bus. In fact, everything is prosaic - the strips are applied solely for the purpose of rapid identification of different models and types of tires in warehouses when the warehouse worker only sees the area of tire tread due to the nature of their storage.

All

Source: