633

How do cermet and crowns

Interesting photo story about the production of crowns, dentures and metal clasp. Dental technician simulates

These interiors manufacturing company! Super!

When I saw it, then laughed ... It turned out that more than serious!

The children carry out orders for the 180 clinics Omsk, plus service the entire area!

Master Alex is working diligently with the product

All work looks easy when you look from the side ... This "ease" - this is just highly qualified workers!

A two-component silicone composition. Get a green master model

The red package - the basis of the refractory mixture. All of this will fill in the form and ready green leaves refractory model!

1. The impression made by an orthopedic clinic

2. Master model is made from a cast doctor dental technician

3. Silicone mold master model

4. The model of the refractory mass. Returns dental technician, that he did it on track for the future of wax clasp

5. The cell with a wax composition and soldered Khalatnikov system is completely ready for pouring investment material and heated in an oven before pouring metal

6. The processed finished product on the master model

Here it is, the Gulf of metal funnel. When heated, the wax melts, forming channels to the Straits of hot metal

Here a woman polishes crown

The worker solder a thin wire with a laser! Through the eyepiece - superuvelichenie for accuracy

Fine work!

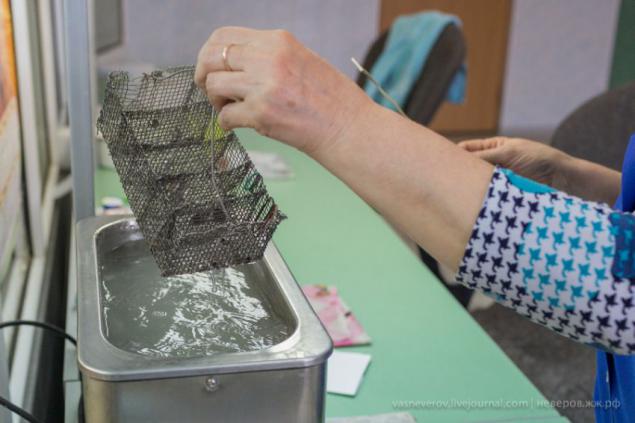

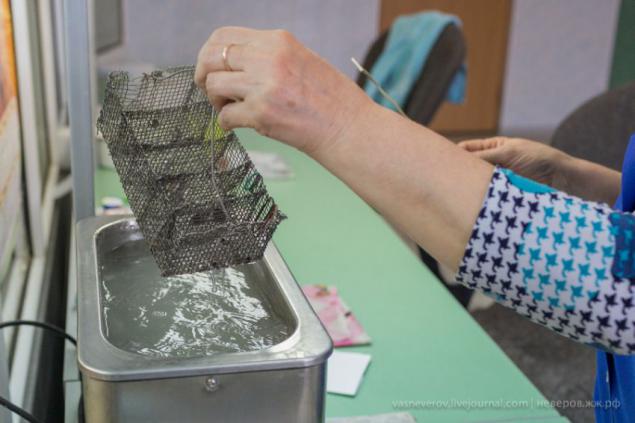

Then the crown is cleaned by ultrasound, to eliminate the slightest contamination

Ultrasonic Camera

In this apparatus, a pressure of 10 to the minus six degrees! Installation ion-plasma deposition in a high vacuum

On the left in the picture - coated titanium crowns from the plant in the previous photo. Molecular level, cathodes, anodes ... school physics!

Multiprogramme kiln

Vacuum casting machine horizontal type

Furnaces for heating. 950 degrees Celsius!

These two compressors generate compressed air for the entire production

Reuse of water - save money and care for the environment!

Source: vasneverov.livejournal.com

These interiors manufacturing company! Super!

When I saw it, then laughed ... It turned out that more than serious!

The children carry out orders for the 180 clinics Omsk, plus service the entire area!

Master Alex is working diligently with the product

All work looks easy when you look from the side ... This "ease" - this is just highly qualified workers!

A two-component silicone composition. Get a green master model

The red package - the basis of the refractory mixture. All of this will fill in the form and ready green leaves refractory model!

1. The impression made by an orthopedic clinic

2. Master model is made from a cast doctor dental technician

3. Silicone mold master model

4. The model of the refractory mass. Returns dental technician, that he did it on track for the future of wax clasp

5. The cell with a wax composition and soldered Khalatnikov system is completely ready for pouring investment material and heated in an oven before pouring metal

6. The processed finished product on the master model

Here it is, the Gulf of metal funnel. When heated, the wax melts, forming channels to the Straits of hot metal

Here a woman polishes crown

The worker solder a thin wire with a laser! Through the eyepiece - superuvelichenie for accuracy

Fine work!

Then the crown is cleaned by ultrasound, to eliminate the slightest contamination

Ultrasonic Camera

In this apparatus, a pressure of 10 to the minus six degrees! Installation ion-plasma deposition in a high vacuum

On the left in the picture - coated titanium crowns from the plant in the previous photo. Molecular level, cathodes, anodes ... school physics!

Multiprogramme kiln

Vacuum casting machine horizontal type

Furnaces for heating. 950 degrees Celsius!

These two compressors generate compressed air for the entire production

Reuse of water - save money and care for the environment!

Source: vasneverov.livejournal.com