843

How do the MC crown

And so, I think everyone (except the luckiest) of us have visited the dentist, for one reason or another, and many of us will sooner or later have to put the crown, and some have already worn them a mouthful), but what's going on behind the walls of the dentist's office Many do not know, I decided to describe the process of making sintered koronki.Post written in the informative purposes and is not an instruction).

01.

And so we get an impression from the doctor and begin the difficult path crowns.

02.

To begin manufacture of a combination of gypsum-cut model of the mouth of the patient

03.

04.

05.

after opening modeoi obtain accurate patient's teeth

06.

in this case, will be made two central incisors, are continuing the process of making a folding model

07.

08.

09.

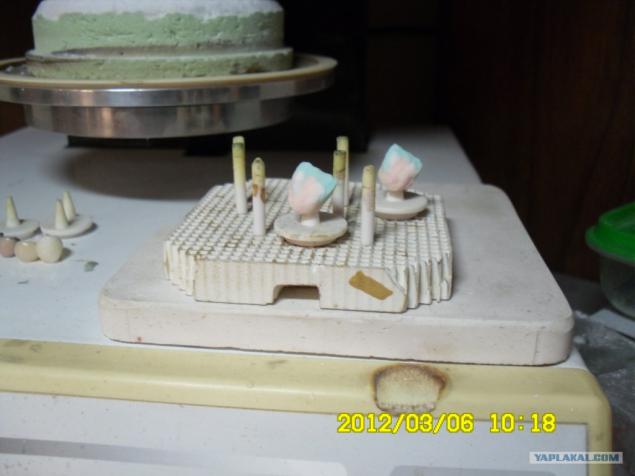

Apply several layers of varnish compensatory and start manufacturing wax blanks litya.Tak as the basis of a metal crown cap (can be any metal from stainless steel to gold alloys, and titanium), according to its cast, well, or cut out (but that is another story ) in this case is molded, and then the ceramic mass is applied in layers

10

11.

it extractors, wax thickness should not exceed 03 mm itonshe but should not otherwise shed metal

12

Cervical wax utochnyaemsheyku for a snug fit

13.

Put gates

14.

And get the ship to liteyku

14. Unfortunately miss one step, namely, the receipt and processing of castings (:

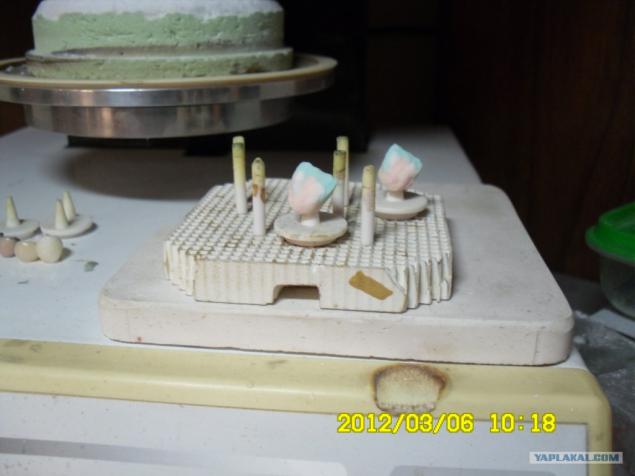

And so the casting is obtained, processed, checked with a micrometer, sandblast, degreased and applied the first layer of soil, nachinaetsya hot time with our crowns, and they otpravlyayutsya in vacuum circuit kiln

15.

16.

Apply a second layer of soil, and again in the oven

17.

Well, so look metal caps, after applying two layers of opaque (ground).

18.

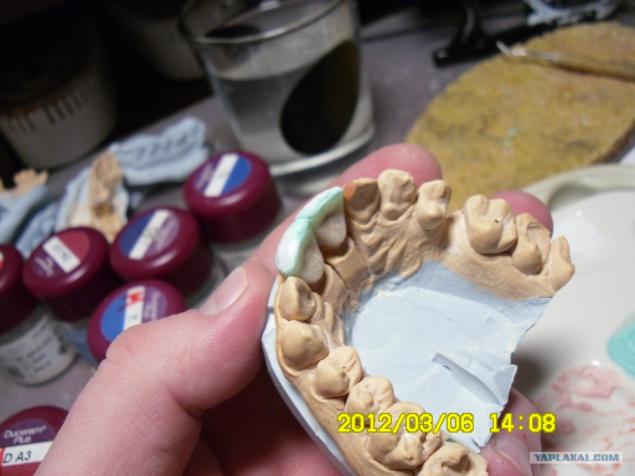

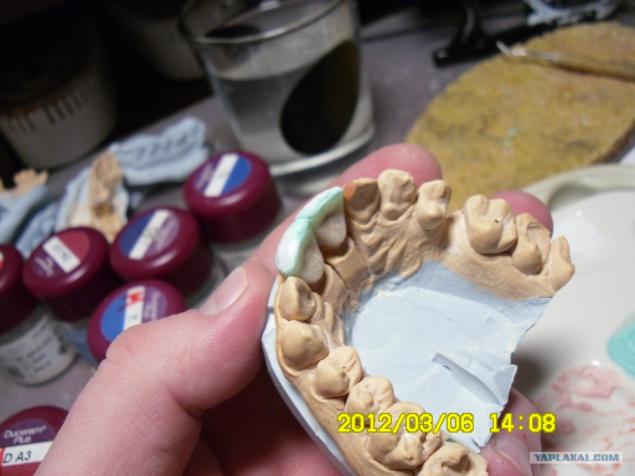

Choosing us is suitably ceramic materials, and in a special politrila, which does not allow them to dry, until the desired consistency razbovlyaem

19.

20.

Take a brush and start the creative process

21.

In the palette of the masses have such cheerful colors for easy layering, the technician saw that everywhere puts,

That's actually attach a primary form of tooth dentin

22.

23.

24.

25.

And again in the oven

26.

Here are the results of the first dentine firing, and is calculated as the weight given shrinkage primerno10-15%

27.

We proceed to the application of subsequent layers, and firing

28.

29.

Another layer and the fuser

30.

31.

last adjust the form, causes tonyusenkoy prozrachki layer to the depth of the effect

32.

Well, the final glaze firing

33.

34.

The last two photos made on a smartphone,,, crown on the second photo is not cemented, only examples,

35.

Posted in [mergetime] 1333769016 [/ mergetime]

36.Vse thank you for

Posted in [mergetime] 1333769104 [/ mergetime]

pysy when you're at the doctor in his office, he did not remember one does everything

Source:

01.

And so we get an impression from the doctor and begin the difficult path crowns.

02.

To begin manufacture of a combination of gypsum-cut model of the mouth of the patient

03.

04.

05.

after opening modeoi obtain accurate patient's teeth

06.

in this case, will be made two central incisors, are continuing the process of making a folding model

07.

08.

09.

Apply several layers of varnish compensatory and start manufacturing wax blanks litya.Tak as the basis of a metal crown cap (can be any metal from stainless steel to gold alloys, and titanium), according to its cast, well, or cut out (but that is another story ) in this case is molded, and then the ceramic mass is applied in layers

10

11.

it extractors, wax thickness should not exceed 03 mm itonshe but should not otherwise shed metal

12

Cervical wax utochnyaemsheyku for a snug fit

13.

Put gates

14.

And get the ship to liteyku

14. Unfortunately miss one step, namely, the receipt and processing of castings (:

And so the casting is obtained, processed, checked with a micrometer, sandblast, degreased and applied the first layer of soil, nachinaetsya hot time with our crowns, and they otpravlyayutsya in vacuum circuit kiln

15.

16.

Apply a second layer of soil, and again in the oven

17.

Well, so look metal caps, after applying two layers of opaque (ground).

18.

Choosing us is suitably ceramic materials, and in a special politrila, which does not allow them to dry, until the desired consistency razbovlyaem

19.

20.

Take a brush and start the creative process

21.

In the palette of the masses have such cheerful colors for easy layering, the technician saw that everywhere puts,

That's actually attach a primary form of tooth dentin

22.

23.

24.

25.

And again in the oven

26.

Here are the results of the first dentine firing, and is calculated as the weight given shrinkage primerno10-15%

27.

We proceed to the application of subsequent layers, and firing

28.

29.

Another layer and the fuser

30.

31.

last adjust the form, causes tonyusenkoy prozrachki layer to the depth of the effect

32.

Well, the final glaze firing

33.

34.

The last two photos made on a smartphone,,, crown on the second photo is not cemented, only examples,

35.

Posted in [mergetime] 1333769016 [/ mergetime]

36.Vse thank you for

Posted in [mergetime] 1333769104 [/ mergetime]

pysy when you're at the doctor in his office, he did not remember one does everything

Source: